O-shaped ring die capable of being positioned

An O-ring and mold technology, applied in the field of molds, can solve the problems affecting the casting process, loosening, unstable positioning, etc., and achieve the effects of not easy to loosen, stable positioning, and not easy to bend and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

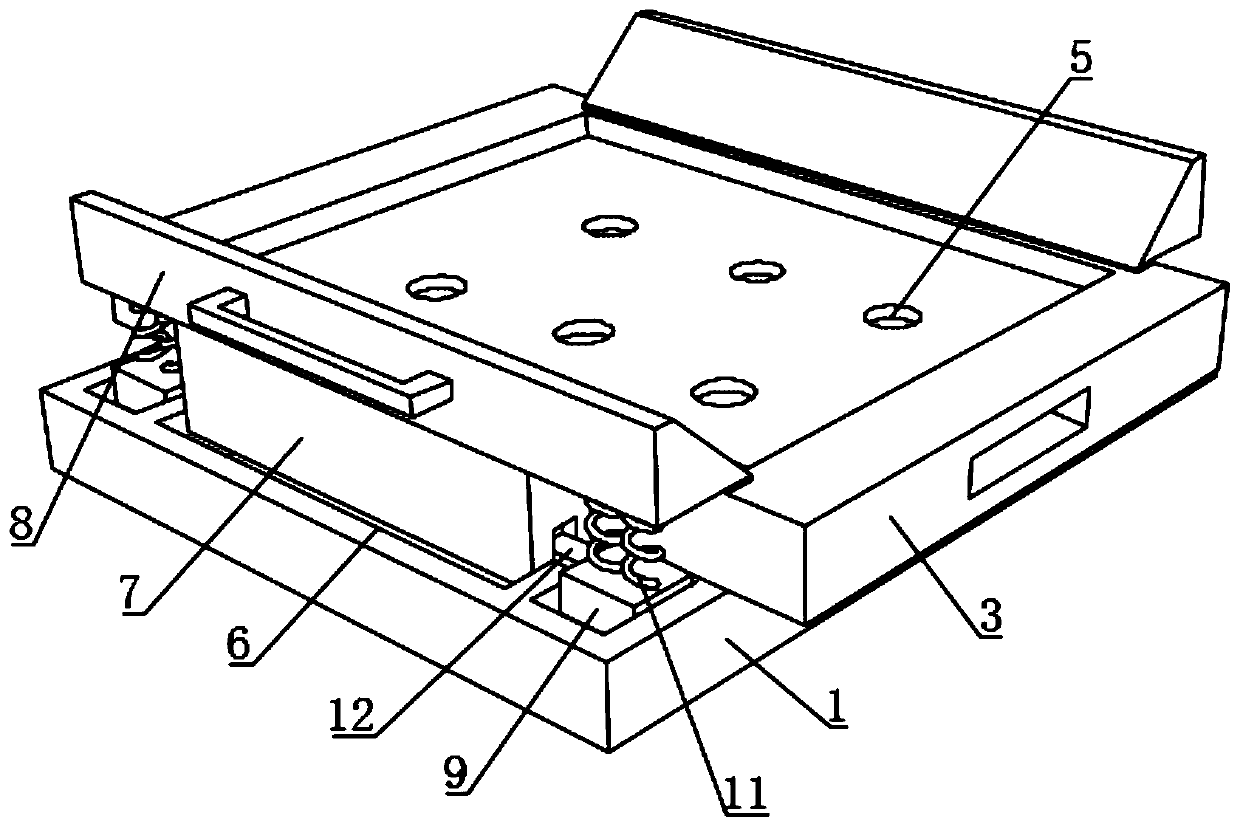

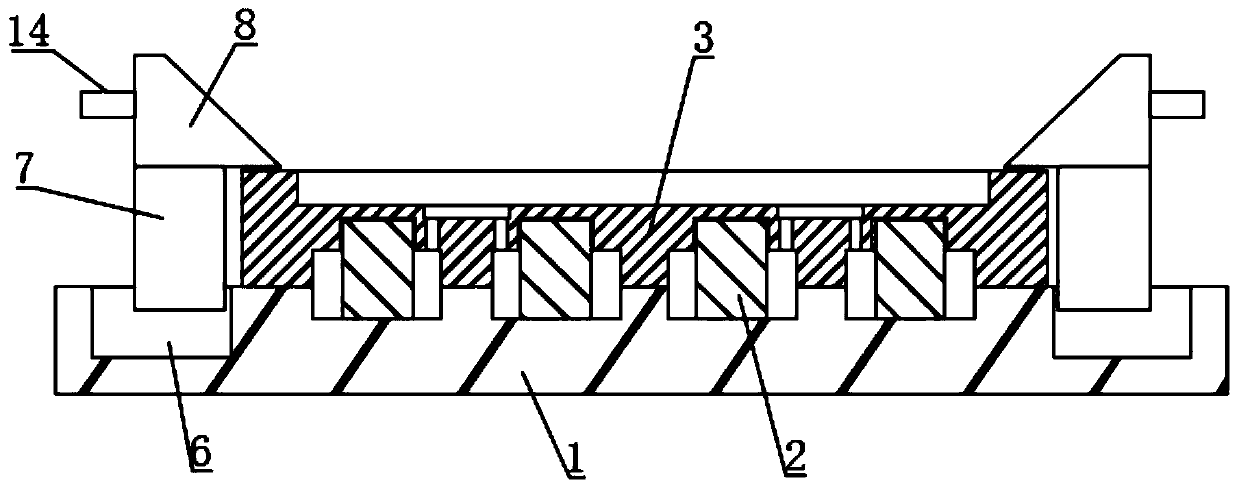

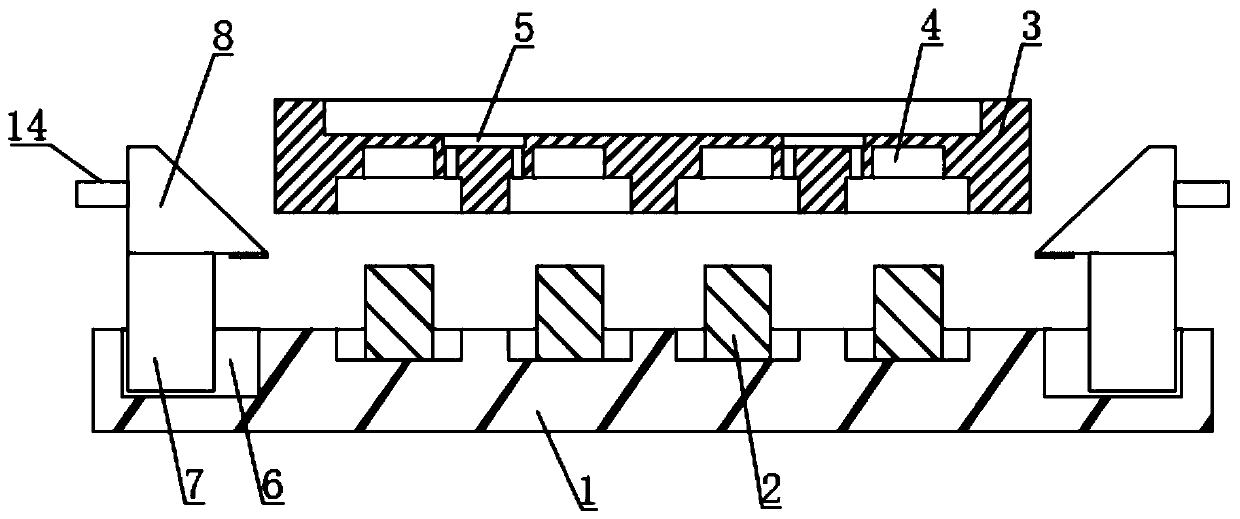

[0034] see figure 1 , a positionable O-ring mold, including a lower film 1 and an upper mold 3 each provided with a plurality of cavities, the upper mold 3 is located on the lower side of the lower film 1, and the upper end of the upper mold 3 is dug with a plurality of casting ports 5, see figure 2 with image 3 , a single casting port 5 is located between a pair of adjacent mold cavities, and a pair of mold cavities communicate with the casting port 5, and the slurry is injected into the closed cavity formed by the lower film 1 and the upper mold 3 through the casting port 5, and the lower A core 2 is provided inside the cavity of the film 1, and a limiting groove 4 is dug on the top surface of the cavity of the upper mold 3, and the core 2 matches the limiting groove 4. Compared with the prior art, four guide pillars are used to carry out In the way of positioning, the present invention can make the positioning of the lower film 1 and the upper mold 3 more accurate and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com