A kind of moisture-conducting and quick-drying composite yarn, its preparation method and fabric

A wet and quick-drying, yarn technology, applied in the field of apparel fabrics, can solve the problems of fabric touch, affect fabric comfort, not washable, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

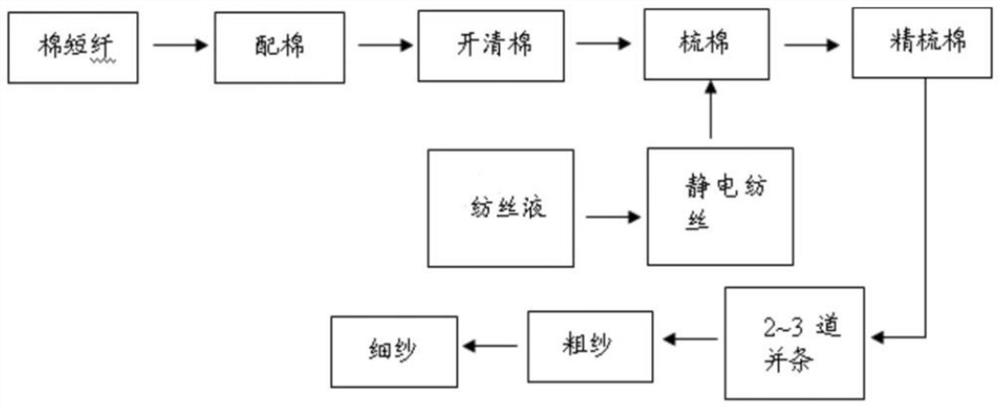

[0029] Correspondingly, an embodiment of the present invention provides a method for preparing a moisture-permeable and quick-drying composite yarn, comprising the following steps:

[0030] S1, the raw cotton staple fiber is subjected to the cotton opening and cleaning process to make cotton bundles;

[0031] mixing and dissolving cellulose acetate powder and acrylic acid powder in a solvent to obtain a spinning solution; the solvent is one or more of acetone and N,N-dimethylacetamide;

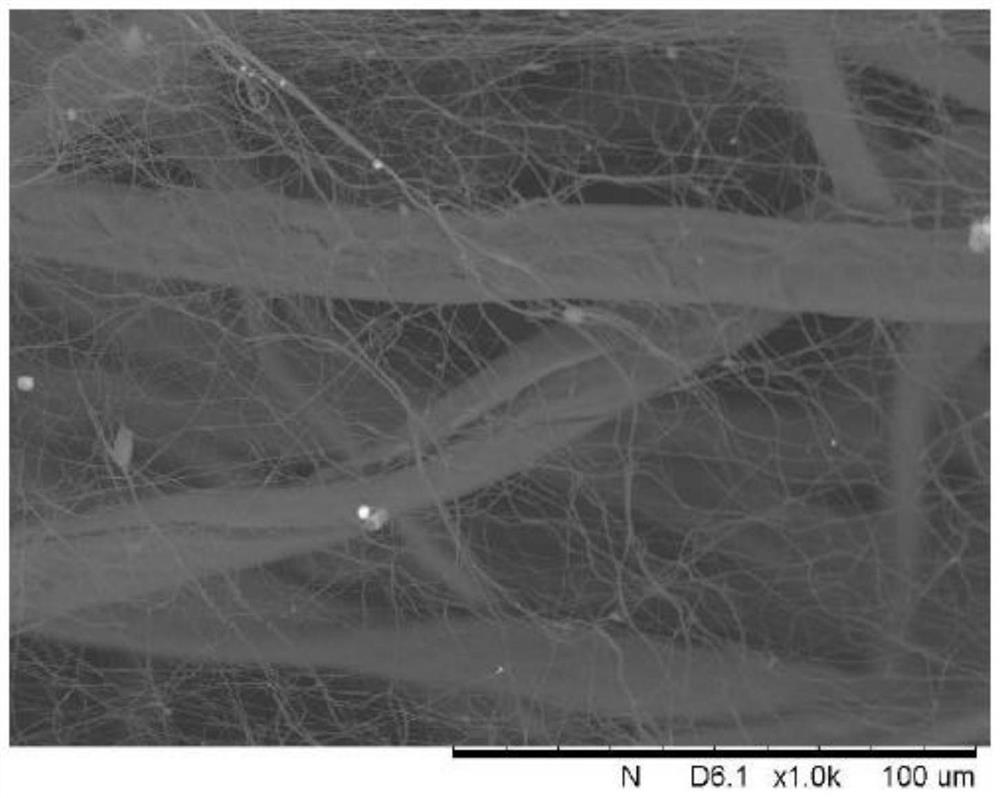

[0032] S2. Carding the cotton bundles obtained in step S1, during the process of carding to form a cotton web, electrospinning the spinning solution, so that the formed micro-nano fibers are combined with the cotton web to make a composite sliver ; The mass percentage of the micro-nano fiber in the composite sliver is 8-10%;

[0033] S3. The composite sliver obtained in step S2 is sequentially combed, drawn, roved and spun to obtain a moisture-conducting and quick-drying composite yarn.

