A pavement asphalt mixture preparation device

A technology of asphalt mixture and preparation device, applied in the field of pavement asphalt preparation, can solve the problems of mixture gradation distortion, affecting the performance of asphalt pavement, segregation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing asphalt mixture for pavement, comprising the following steps:

[0025] 1) Sieve the aggregate to obtain coarse material, medium material and fine material. The particle size of the coarse material is not less than 10mm, the particle size of the fine material is not greater than 1mm, and the particle size of the medium material is between 10mm and 1mm; the aggregate is sieved before It can be preheated, and the preheating temperature is not higher than 150 degrees. The aggregates referred to can be aggregates that have been proportioned according to gradation, or aggregates that have not been proportioned. Coarse, medium and fine materials can be screened and proportioned according to the gradation after screening. mix.

[0026] 2) Dry the asphalt, melt part of it to obtain liquid asphalt, and pulverize the remaining asphalt to obtain powdered asphalt;

[0027] 3) After the coarse material is preheated, liquid pitch is added for stirring, and the...

Embodiment 2

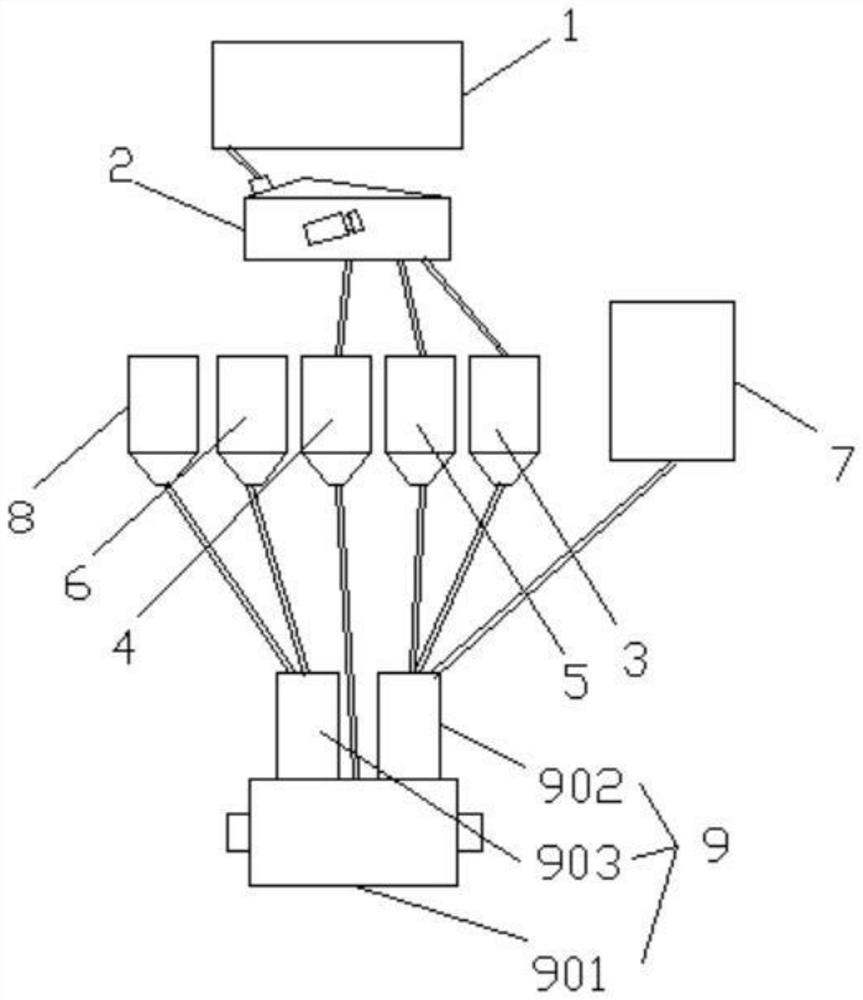

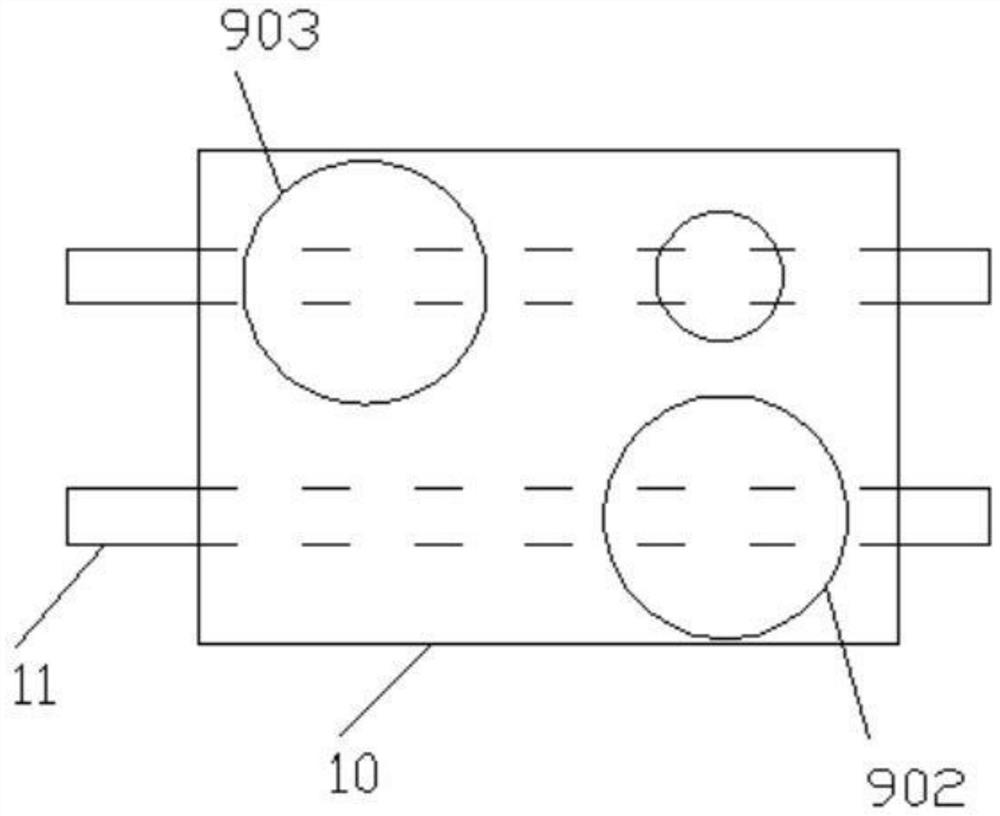

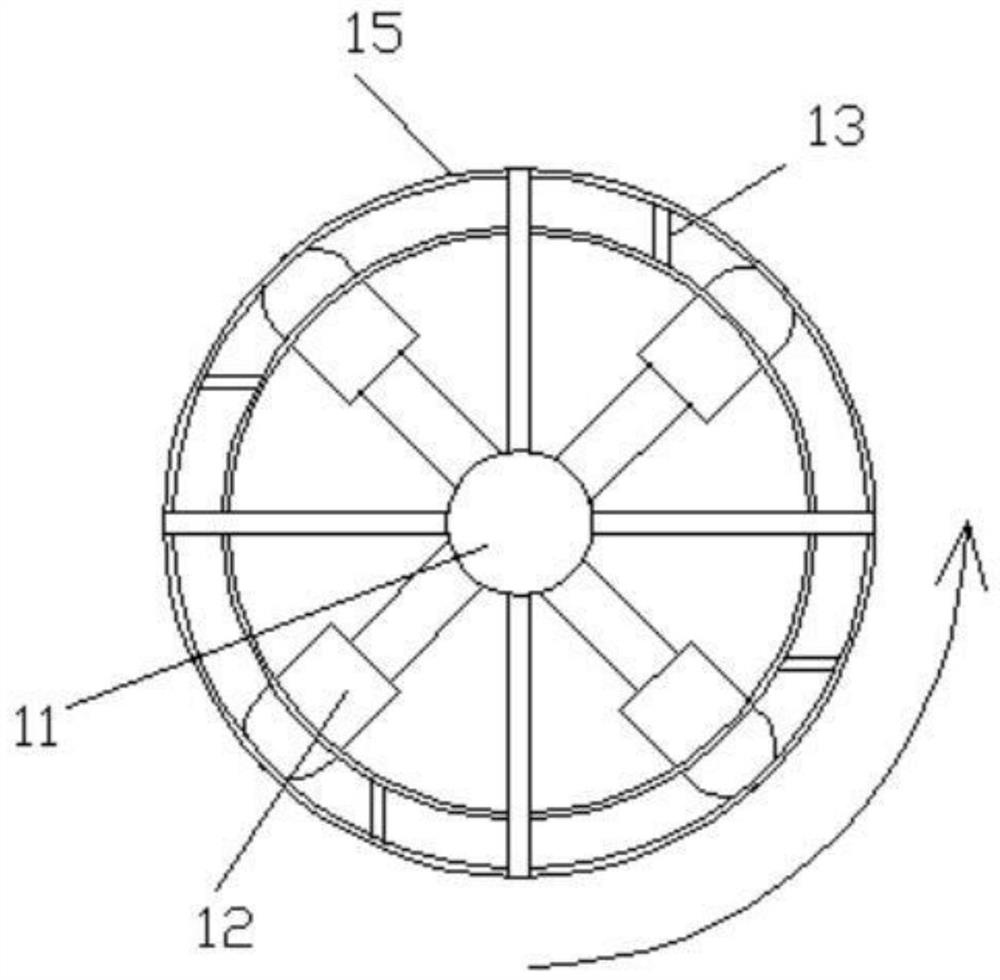

[0033] A pavement asphalt mixture preparation device, its structure is as follows Figure 1-4 As shown, it includes drying cylinder 1, screening machine 2, coarse material bin 3, medium material bin 4, fine material bin 5, ore powder bin 6, liquid asphalt storage tank 7, asphalt powder bin 8 and stirring pot 9, stirring pot 9 There is a main pot body 901, a wet mixing pot body 902 and a dry mixing pot body 903, and the outlets of the wet mixing pot body 902 and the dry mixing pot body 903 are connected to the main pot body; the outlet of the drying cylinder 1 is connected to The screening machine has 2 feed ports, the screening machine is equipped with a coarse material outlet, a medium material outlet and a fine material outlet, the coarse material outlet is connected to the coarse material bin 3, the middle material outlet is connected to the middle material bin 4, and the fine material outlet is connected to the fine material The outlets of bin 5, coarse material bin 3, fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com