An arm-type pulling actuator for a radish harvesting robot

A technology of robots and actuators, which is applied in the field of arm-type extraction actuators, can solve problems such as lack of flexibility, and achieve the effects of increasing left and right moving space, enhancing adaptability, and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

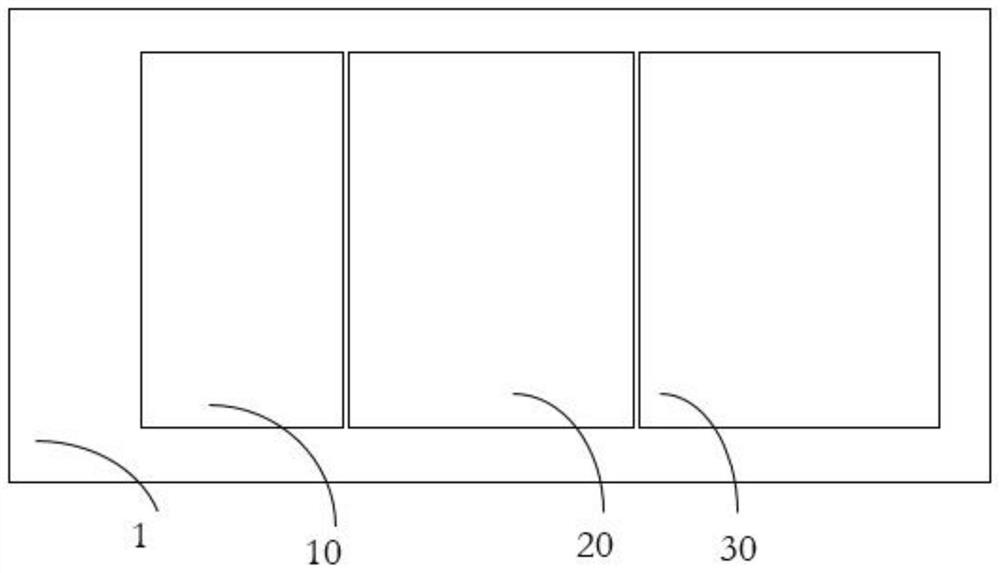

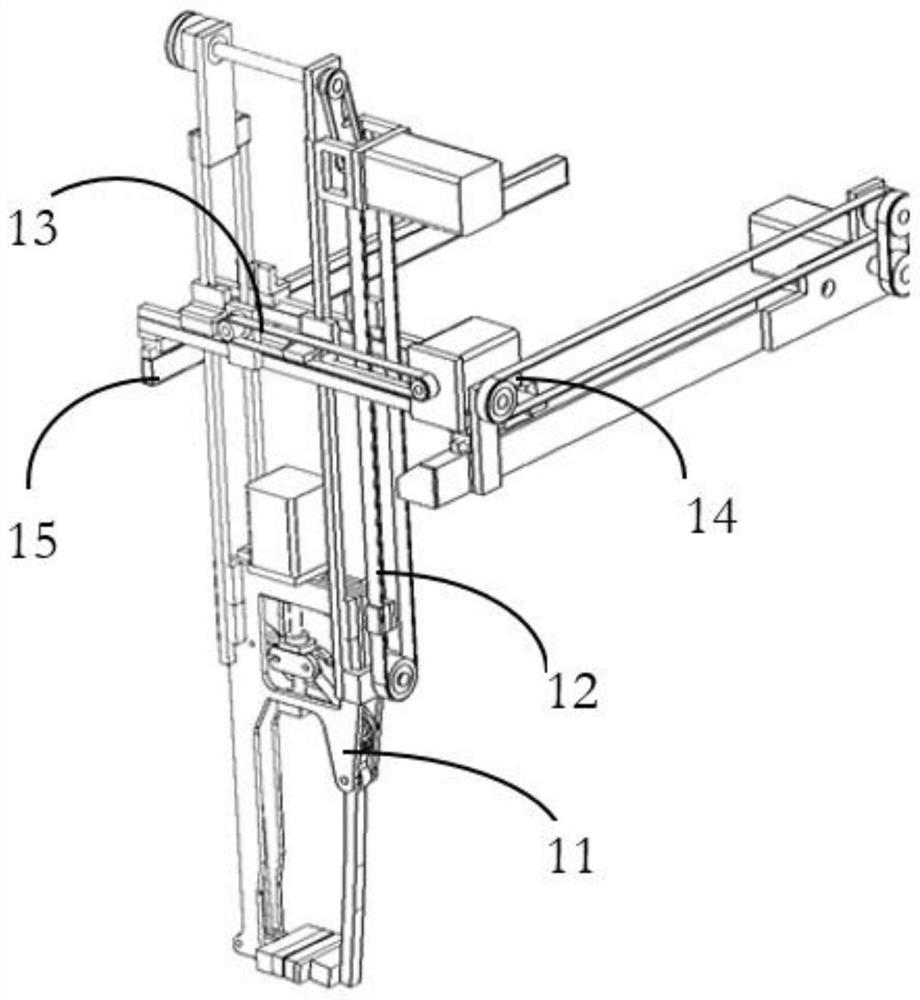

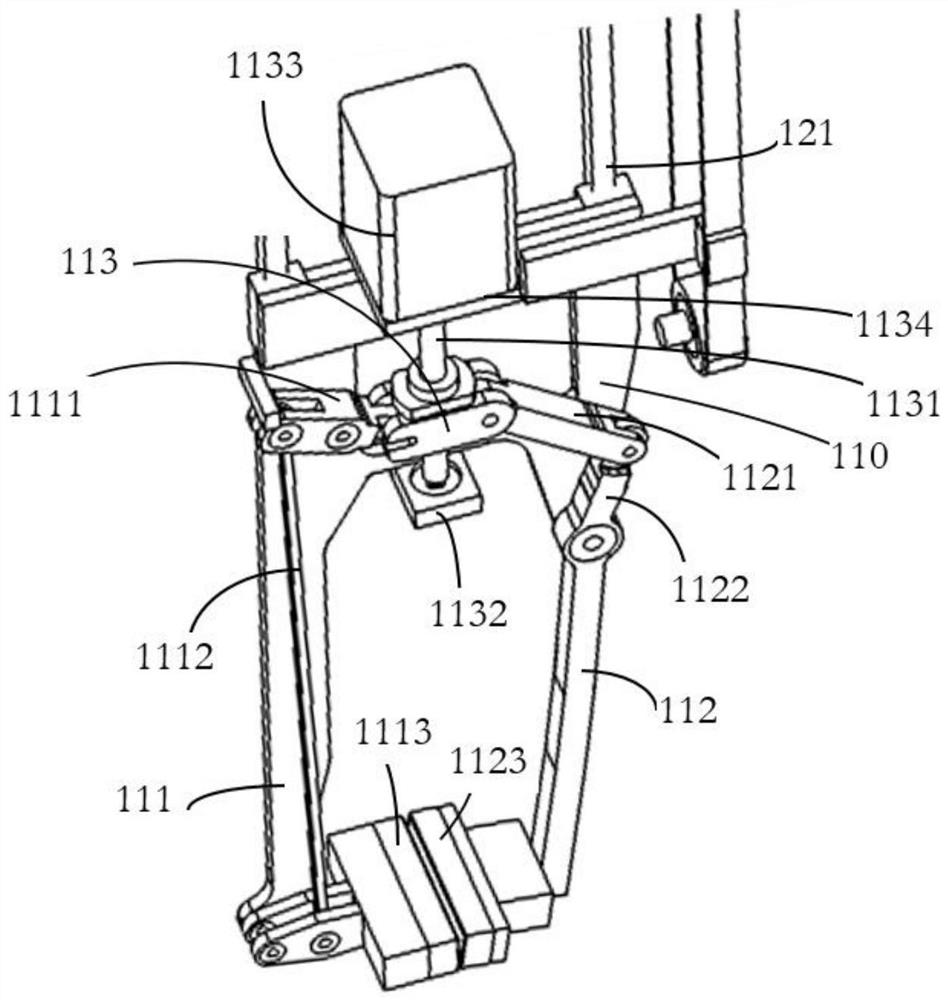

[0024] Such as Figure 1 to Figure 6As shown, this embodiment discloses an arm-type extraction actuator for a radish harvesting robot, which includes an extraction claw 11, a moving arm and a bracket 15; 12. The left and right moving arm 13 and the front and rear moving arm 14, the up and down moving arm 12, the left and right moving arm 13 and the front and rear moving arm 14 respectively control the up and down, left and right, front and back movement of the extracting claw 11; the extracting claw 11 includes a palm 110, the left finger 111, the right finger 112 and the drive mechanism 113, the upper and lower sliding rails 121 and the upper and lower synchronous belts 127 for fixing the two are provided between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com