[0...

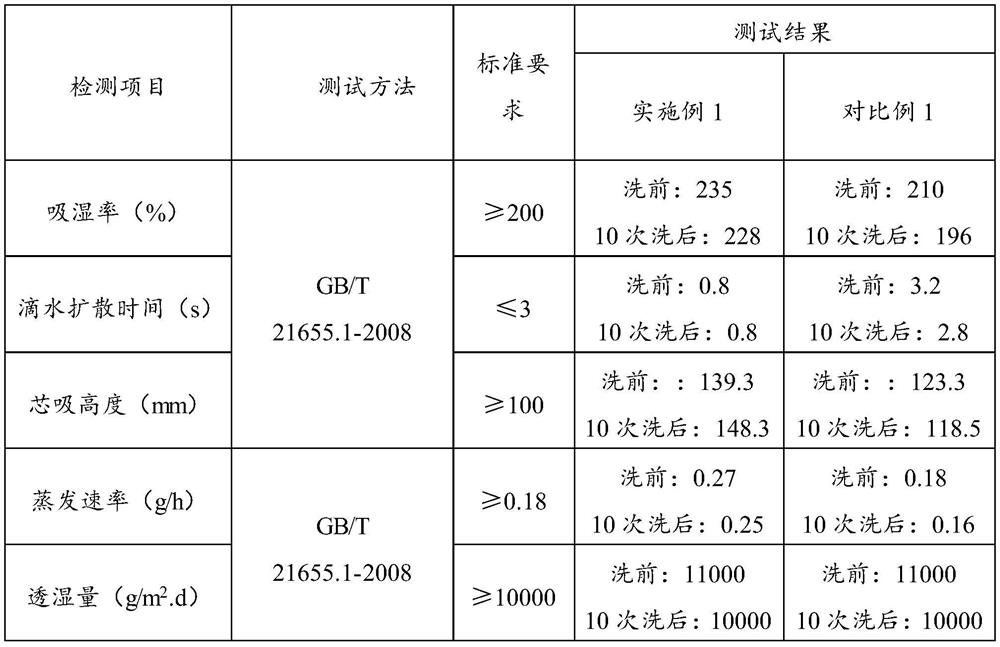

Embodiment 1

[0053] The production method of a moisture-conducting and quick-drying knitted fabric described in this embodiment is as follows:

[0054] (1) Mix the raw cotton staple fiber with cotton, and then perform the cotton opening and cleaning process to make a uniform cotton lap. After opening and cleaning, the impurity content of the laps is controlled below 1%, and the unevenness of the laps is controlled below 1%.

[0055] (2) cellulose acetate (CA-398-3 produced by American Eastman Company, acetylation degree 39.8%, average molecular weight 35000) is dissolved in a solvent, and stirred at room temperature to obtain a cellulose acetate solution; wherein, the solvent is Acetone / N, N-dimethylacetamide (volume ratio 2:1); During the stirring process, add acrylic acid powder to the cellulose acetate solution, the mass ratio of acrylic acid / cellulose acetate is 10 / 90, in Stir and dissolve at 40°C, the stirring speed is 2000r / h, and the stirring time is 10h to obtain a spinning soluti...

Embodiment 2

[0079] The production method of a moisture-conducting and quick-drying knitted fabric described in this embodiment is as follows:

[0080] (1) Mix the raw cotton staple fiber with cotton, and then perform the cotton opening and cleaning process to make a uniform cotton lap. After opening and cleaning, the impurity content of the laps is controlled below 1%, and the unevenness of the laps is controlled below 1%.

[0081] (2) Dissolving cellulose acetate (CA-398-10 produced by American Eastman Company, acetylation degree 39.8%, average molecular weight 40000) in N, N-dimethylformamide, stirred at room temperature to obtain acetic acid Cellulose solution; during the stirring process, add acrylic acid powder to the cellulose acetate solution, the mass ratio of acrylic acid / cellulose acetate is 15 / 85, stir and dissolve at 40°C, the stirring speed is 2000r / h, the stirring time 10h to obtain a spinning solution; the mass concentration of the spinning solution is 14wt%, the surface t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com