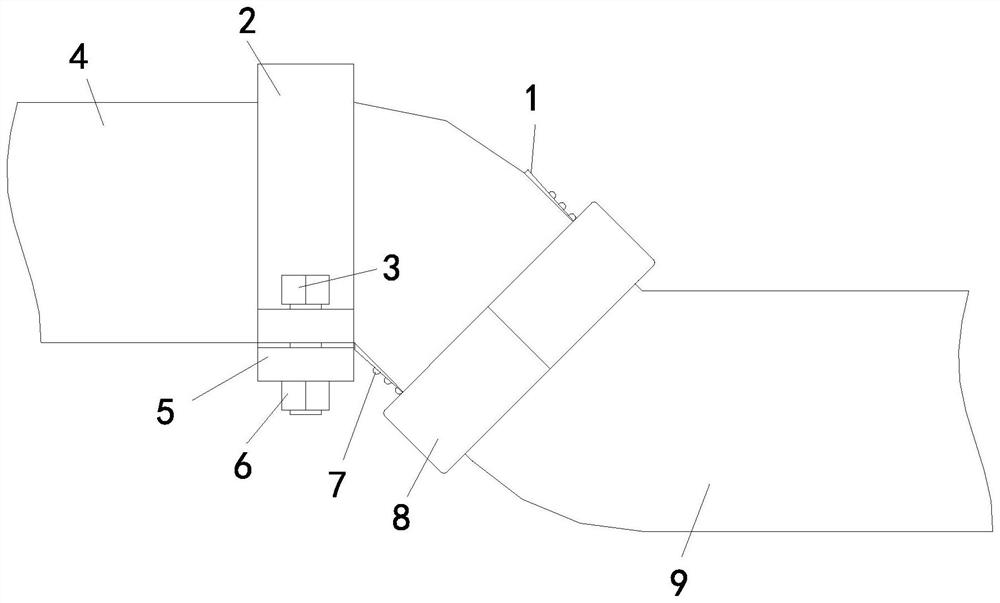

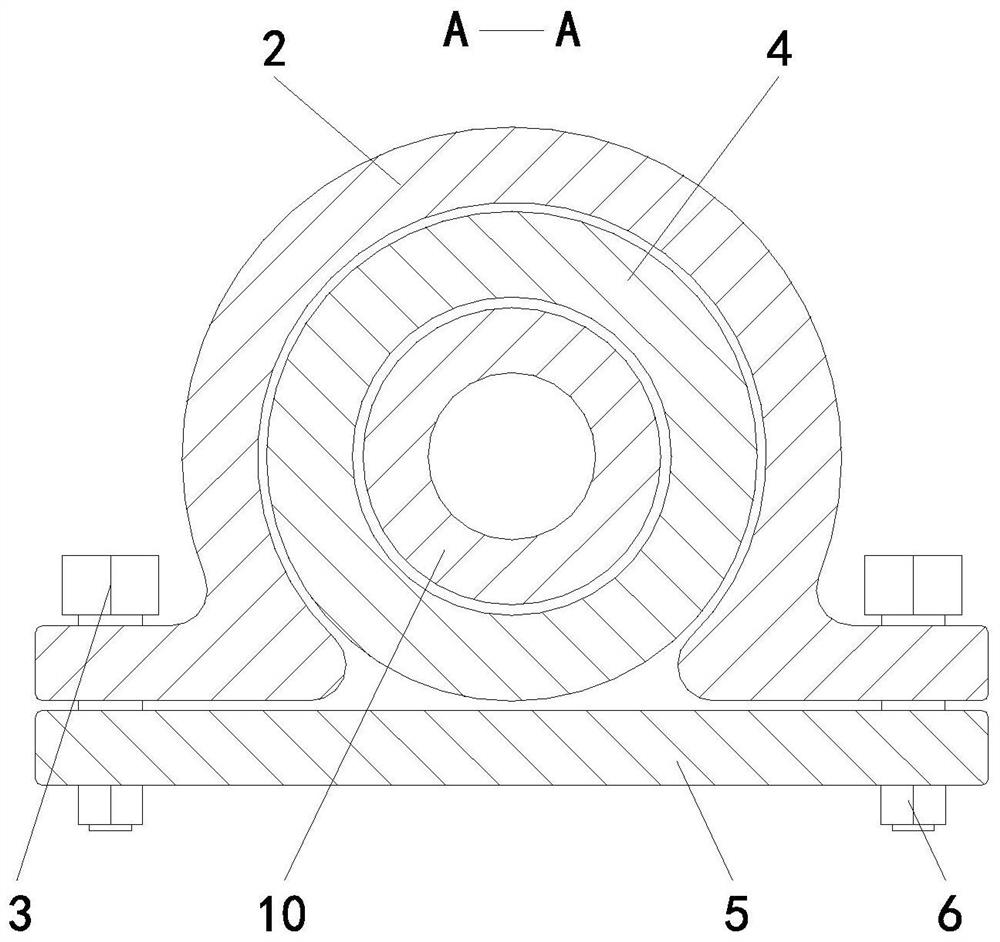

Ultra-high molecular weight polyethylene composite pipe

A polyethylene composite pipe, ultra-high molecular weight technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of looseness and slippage, water leakage angle recommendation at the interface, etc., to avoid looseness and slippage, good sealing, The effect of avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

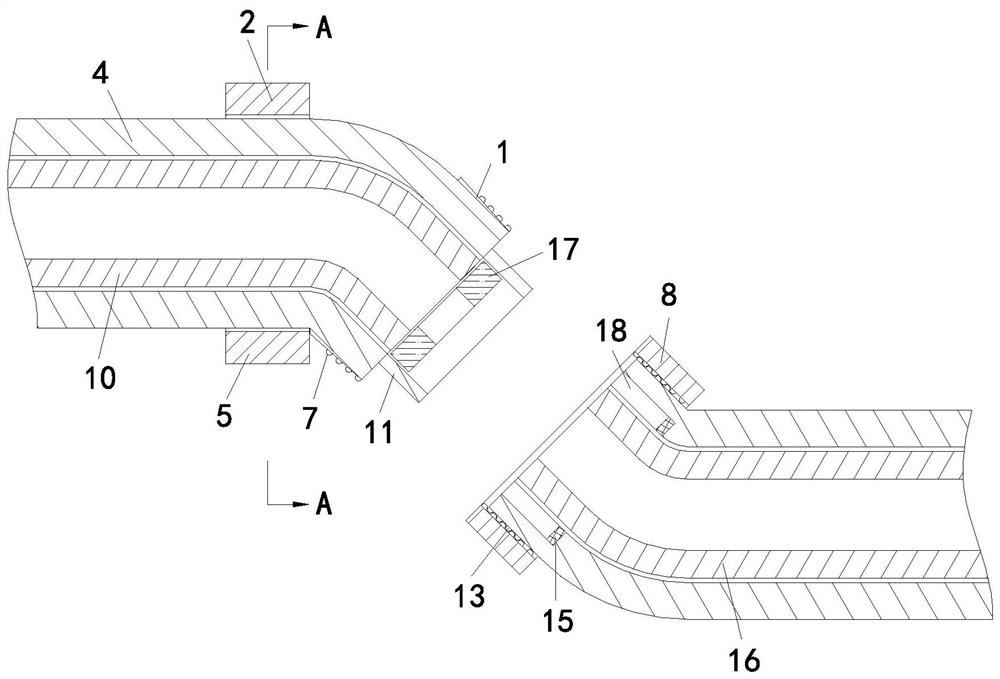

[0029] As an embodiment of the present invention, a buffer groove 19 is provided on the outer side of the waterproof plug 17; the cross section of the buffer groove 19 is a V-shaped structure; When working, the waterproof plug 17 is easily bulged and cracked at the middle position during the long-term extrusion process. Therefore, the present invention provides a buffer groove 19 on the outside of the waterproof plug 17 during the impact process. The position is the first place to be compressed, so that the deformation occurs in advance, so that the two sides of the buffer groove 19 are squeezed and fitted, while ensuring the sealing performance, it is ensured that the middle part of the waterproof plug 17 will not bulge and crack, which will cause the use of The service life is reduced, which further reduces the possibility of water leakage at the interface; and the buffer groove 19 of the V-shaped structure can deform faster when under pressure, improve the buffer effect and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com