Computational fluid dynamics (CFD) technology-based method for optimizing acoustic path of multi-path ultrasonic flowmeter assembled in elbow pipe

An ultrasonic flowmeter, multi-acoustic technology, applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., to achieve the effect of saving experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

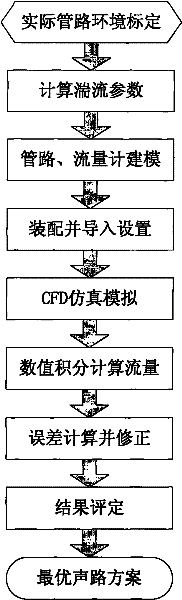

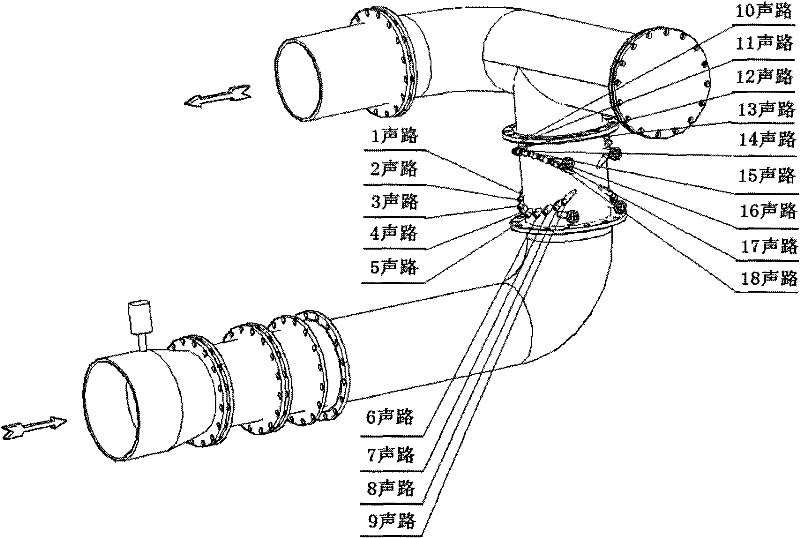

[0026] Below in conjunction with accompanying drawing of description, the present invention is described in conjunction with the simulation optimization example of field experiment, concrete steps are as follows figure 1 Shown:

[0027] 1) According to the data provided by the experimental site, the inner diameter of the pipeline is d=399.489mm, the radius of curvature of the elbow is 440mm, the inlet flow velocity is 0.3m / s~4m / s, the fluid is water, and the ambient temperature is 19.7°; calculated by looking up the table The kinematic viscosity of water at this temperature v=1.007×10-6m2 / s, calculated by the Reynolds number formula It can be seen that the Reynolds number is between 1.19×105-1.59×106; it is calculated by the Dean number formula It can be seen that Dean's number is 1.13×10 5 -1.52×10 6 between; since the test pipelines are all smooth tubes, according to the revised Prandtl smooth tube formula Calculate the drag coefficient λ along the way between 0.013-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com