Efficient hole-expanding drill bit

A technology of reaming drill bit and drill bit, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of high maintenance cost, poor device reliability, large stress impact, etc., and achieve low maintenance cost, simple structure and high efficiency The effect of reaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

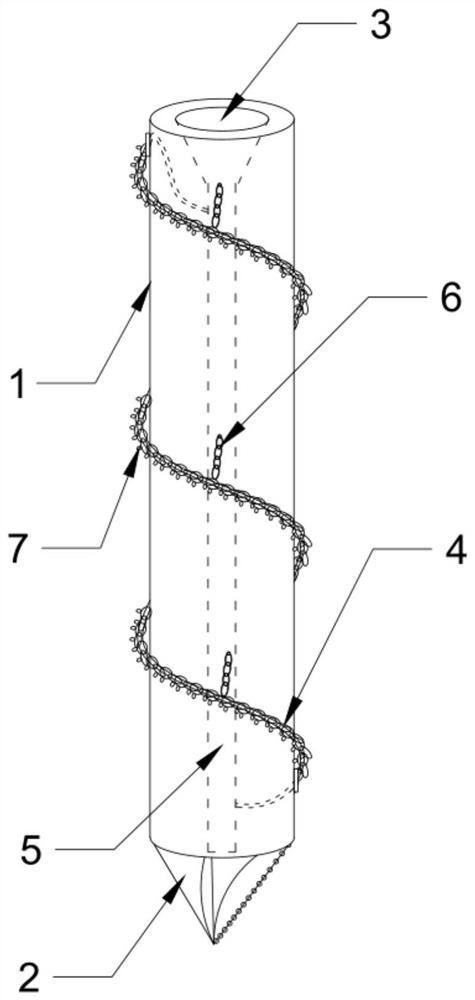

[0019] like figure 1 As shown, the present invention provides a high-efficiency reaming drill bit, including a drill bit body 1, one end of the drill bit body 1 is provided with a drill tip 2, and the other end is provided with a threaded inner hole 3 for connecting a drill rod, and the drill tip 2 is provided with a drill edge, and the drill edge is provided with a tungsten carbide diamond composite wear-resistant layer. The outer circular surface of the drill body 1 is wound with a swing chain 4, and the swing chain 4 is along the axis of the drill body 1. Arranged in a spiral shape, and the swing chain 4 is pierced with a high-pressure hose, and the two ends of the high-pressure hose are connected with the corresponding pipe joints on the drill body 1. , the pipe joint communicates with the high-pressure water channel 5, and the outer circumference of the drill body 1 is provided with traction chains 6 at intervals along the axial direction, and the end of the traction chai...

