A construction method for anti-sliding walls of rigid variable cross-section high-pressure rotary grouting piles

A technology of high-pressure rotary grouting piles and construction methods, which can be applied to sheet pile walls, excavation, and foundation structure engineering, etc., and can solve problems affecting the anchorage strength of anchor cables, loss of prestress of anchor cables, and poor anti-sliding effect of sliding zone soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

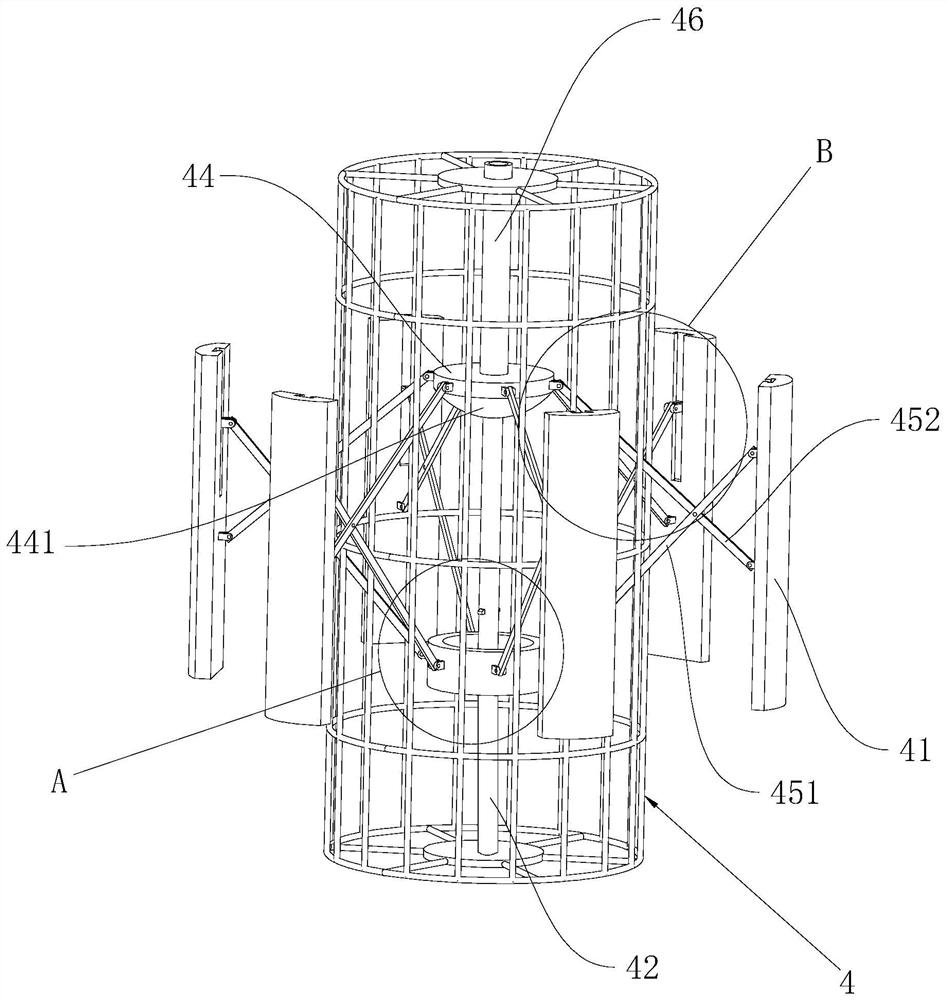

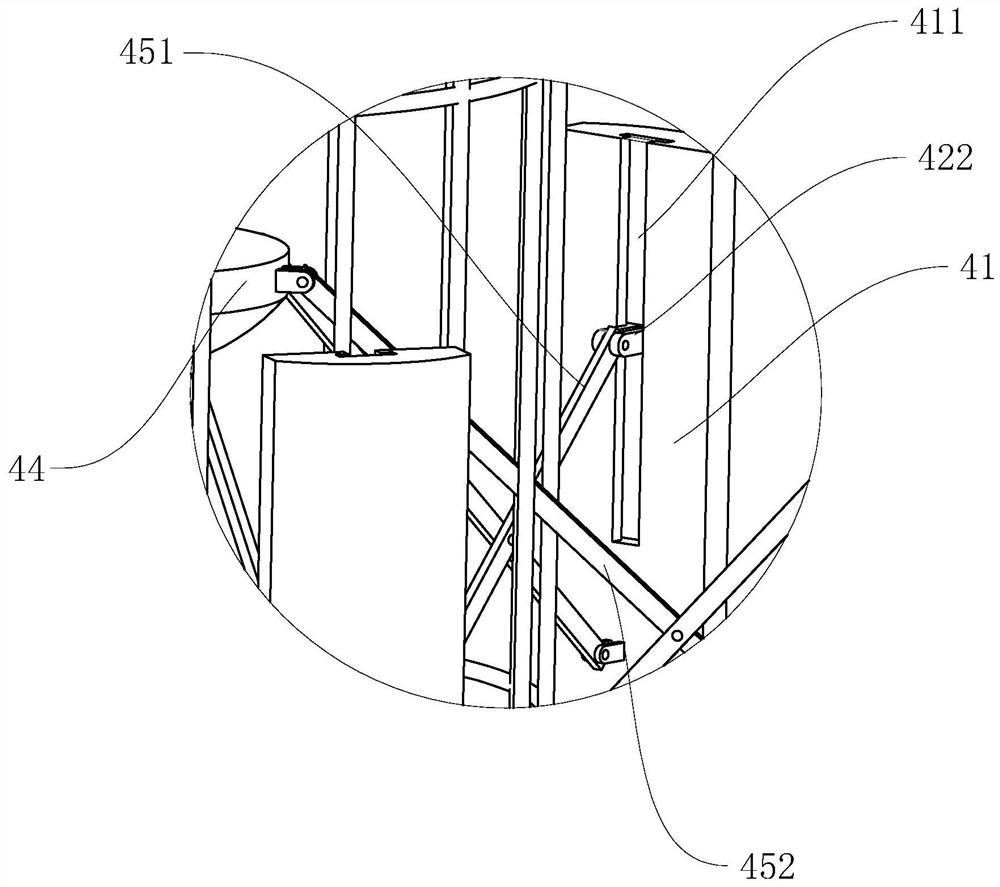

[0037] Conjunction with the drawings of the present invention will be further described in detail.

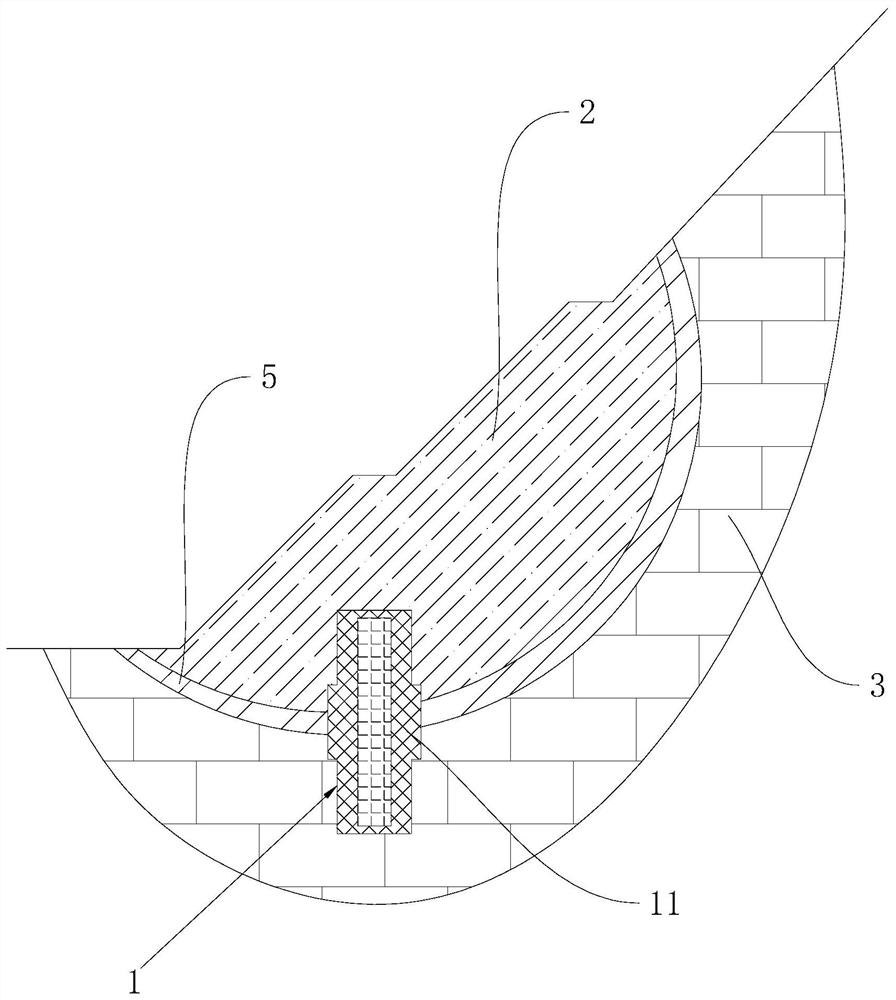

[0038] Refer figure 1 A strength of the present invention disclosed a high pressure rotary sliding Tapered wall jet pile construction method, comprising the steps of:

[0039] Sl, landslide site visits, engineering geological survey and mapping, and analysis to determine the causes of slope stability control factors; 5 determining the position of sliding soil, thickness, and shape of physical and mechanical indicators;

[0040]S2, according to the on-site survey, the slope stability analysis is performed, determine the predetermined spatial position of the anti-slip pile wall, determine the number of anti-slip pile wall and the depth of the buried;

[0041] S3, sliding wall pile, drilling and construction for forming a high pressure spraying pile to a predetermined position, so that the bottom wall of the sliding carriage tape 5 is inserted into the undisturbed soil below the soil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com