High-strength and high-plasticity heterogeneous layered 5083 aluminum alloy and preparation method thereof

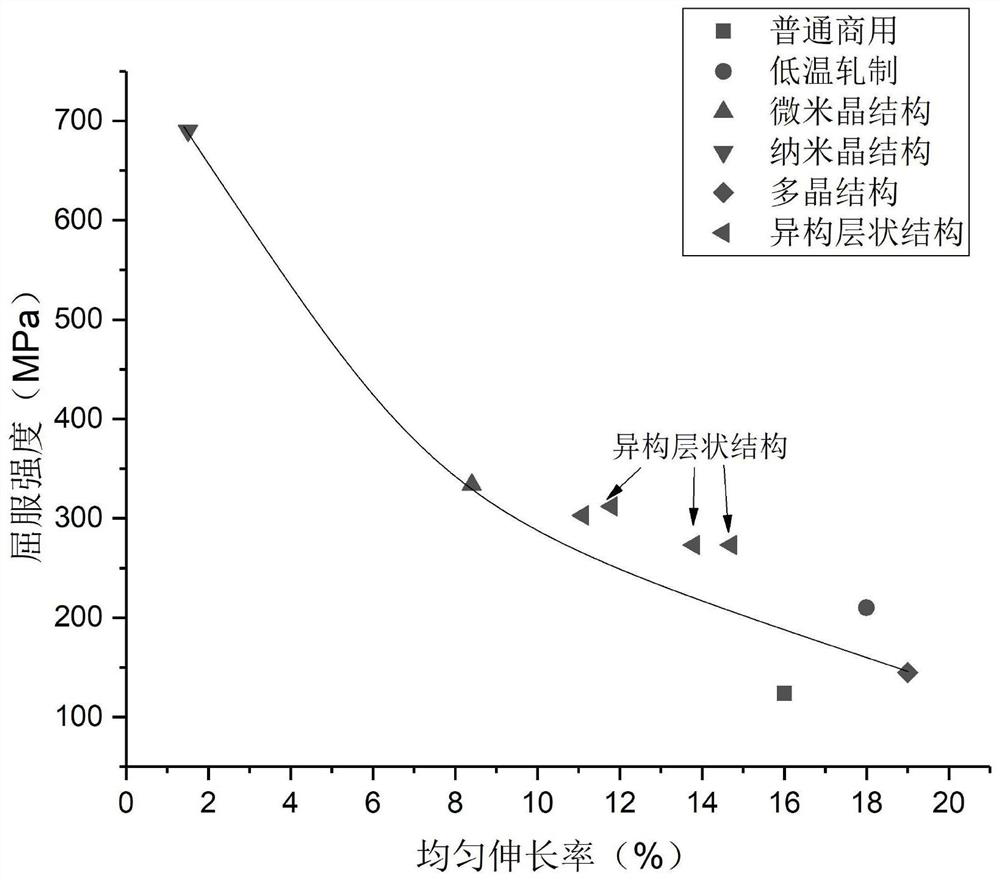

A high plasticity, aluminum alloy technology, applied in the field of aluminum alloy preparation, can solve the problems of 5083 aluminum alloy not reaching a good balance between strength and plasticity, poor alloy plasticity and toughness, and uniform elongation of only 1.5%. The method is simple, the equipment cost is low, and the effect is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

