Fluctuation type power input water electrolysis hydrogen production method and device

A technology of electrolysis of water and power, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve problems such as poor adaptability, achieve fast cold start speed, increase cold start speed, and ensure production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a method for producing hydrogen by electrolyzing water with fluctuating power input, which specifically includes the following steps:

[0059] Adjusting fluctuating power steps: When the fluctuating input power is not greater than the maximum power required by the electrolyzer, the input power is connected to the electrolyzer to participate in the electrolysis of deionized water;

[0060] When the fluctuating input power is greater than the maximum power required by the electrolyzer, the part equal to the maximum power required by the electrolyzer is connected to the electrolyzer to participate in the electrolysis of deionized water, which is set as the first priority; the excess part is connected to the thermal storage module , set it as the second priority, convert it into thermal energy in the heat storage module and store it in the heat storage module; the fluctuating power is provided by the fluctuating electric energy output module, specifi...

Embodiment 2

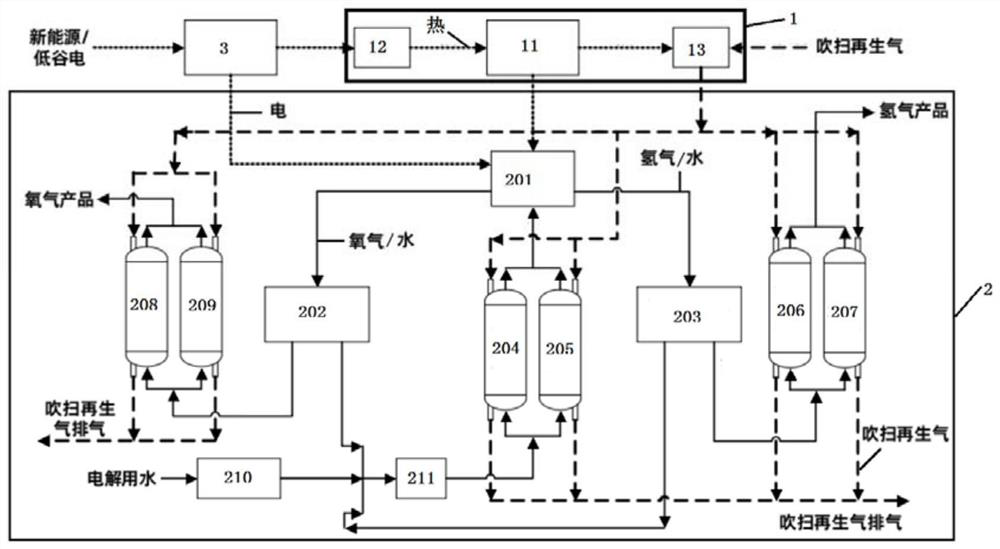

[0068] Such as figure 1 As shown, this embodiment provides a fluctuating power input electrolyzed water hydrogen production device, including a power adjustment module, a heat storage module 1 and a hydrogen production module 2;

[0069] The power adjustment module can be a power adjustment switch 3, such as figure 2 As shown, it includes a power sensor 32, an editable logic controller module 31, a first priority switch 33 and a second priority switch; wherein, the editable logic controller module 31 controls the first priority switch 33 and the second priority switch switch, and are respectively connected to the power sensor 32, the first priority switch 33 and the second priority switch; the power sensor 32 is connected to the fluctuating power supply.

[0070] The working principle of the power adjustment switch: Before running, the two priority switches are kept in the off state; the voltage of the same voltage level is applied to the two ends of the thermal storage modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com