High-precision accelerometer temperature compensation method

An accelerometer and temperature compensation technology, applied in the field of inertial measurement, can solve the problems of measurement inaccuracy of accelerometer components, changes in installation errors, and inability to quantitatively measure deformation, and achieve the effect of shortening time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

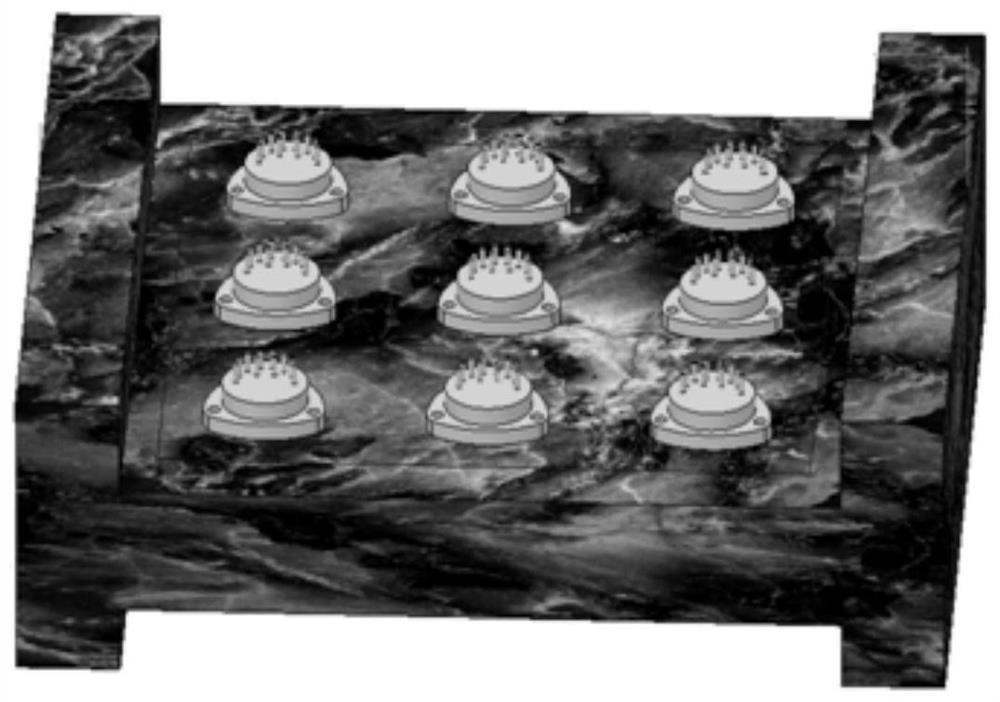

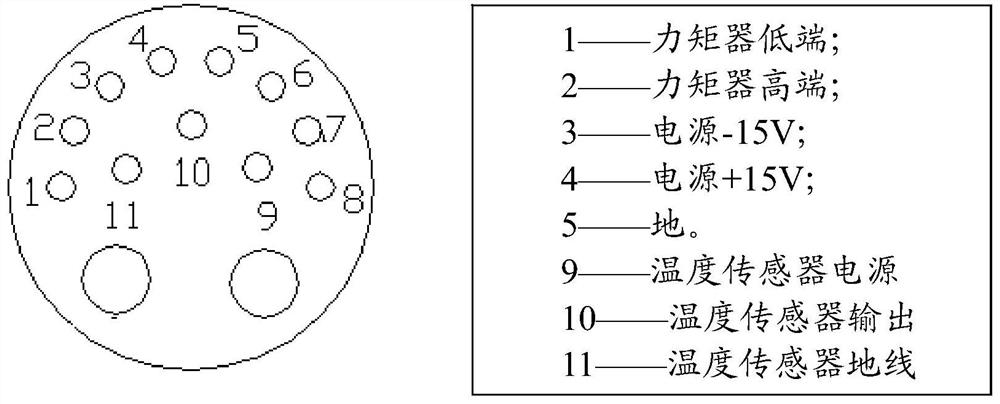

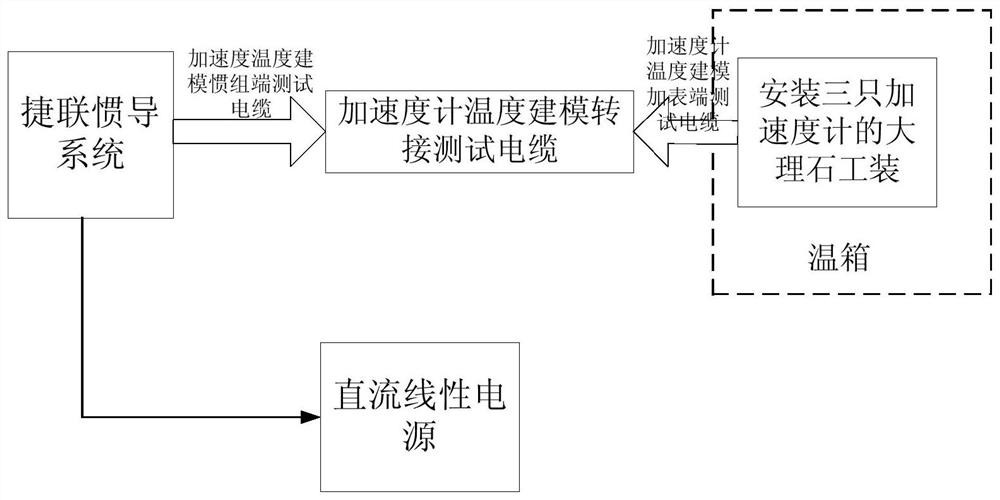

[0119] Mount an accelerometer with temperature output on an accelerometer ( figure 2 ) special marble tooling ( figure 1 ), place it in a temperature-controlled test box with a marble slab, and connect it to the external strapdown inertial navigation through a cable (the schematic diagram is as follows image 3 ), close the door of the temperature control test chamber, follow the temperature curve ( Figure 4 ) Set the control program of the temperature control test box, start the temperature control test box to start cooling, the temperature box is kept at a low temperature of -40°C for 3 hours, so that the temperature of the three accelerometer components is consistent with the temperature of the temperature control test box, turn on the power of the product, and start the strapdown During the temperature modeling test, the output pulse of the accelerometer is collected through the external strapdown inertial navigation system. The temperature of the thermostat is raised a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com