Embodiment 2

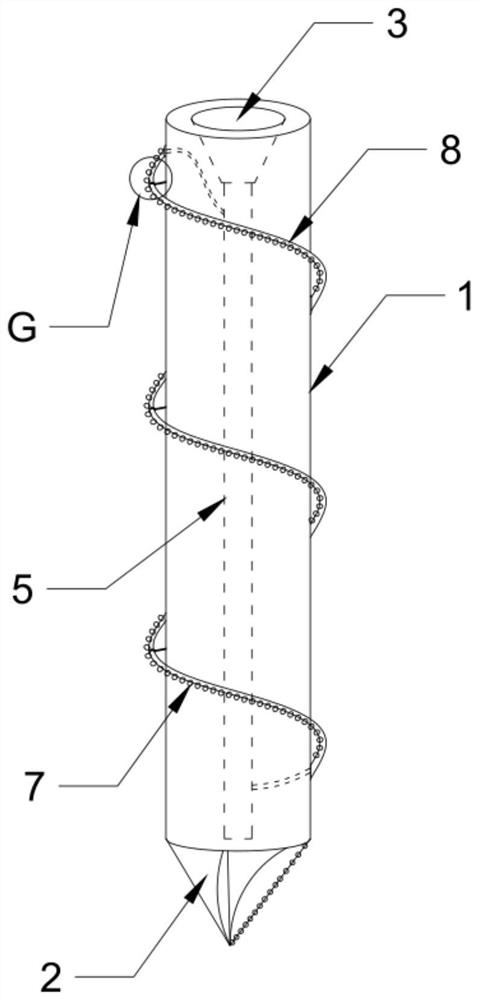

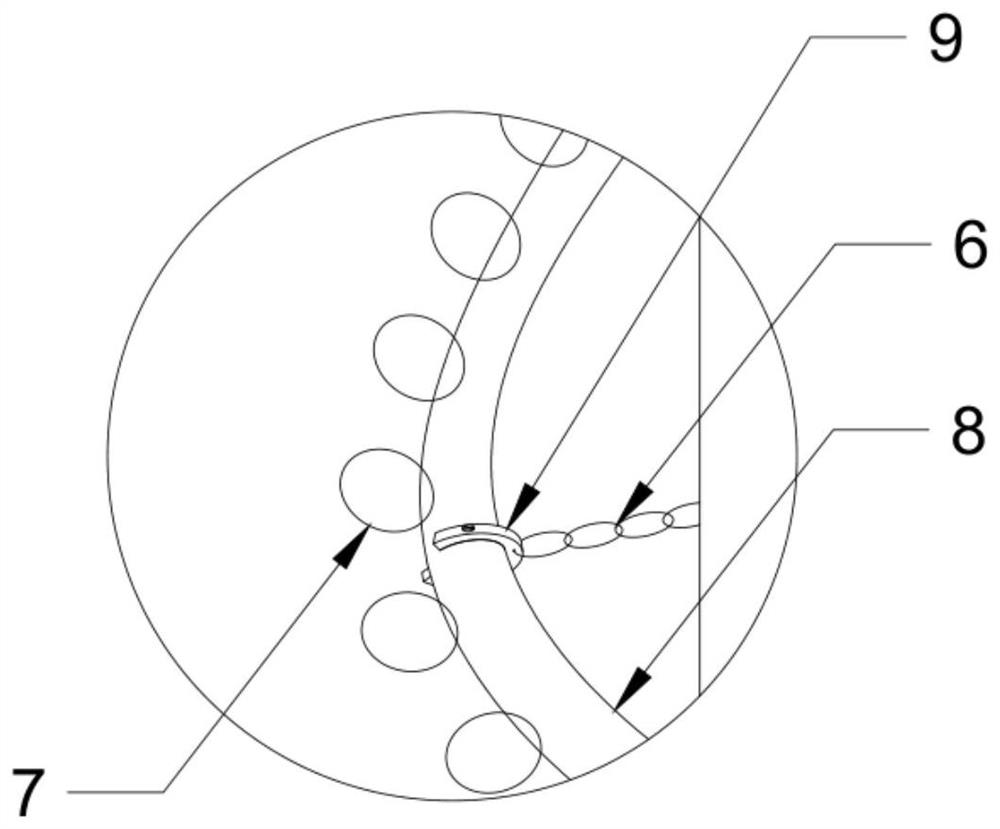

[0022] like Figure 2~3 As shown, the present invention provides a high-efficiency reaming drill bit, including a drill bit body 1, one end of the drill bit body 1 is provided with a drill tip 2, and the other end is provided with a threaded inner hole 3 for connecting a drill rod, and the drill tip 2 is provided with a drill edge, the drill edge is provided with a tungsten carbide diamond composite wear-resistant layer, the outer circular surface of the drill body 1 is wound with a steel cable 8, and the steel cable 8 is along the axial direction of the drill body. Arranged in a spiral shape, and the steel cable 8 is pierced with a high-pressure hose, the two ends of the high-pressure hose are connected with the corresponding pipe joints on the drill body 1, and the drill body 1 is provided with a high-pressure water channel 5, The pipe joint communicates with the high-pressure waterway 5, the outer circumference of the drill body 1 is provided with traction chains 6 at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com