Colored stone metal tile producing device

A technology for producing devices and metal tiles, which is applied in explosion generating devices, metal processing equipment, and roofs using tiles/slate tiles, etc., can solve problems such as inability to process different types of tiles, low production efficiency, and solidification of glue in plastic boxes. , to achieve the effect of convenient glue spraying and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

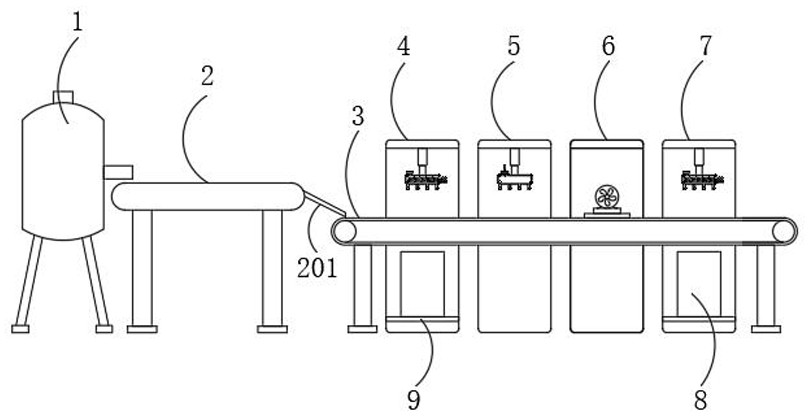

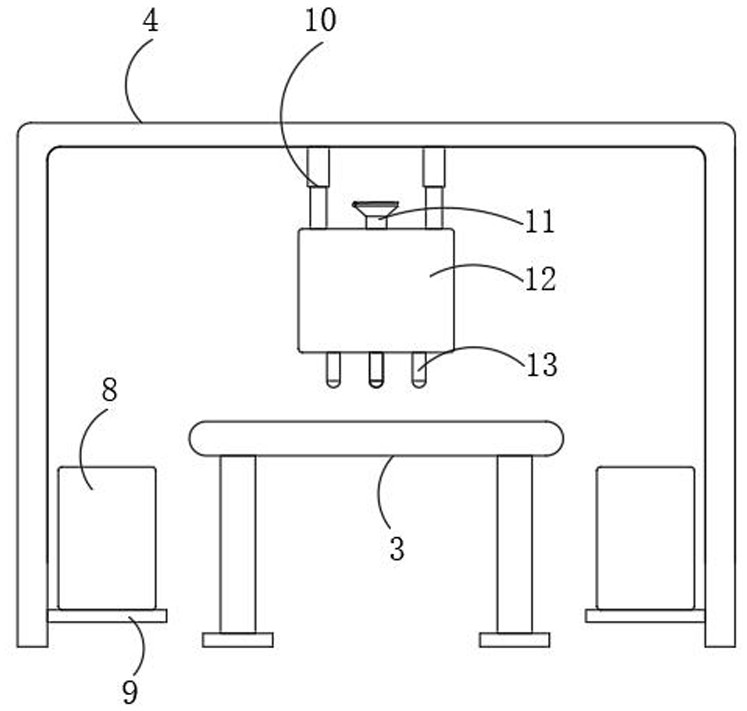

[0024] Embodiment one, with reference to figure 1 , figure 2 and Figure 5 : A production device for colored stone metal tiles, comprising a gas pressure tank 1, a semi-finished product conveying platform 2 and a conveying mechanism 3, the outer surface of the conveying mechanism 3 is respectively erected with a first U-shaped plate 4 and a second U-shaped plate 5 along the horizontal direction , the third U-shaped plate 6 and the fourth U-shaped plate 7, the inner top surface of the first U-shaped plate 4 and the fourth U-shaped plate 7 are equipped with two first electric telescopic rods 10, through the first U-shaped plate 4 Therefore, the first electric telescopic rod 10 can be activated, and the glue tank 12 can be moved downward through the activation of the first electric telescopic rod 10, and the height between the electric glue spray gun 13 and the conveying mechanism 3 can be adjusted. It is convenient to spray glue on the steel on the top of the conveying mechan...

Embodiment 2

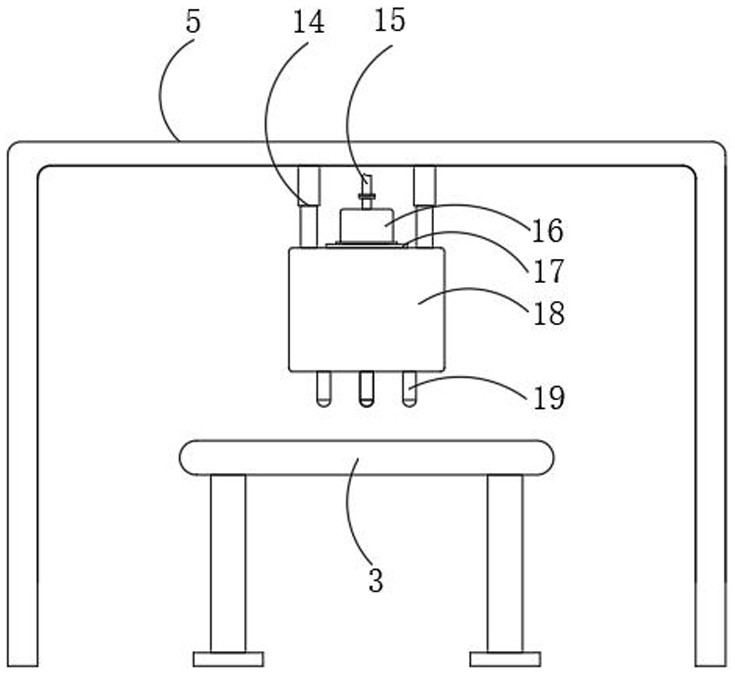

[0025] Embodiment two, refer to Figure 1-6: the inner top surface of the second U-shaped plate 5 is equipped with two second electric telescopic rods 14, the position of the second electric telescopic rods 14 can be installed and fixed through the second U-shaped plate 5, and the second electric telescopic rods 14 start, so that the sand box 18 will move down, which is convenient to adjust the height between the electric sandblasting gun 19 and the conveying mechanism 3, so that the surface of the steel can be better sandblasted, and the two second electric telescopic A sand box 18 is fixed between the bottom ends of the rods 14. The bottom of the sand box 18 is equidistantly connected and fixed with a plurality of electric sandblasting guns 19. The colored sand inside the sand box 18 can be sprayed out through the electric sandblasting guns 19. The top of the sand box 18 is fixed with a buffer plate 17 close to one side edge, and the top of the buffer plate 17 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com