Automatic laser rust removal device for convex film pressing ring of underwater missile launching shaft

A technology of laser rust removal and missile launch, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of labor-intensive cost, poor quality, low efficiency, etc., to save manpower, reduce occupied space, and facilitate movement The effect of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

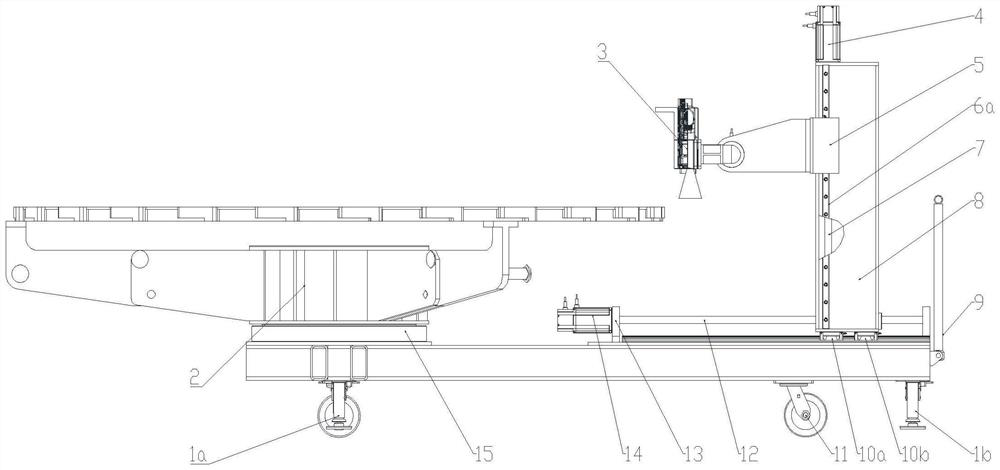

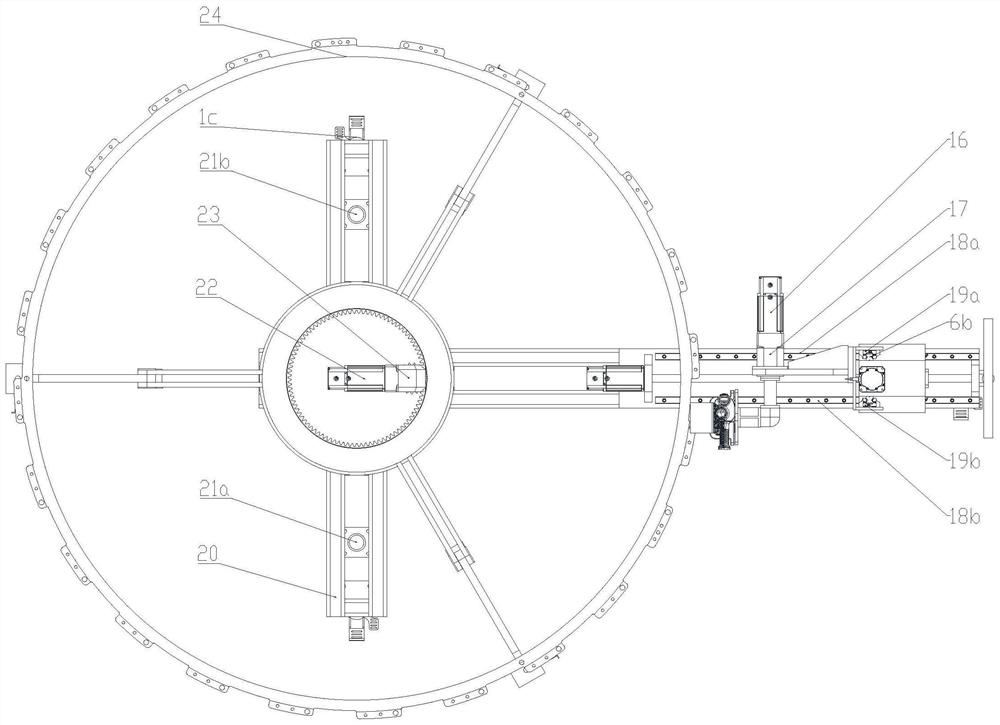

[0027] Such as Figure 1 to Figure 3 Shown, a kind of automatic laser descaling device of convex membrane pressing ring of underwater missile launching shaft, comprises the rotating support mechanism for fixing convex membrane pressing ring 24, laser descaling head 3 and driving laser descaling head action The three-degree-of-freedom moving mechanism; the rotary support mechanism includes a rotary support 15, a rotary drive device and a convex film bracket 2, and the convex film bracket 2 is fixedly connected to the outer circumference of the inner ring of the rotary support 15, and the rotary drive device and the inner ring of the rotary support The rings are connected and drive the inner ring of the rotary support 15 to drive the convex film bracket 2 to rotate relative to the outer ring of the rotary support 15, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com