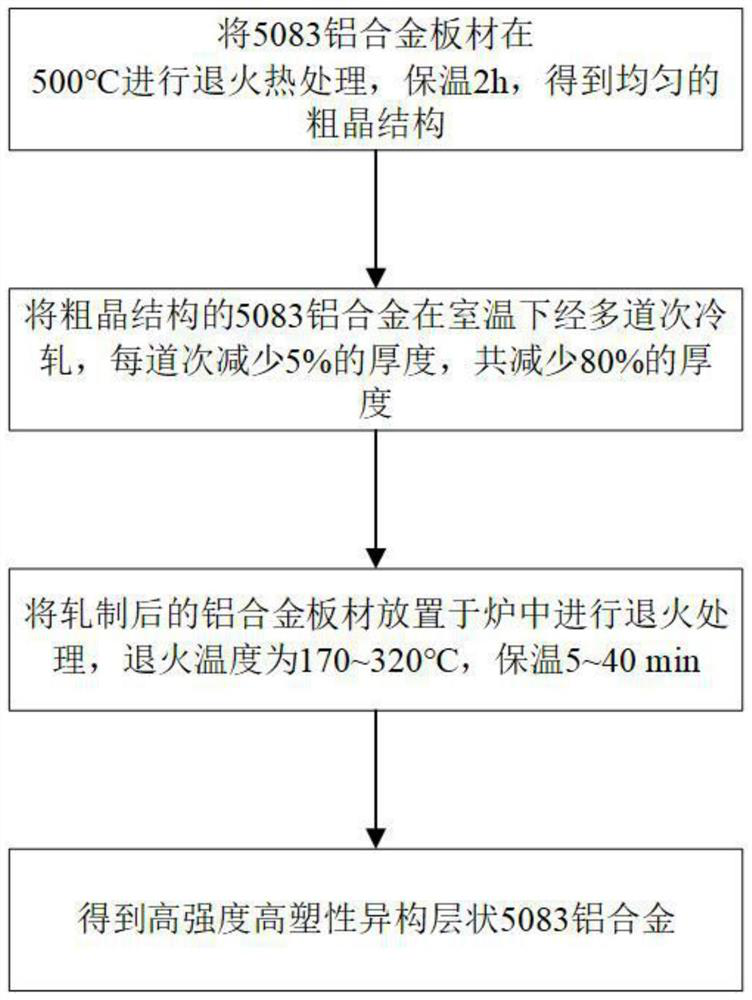

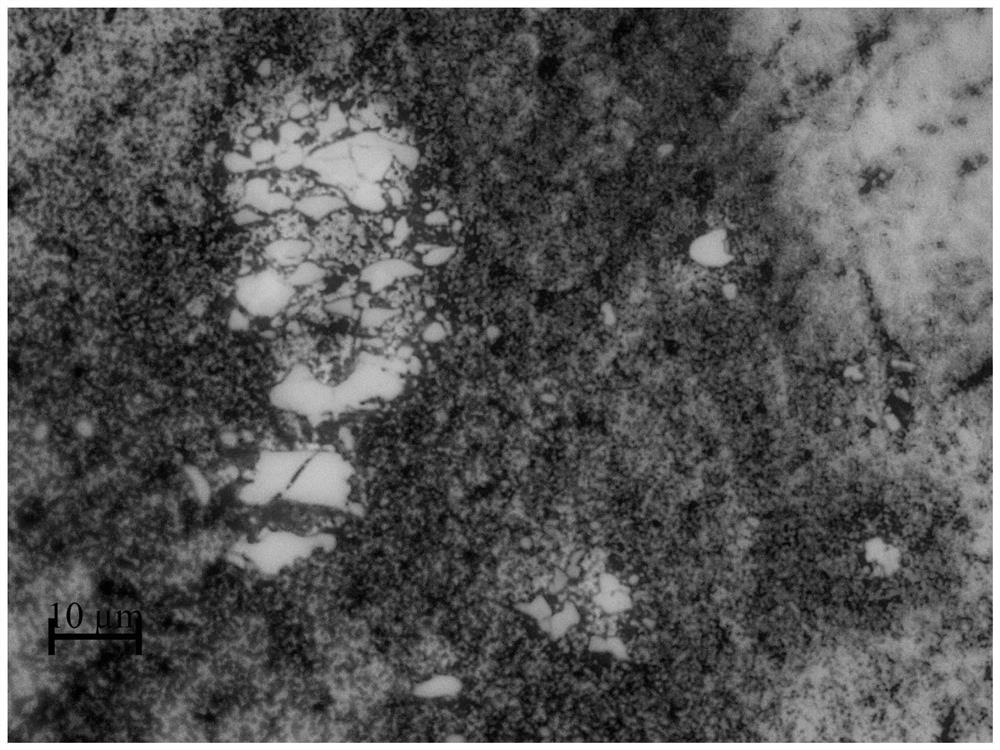

[0035] Such as figure 1 As shown, a common commercial 5083 aluminum alloy plate with a thickness of 10 mm is placed in a heating furnace, annealed at 500 ° C, and kept for 2 hours to obtain a uniform coarse-grained structure; after the 5083 aluminum alloy plate with a coarse-grained structure is released from the furnace After multiple passes of cold rolling, the thickness of each pass is reduced by 5%, and the thickness of the final aluminum alloy sheet is reduced by 80%. The thickness of the aluminum alloy sheet after final rolling is 2mm; the aluminum alloy sheet cooled to room temperature is placed Carry out recrystallization annealing treatment in the furnace, the annealing temperature is 230 ℃, keep warm for 10 minutes, obtain high strength and high plasticity heterogeneous layered 5083 aluminum alloy; through uniaxial tensile test, obtain the uniaxial The mechanical properties such as yield strength, tensile strength and elongation of the heterogeneous layered 5083 alum...

Embodiment 2

[0042] The annealing temperature and annealing time of the recrystallization annealing treatment are shown in Table 2, and the rest of the steps are the same as in Example 1, and the uniaxial tensile test is carried out on the sample after the heat treatment. Stretch curve as Figure 4 shown. The properties of the materials are shown in Table 2.

[0043] Table 2 Effect of different annealing temperatures on material properties

[0044]

Embodiment 3

[0046] The annealing temperature and annealing time of the recrystallization annealing treatment are shown in Table 2, and the rest of the steps are the same as in Example 1, and the uniaxial tensile test is carried out on the sample after the heat treatment. Stretch curve as Figure 4 shown. The properties of the materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com