Pure polyurethane condom with adhesive layer, and preparation method of pure polyurethane condom

A polyurethane and adhesive layer technology, applied in coatings, male contraceptives, etc., can solve the problem that the strength is difficult to achieve ideal, and achieve the effects of optimized performance, low formula cost, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

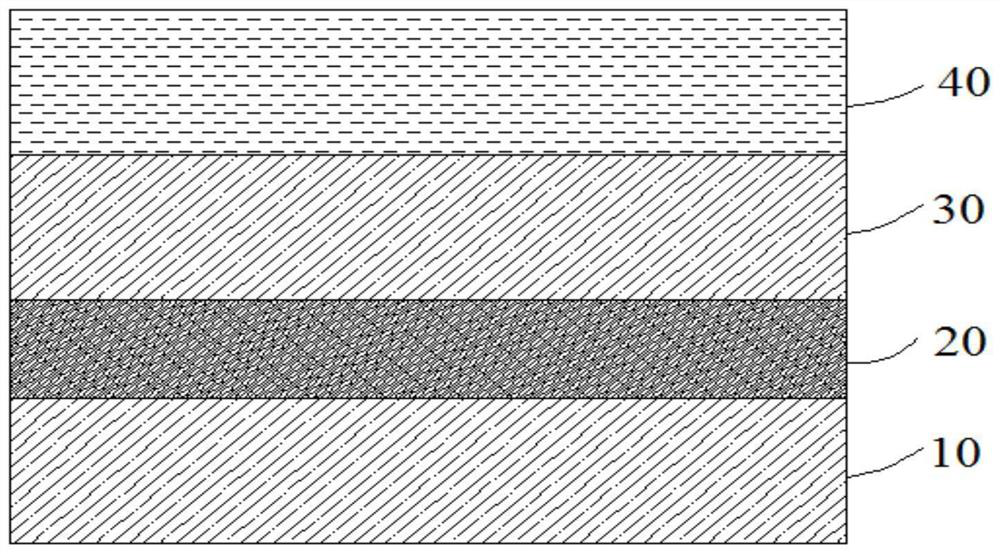

[0047] Such as image 3 As shown, the present invention also discloses another specific embodiment of the polyurethane condom 100 , the polyurethane condom 100 has a first polyurethane film layer 10 , a polyurethane adhesive layer 20 , a second polyurethane film layer 30 , and a third polyurethane film layer 40 .

[0048] Such as image 3 As shown, the first polyurethane film layer 10 , the polyurethane adhesive layer 20 , and the second polyurethane film layer 30 may have the same structure as above, for example.

[0049] Such as image 3 As shown, the third polyurethane film layer 40 is located on the second polyurethane film layer 30, based on obtaining the desired performance of the polyurethane condom 100, the structure of the third polyurethane film layer 40 is consistent with that of the second polyurethane film layer 30 The structure is not the same, for example, the performance is not the same, specifically, for example, the second polyurethane film layer 30 is a hi...

Embodiment 1

[0064] The raw material of described pure polyurethane condom comprises: polyurethane resin N (100% tensile modulus is 1.2N / mm 2 ), high-strength polyurethane resin A (tensile strength is 60MPa).

[0065] Clean the glass mold, heat the mold surface to 30°C, impregnate high-strength polyurethane resin A, and dry at 90°C; impregnate polyurethane resin N, control the thickness to 2 μm, and dry at 80°C; impregnate high-strength type Polyurethane resin A is dried at 100°C; after crimping, the product is dried at 120°C, impregnated with a release agent, and dried at 80°C. After demoulding, conduct electrical inspection, inner packaging, and outer packaging to prepare the ANA structure Layers of polyurethane condom 1.

Embodiment 2

[0067] The raw material of described pure polyurethane condom comprises: polyurethane resin N (100% tensile modulus is 1.0N / mm 2 ), high-strength polyurethane resin A (tensile strength is 60MPa), low-modulus polyurethane resin B (100% tensile modulus is 1.8N / mm 2 ), high elongation polyurethane resin C (elongation at break 700%).

[0068] Clean the glass mold, heat the mold surface to 40°C, impregnate high-strength polyurethane resin A, and dry at 110°C; impregnate polyurethane resin N, control the thickness at 1 μm, and dry at 100°C; impregnate low-modulus Type polyurethane resin B, dried at 110°C; impregnated polyurethane resin N, thickness controlled at 1 μm, dried at 100°C; impregnated with high-extensibility polyurethane resin C, dried at 120°C; after crimping The product is dried at 140°C, impregnated with a release agent, dried at 80°C, and after demoulding, undergoes electrical inspection, internal packaging, and external packaging to prepare a polyurethane condom 2 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com