Etching equipment and etching method

An etching equipment and technology to be etched, applied in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve the problems of low etching uniformity, high power consumption, spare parts cost and large maintenance workload. , to achieve the effect of reducing unevenness, improving yield, saving spare parts cost and maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

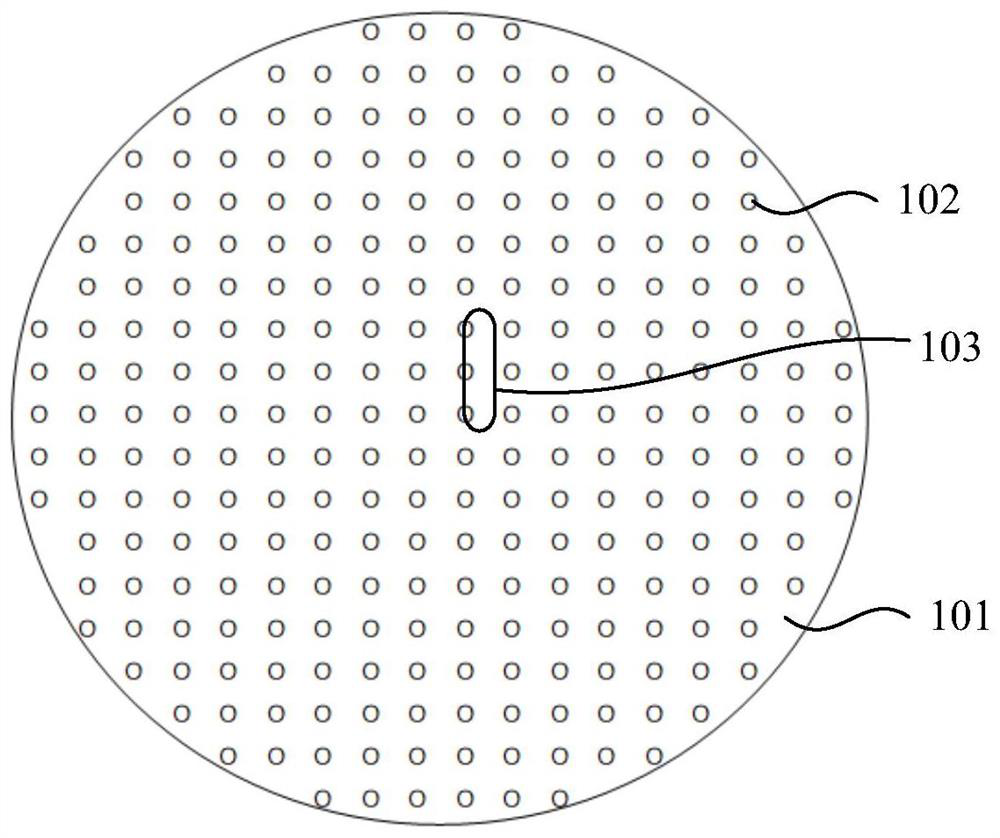

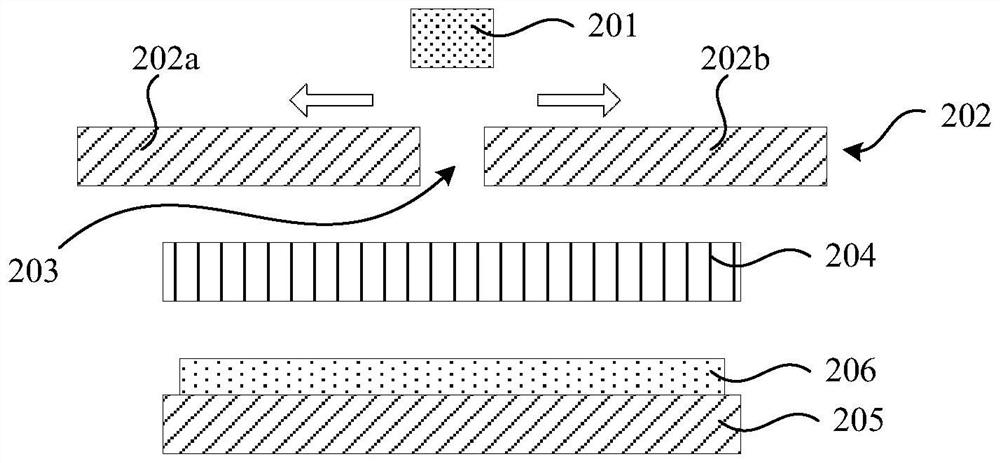

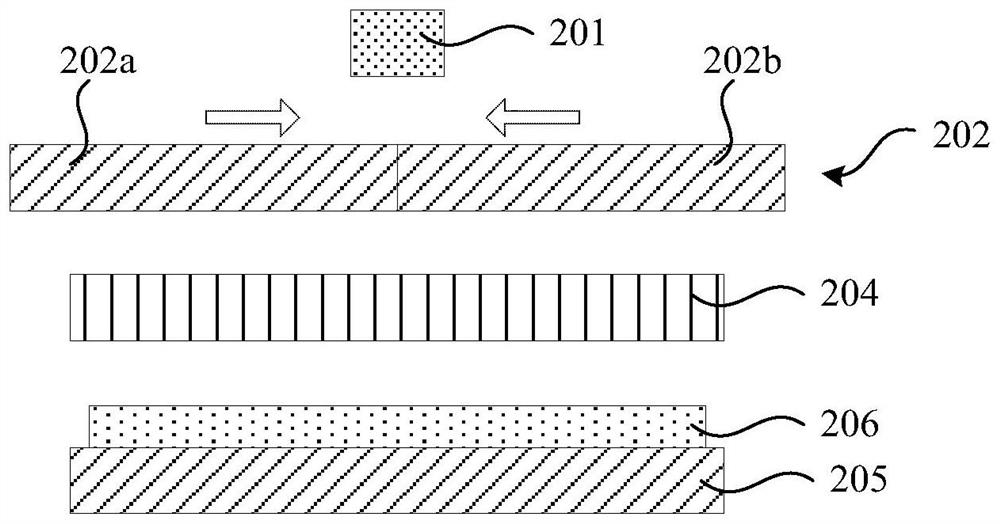

[0057] An etching device is provided in this embodiment, please refer to figure 2 and image 3 , is shown as a structural schematic diagram of the etching equipment, including a plasma generator 201, a flow plate 204, a shield assembly 202 and a wafer moving assembly 205, wherein the plasma generator is used to generate plasma to be etched The wafer 206 is etched; the uniform flow plate 204 is arranged below the plasma generator 201, and includes a body 204a and a plurality of through holes 204b for allowing the plasma to pass through the body 204a (see subsequent Figure 5 ); the baffle plate assembly 202 can be opened and closed between the plasma generator 201 and the even flow plate, wherein, when the baffle plate assembly 202 is closed (such as image 3 shown), the even flow plate 204 is completely covered under the baffle plate assembly 202, when the baffle plate assembly 202 is opened (as figure 2 As shown), a window 203 is formed to expose a part of the uniform flo...

Embodiment 2

[0070] An etching method is provided in this embodiment, please refer to Figure 7 , shown as a process flow diagram of the etching method, including the following steps:

[0071] S1: Open the baffle plate assembly to form a window to expose a part of the flow plate, so that the plasma generated by the plasma generator reaches the flow plate through the window;

[0072] S2: Use the wafer moving component to carry the wafer, and drive the wafer to move, so that the area to be etched of the wafer passes through the area below the part of the uniform flow plate exposed by the window, and is passed through the uniform flow plate plasma etching.

[0073] Specifically, the shading panel assembly adopts an openable and closable type. Such as figure 2 As shown, when the baffle plate assembly 202 is opened, a window 203 is formed to expose a part of the uniform flow plate 204, so as to allow the plasma to reach the uniform flow plate 204 through the window 203; image 3 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com