Methods and systems to control fuel scavenging in a split exhaust engine

A technology for engine cylinders and engines, applied in charging systems, engine components, combustion engines, etc., can solve problems such as knocking, knocking problems, and increasing engines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

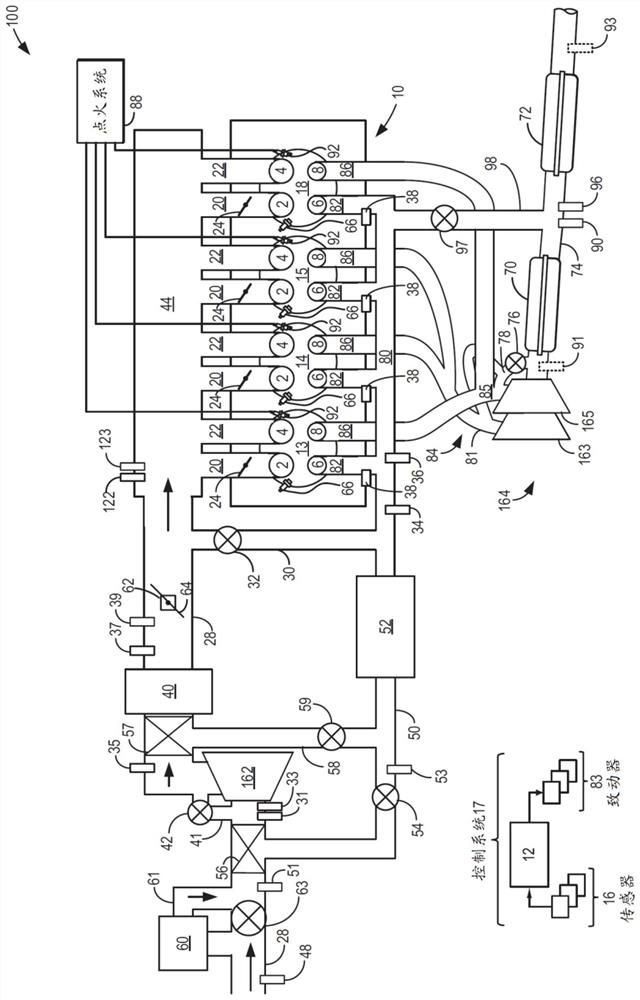

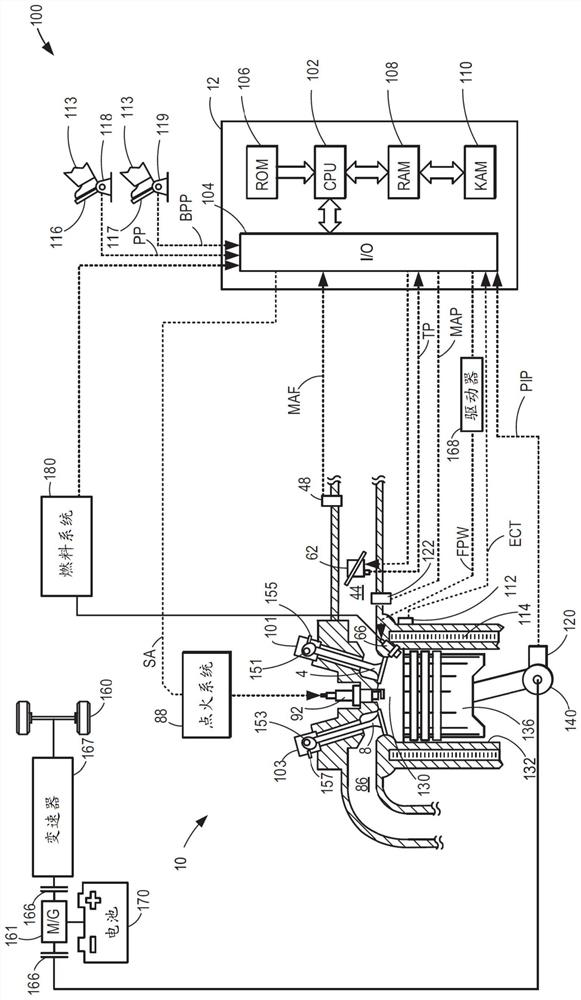

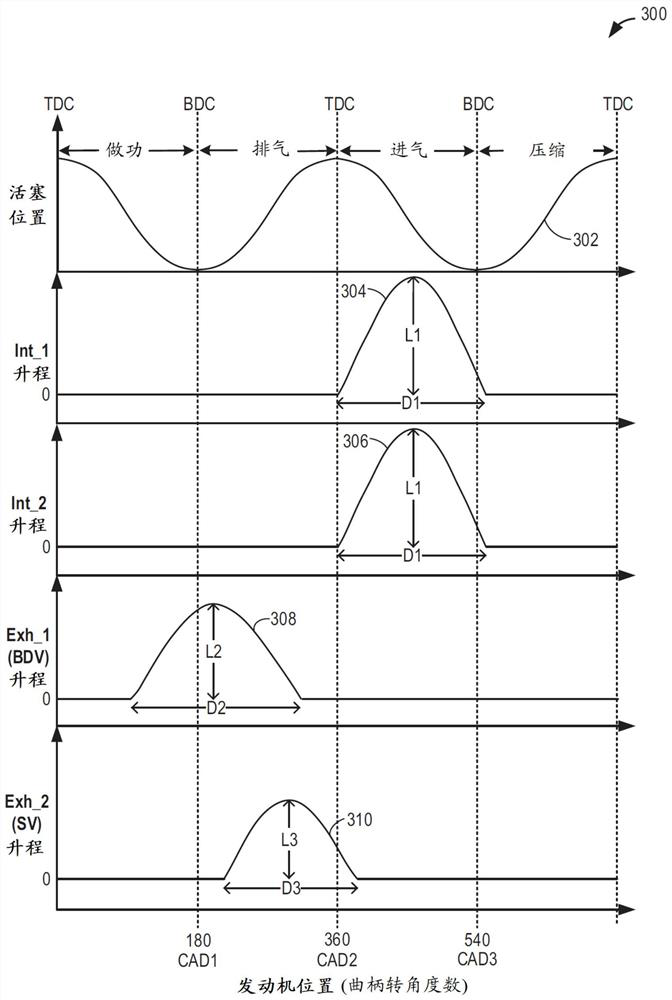

[0016] The following description relates to operating a split exhaust engine with blowing and exhaust gas recirculation (EGR) via a scavenging exhaust manifold to the intake and adjusting direct injection connected short-circuited via said scavenging manifold Systems and methods for an amount of fuel. Such as figure 1 As shown in , the split exhaust engine includes a first exhaust manifold (herein referred to as the blowdown manifold) coupled exclusively to the blown exhaust valve of each cylinder, and a A second exhaust manifold for scavenging the exhaust valves (referred to herein as a scavenging manifold). The scavenging manifold is coupled to the intake passage upstream of the turbocharger compressor via an EGR passage. In some embodiments, the split-exhaust engine system may include couplings such as figure 1 Additional channels between the scavenging manifold and the intake or exhaust channels shown in . Additionally, in some embodiments, split exhaust engine systems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com