A kind of high-efficiency atomized glycol dehydration device and its using method and application

A dehydration device and glycol technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of high equipment height, low dehydration efficiency, large floor space, etc., and achieve low production cost and high dehydration efficiency , the effect of low equipment height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

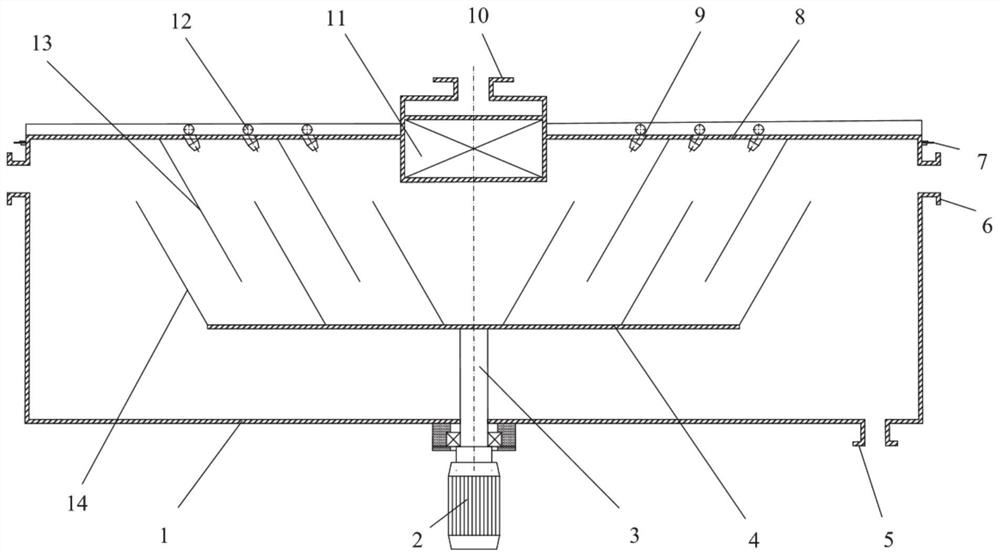

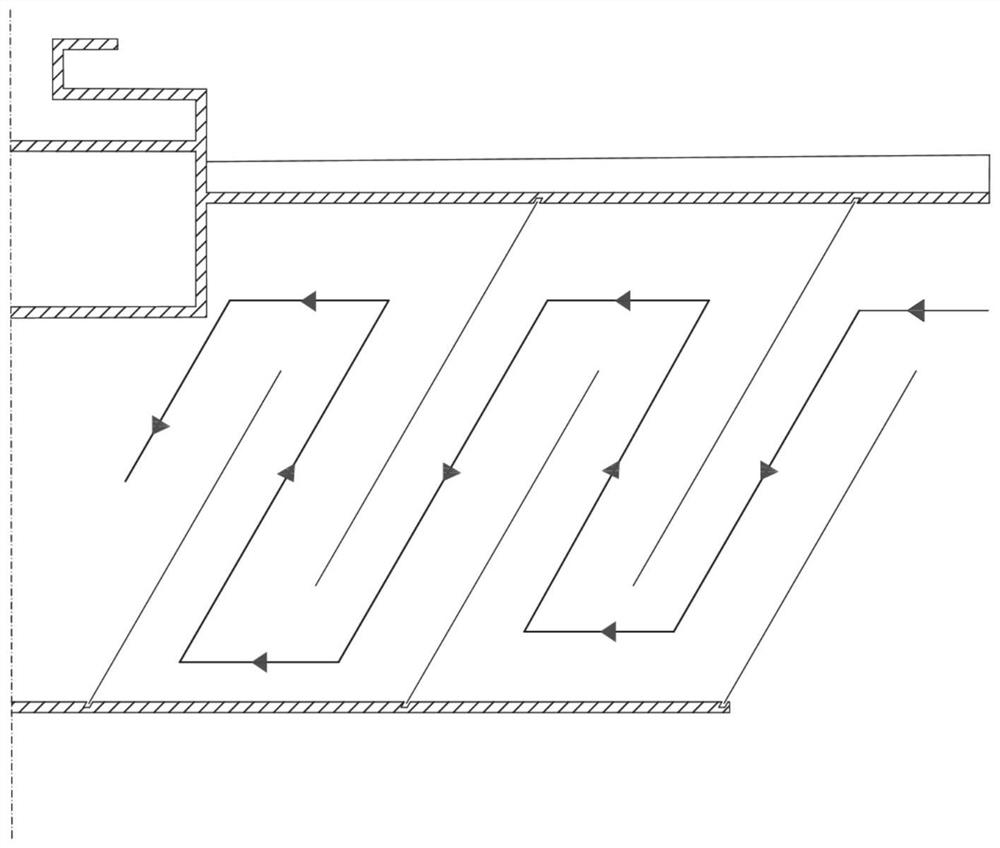

[0056] Such as Figure 1-3 As shown, the high-efficiency atomization glycol dehydration device mainly includes a glycol atomization unit and a gas-liquid contact and separation unit, and the glycol atomization unit mainly includes an atomization supply pipeline and a droplet generator; the droplet generator is based on The Laval nozzle is an ultrasonic atomizing nozzle 9 with an atomizing core; the gas-liquid contact and separation unit includes a stationary disk 8, a rotating disk 4, and dynamic baffles 14, static baffles 13 and mist traps arranged alternately between them. Device 11 ; rotating disc 4 , rotating shaft 3 , mist catcher 11 and gas outlet 10 are coaxially connected, and stationary disc 4 is welded on housing 1 . The included angle between the moving baffle ring 14 and the rotating disk 4 (near the rotating shaft 3 side) is 135°, and the included angle between the static baffle ring 13 and the stationary disk 8 (near the rotating shaft 3 side) is 45°. The ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com