Semi-analytical method for predicting performance of deep-layer butt-joint buried heat exchanger

A performance prediction and heat exchanger technology, which is applied in the testing of machine/structural components, instruments, measuring devices, etc., can solve problems such as the inability to predict the performance of deep-to-ground buried heat exchangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

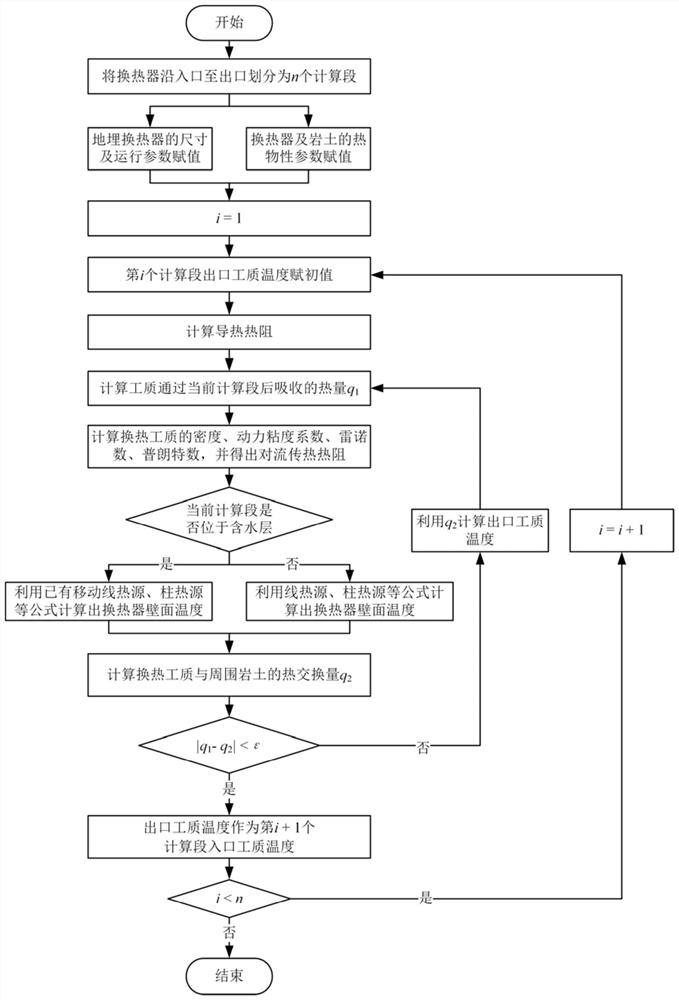

Method used

Image

Examples

Embodiment

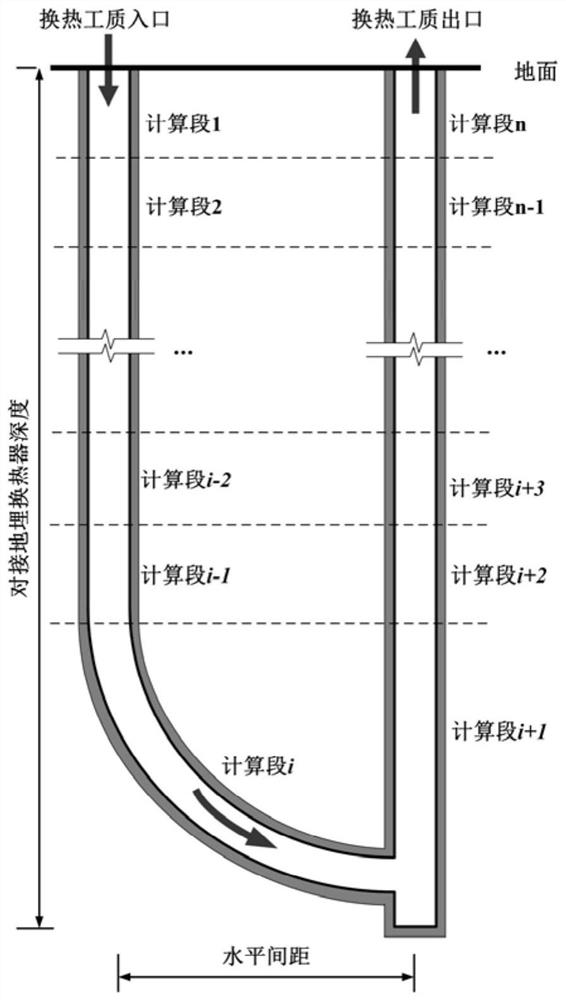

[0098] In order to illustrate the technical solution of the present invention more clearly, the calculation object is a docking heat exchange well with a depth of 2505 meters, a horizontal distance of 200 meters, and a heat exchange medium of water, and an example of running for 1 day (t=86400s) to implement Examples are introduced.

[0099] S100: Calculate the segment division part. The deep-to-ground buried heat exchanger is divided into 51 calculation sections along the flow direction of the working fluid. Among them, the 1st to 25th and 27th to 51st calculation segments are in the vertical direction, and their length is length(i)=100m; the 26th calculation segment is in the horizontal direction, and their length is length(26)=200m.

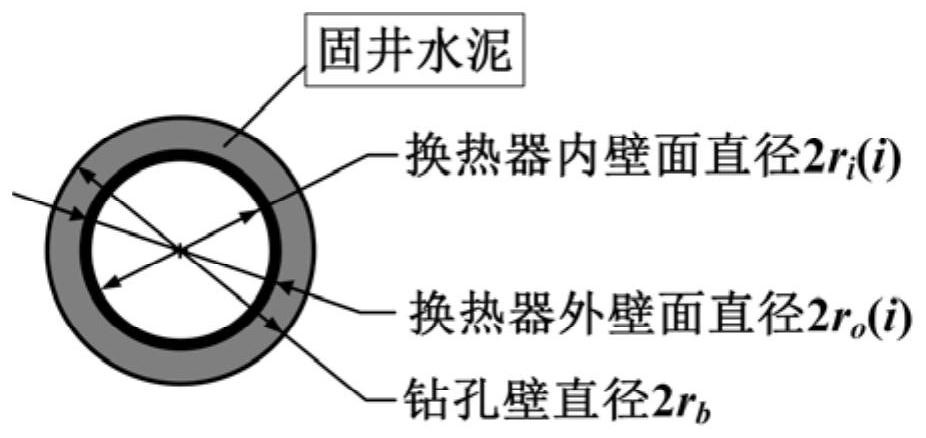

[0100] S200: a parameter assignment part. The structural parameters of the heat exchanger are: outer diameter r o (i) = 0.06985m, inner diameter r i (i) = 0.06068m, drilling diameter r b =0.10795m, heat exchanger inlet temperature T in =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com