Micro-channel heat dissipation system and manufacturing method thereof

A technology of a heat dissipation system and a manufacturing method, which is applied in the manufacture of semiconductor/solid state devices, semiconductor/solid state device components, semiconductor devices, etc., can solve the problems of good heat dissipation effect of microchannels and simple manufacturing process, and solve the problem of chip heat dissipation , low cost, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

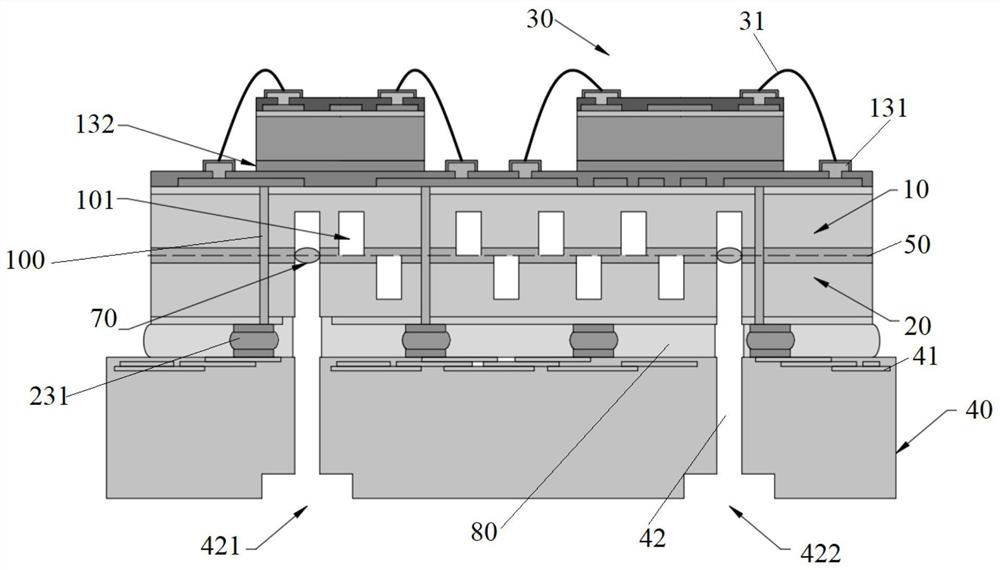

[0065] This embodiment provides a microchannel cooling system, such as figure 1 As shown, the microfluidic heat dissipation system includes sequentially stacked active chips 30, passive components (such as the first passive component 10 and the second passive component 20) and signal interconnection board 40, wherein: the passive The source device includes a first signal interconnection system 100 and a first microchannel heat dissipation system 101; the signal interconnection board 40 includes a second signal interconnection system 41 and a second microchannel heat dissipation system 42; the active The chip 30 has a third signal interconnection system 31; the third signal interconnection system 31, the first signal interconnection system 100 and the second signal interconnection system 41 are electrically connected in sequence; the first microflow The channel cooling system 101 communicates with the second micro-channel cooling system 42 to form a channel for cooling fluid. ...

Embodiment 2

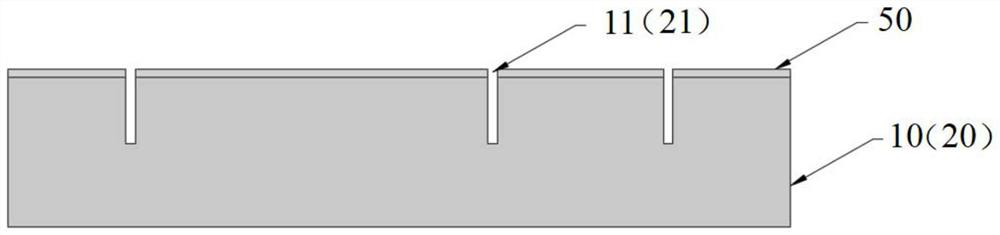

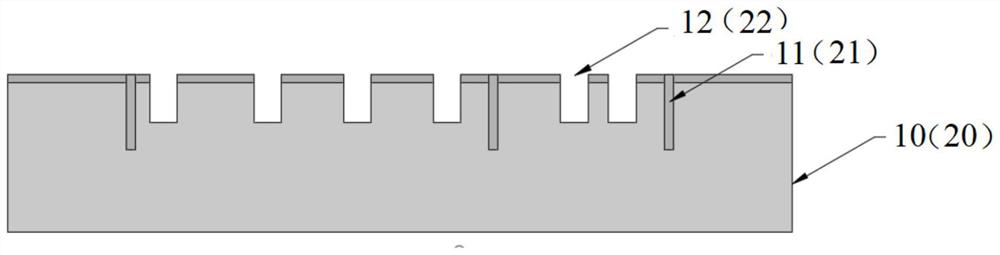

[0072] This embodiment provides a method for manufacturing a microfluidic cooling system, such as Figure 2-12 As shown, the manufacturing method of the micro-channel heat dissipation system includes: forming a first signal interconnection system 100 and a first micro-channel heat dissipation system 101 on at least one passive device; forming a second signal interconnection system 101 on a signal interconnection board 40 Signal interconnection system 41; make the first signal interconnection system 100 electrically connected to the second signal interconnection system 41; connect at least one active chip 30 to the passive device, and the active chip 30 has a third signal interconnection system 31, so that the first signal interconnection system 100 is electrically connected to the third signal interconnection system 31; a second micro-channel cooling system 42 is formed on the signal interconnection board 40; The first micro-channel cooling system 101 communicates with the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com