Preparation method of molecular sieve membrane

一种分子筛膜、分子筛的技术,应用在化学仪器和方法、膜技术、半透膜分离等方向,能够解决低成材率、很难实验工业化应用等问题,达到增加水通量、改善亲水性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Firstly, large-particle silicalite-1 molecular sieve particles (average particle size 1.5 μm after particle size test) and small particle ZSM-5 molecular sieve particles (average particle size 500 nm after particle size test) were prepared by in-situ synthesis and microwave synthesis. And prepare 2wt.% concentration of the seed liquid.

[0027] After pretreatment, one end of the purchased α-alumina tubular porous carrier is closed, and the other end is vacuum-sucked with large particles of silicalite-1 molecular sieve seed liquid (vacuum degree 0.09MPa, suction time 30s) and dried. Coat small particles of ZSM-5 molecular sieve seed liquid (40s) and dry for later use.

[0028] To prepare ZSM-5 casting solution, mix tetrapropylammonium hydroxide (TPABr), aluminum oxide, silicon oxide, sodium oxide, sodium chloride and water, and stir vigorously to prepare a casting solution (gel). Its molar ratio is 1:84:10:100:3500:10.

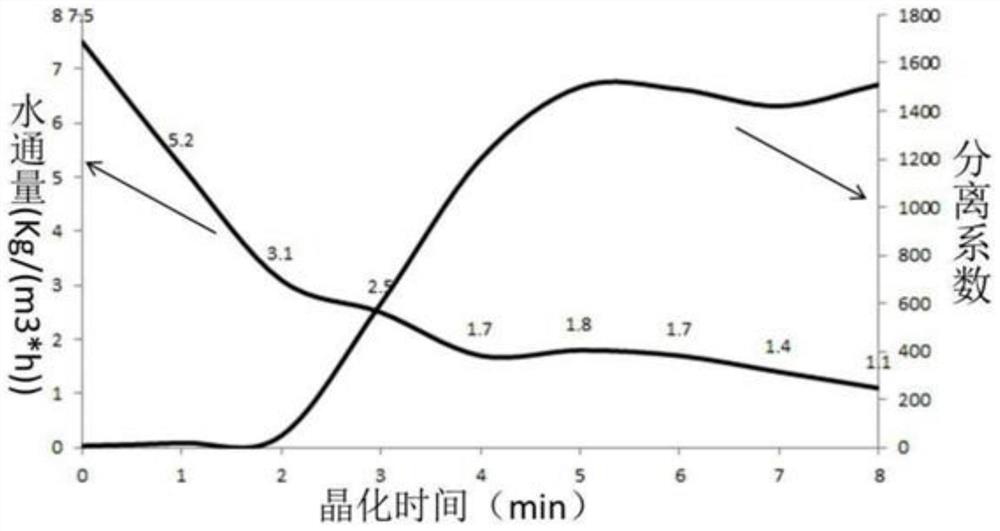

[0029]The porous carrier was placed in a reactio...

Embodiment 2

[0035] Firstly, large-particle silicalite-1 molecular sieve particles (average particle size 1.5 μm after particle size test) and small particle ZSM-5 molecular sieve particles (average particle size 500 nm after particle size test) were prepared by in-situ synthesis and microwave synthesis. And prepare 2wt.% concentration of the seed liquid. At the same time, NaA molecular sieves (average particle size 1.8 μm) were synthesized by hydrothermal method, and a seed solution with a concentration of 2wt.% was also prepared.

[0036] After pretreatment, one end of the purchased α-alumina tubular porous carrier is closed, and the other end is vacuum-sucked with large particles of silicalite-1 molecular sieve seed liquid (vacuum degree 0.09MPa, suction time 30s) and dried. Coat small particles of ZSM-5 molecular sieve seed liquid (40s) and dry for later use.

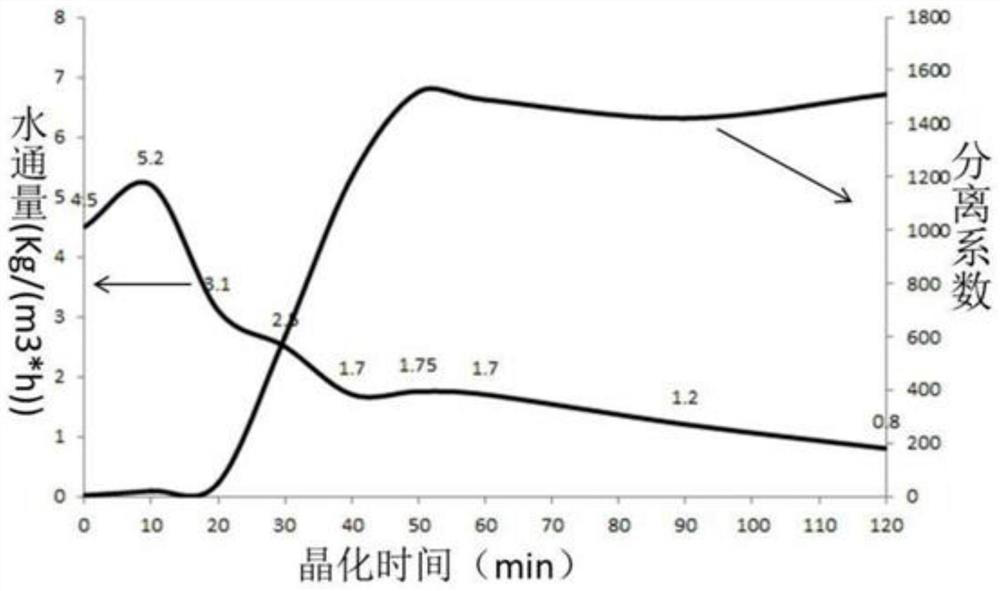

[0037] To prepare ZSM-5 casting solution, mix tetrapropylammonium hydroxide (TPABr), aluminum oxide, silicon oxide, sodium ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com