An Intelligent Power Supply System for In-situ Microwave Heating Machine

A power supply system, microwave heating technology, applied in microwave heating, electric/magnetic/electromagnetic heating, electrical components, etc., can solve the problem of centralized heat dissipation of microwave power supply, and achieve the effect of meeting construction requirements and efficient microwave power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

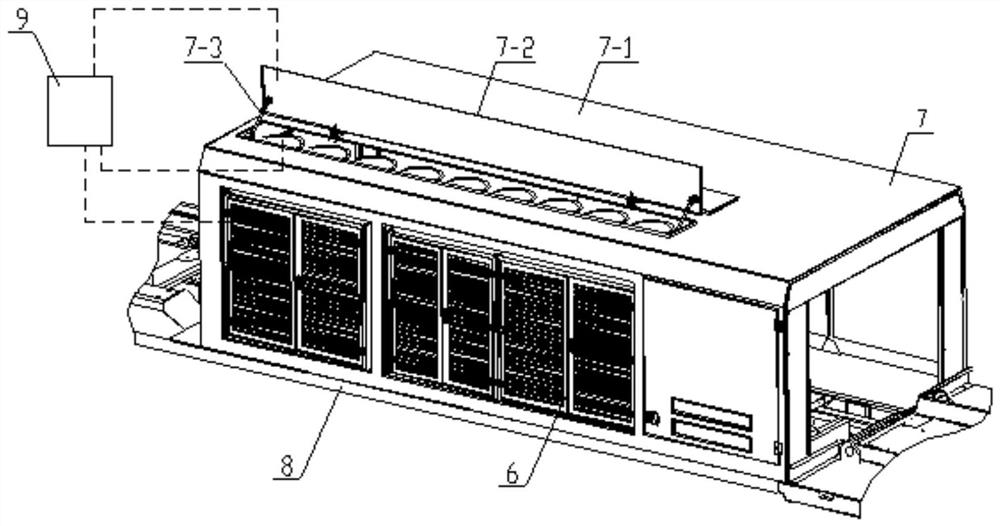

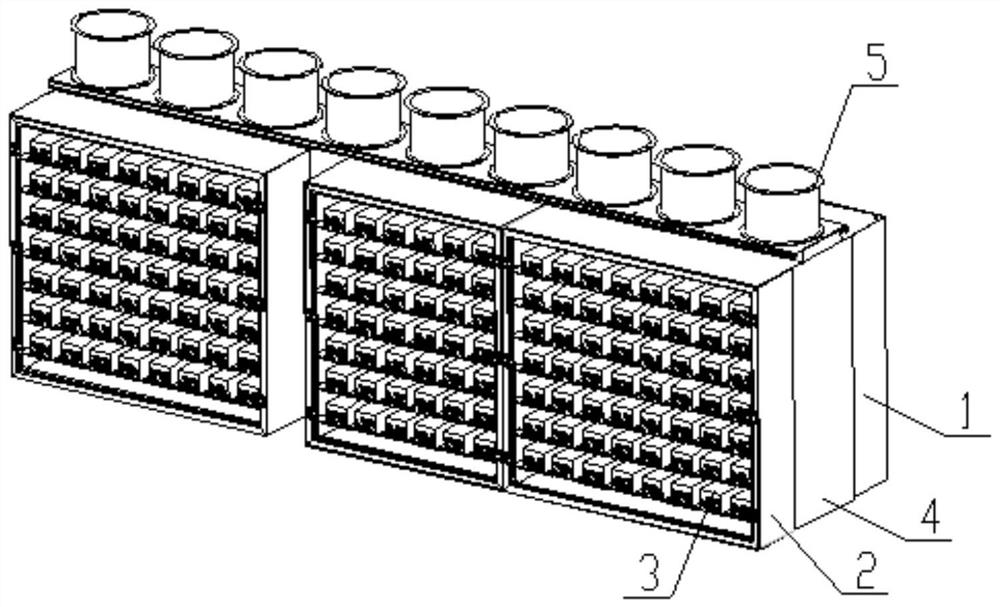

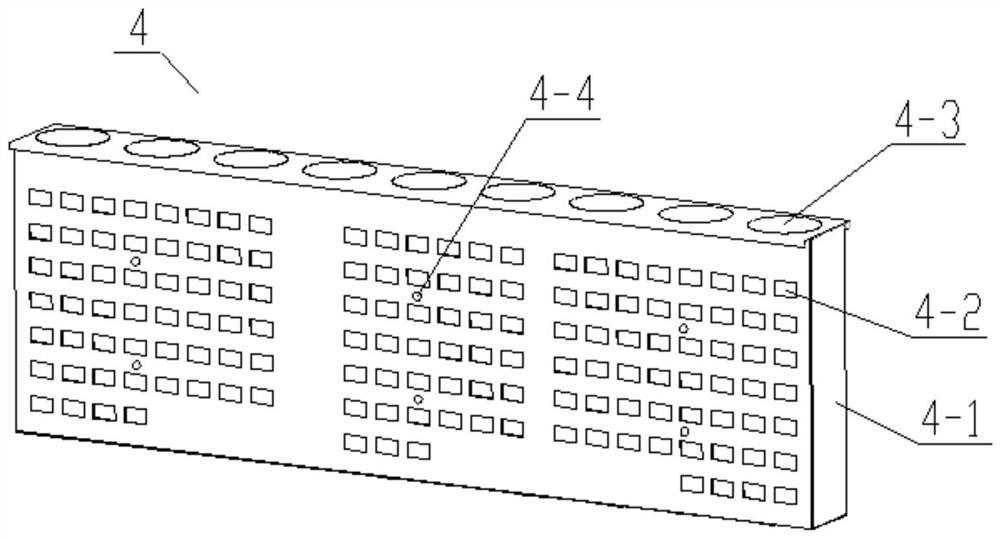

[0031] Such as Figure 1-3 As shown, an in-situ microwave heating machine intelligent power supply system includes a control system 9, an outer cover 7 and an inner power cabinet 1, an outer power cabinet 2 and an air duct 4 located inside the outer cover 7; the inner power cabinet 1 and the outer The power supply cabinet 2 is provided with a number of microwave power supplies 3 arranged in an array, and the control system 9 is connected to each microwave power supply 3 and detects and controls the working state of the microwave power supply 3 in real time; the air duct 4 is fixed on the inner power supply cabinet 1 and Between the external power supply cabinets 2, air inlets 4-2 corresponding to the microwave power supplies 3 of the internal power supply cabinet 1 and the external power supply cabinet 2 are respectively provided on both sides of the air duct 4, and the top of the air duct 4 is provided with The air outlet 4-3 connected with the air inlet 4-2 and the fan 5 con...

Embodiment 2

[0038] Such as Figure 1-3 As shown, an in-situ microwave heating machine intelligent power supply system includes a control system 9, an outer cover 7 and an inner power cabinet 1, an outer power cabinet 2 and an air duct 4 located inside the outer cover 7; the inner power cabinet 1 and the outer The power supply cabinet 2 is provided with a number of microwave power supplies 3 arranged in an array, and the control system 9 is connected to each microwave power supply 3 and detects and controls the working state of the microwave power supply 3 in real time; the air duct 4 is fixed on the inner power supply cabinet 1 and Between the external power supply cabinets 2, air inlets 4-2 corresponding to the microwave power supplies 3 of the internal power supply cabinet 1 and the external power supply cabinet 2 are respectively provided on both sides of the air duct 4, and the top of the air duct 4 is provided with The air outlet 4-3 communicated with the air inlet 4-2 and the fan 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com