Production of containers with recycling by twin-screw extruder

A twin-screw extruder, the technology of the extruder, which is applied in the field of container production with recycling through twin-screw extruder, can solve the problem that the extruder is difficult to be compatible with high-quality production, PET is not suitable for end use, and it is difficult to mold. and blow molding hollow objects to achieve high economic efficiency and commercial potential, low dispersion of shear and deformation ratios, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

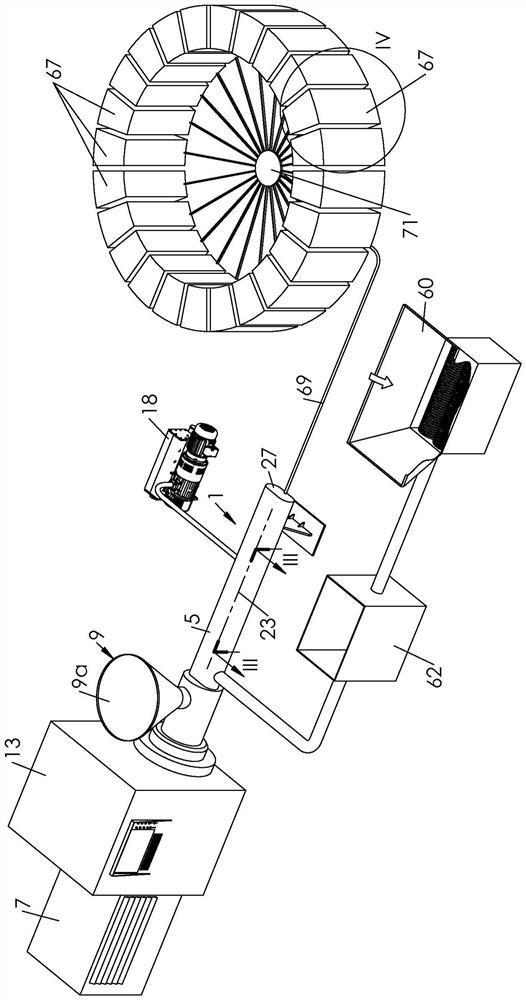

[0075] therefore, figure 2 with image 3 is a schematic diagram of a twin-screw extruder.

[0076] In the shown example of a twin-screw extruder 1, the following components are assembled on a single frame ( figure 2 ):

[0077] - screw-jacket assembly 5 with heating and cooling fittings;

[0078] - a drive group 7 comprising components which may include reduction gears, torque dividers and limiters, and the main electric motor;

[0079] - equipment 9 for material feeding (in particular metering hoppers) or for its treatment (eg degassing equipment);

[0080] - and for operating the extruder, the control cabinet 13 combines the motor converter, the starting and safety mechanisms, the regulating, commanding, displaying and measuring equipment.

[0081] The frame may be a simple support for the mechanism described above; but it may also include sheath opening means to allow access to the screws for cleaning, inspection or maintenance.

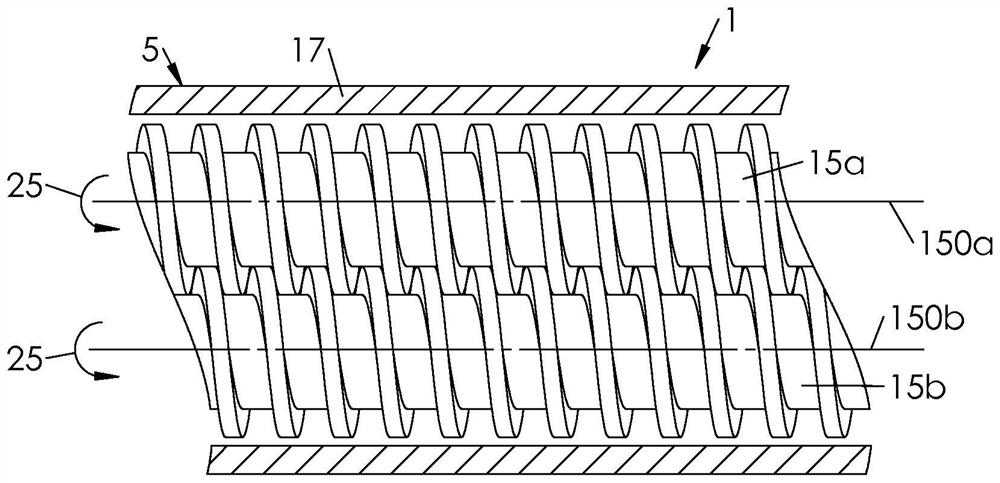

[0082] Screw-sheath assembly ( im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com