Lower die underframe assembly and hot-pressing lower die structure

A component and mold bottom technology, which is applied in textiles and papermaking, etc., can solve the problems of inconvenient maintenance and repair, troublesome processing and manufacturing, and difficult to guarantee high-precision coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

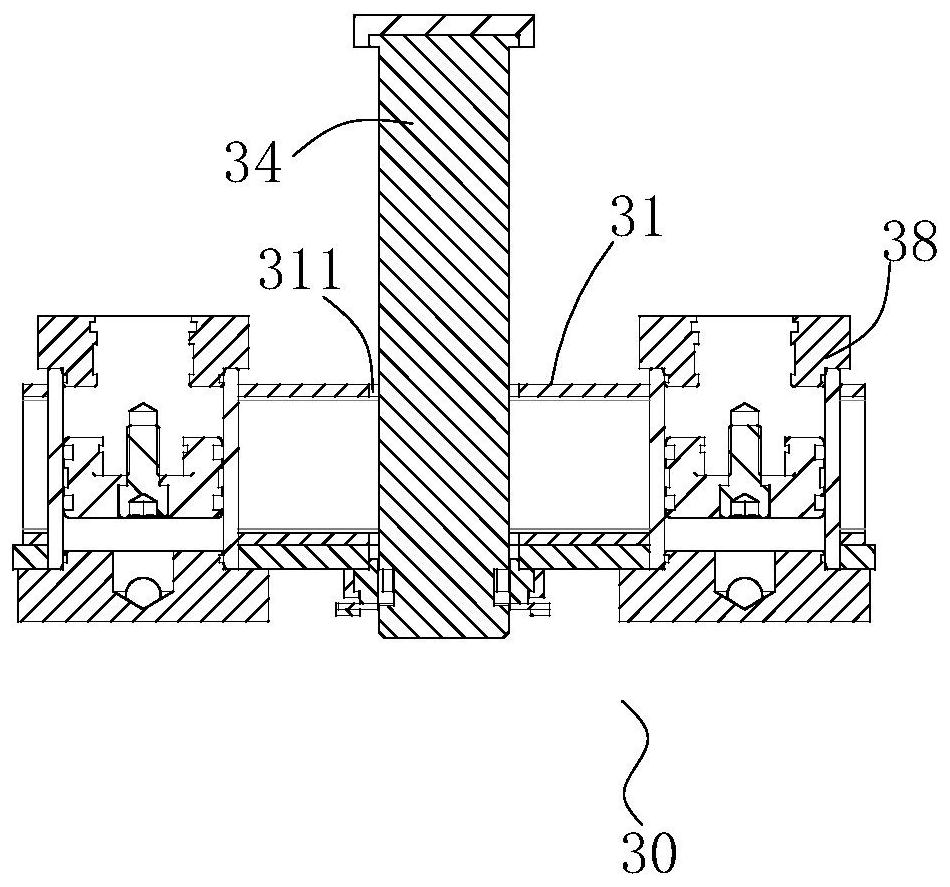

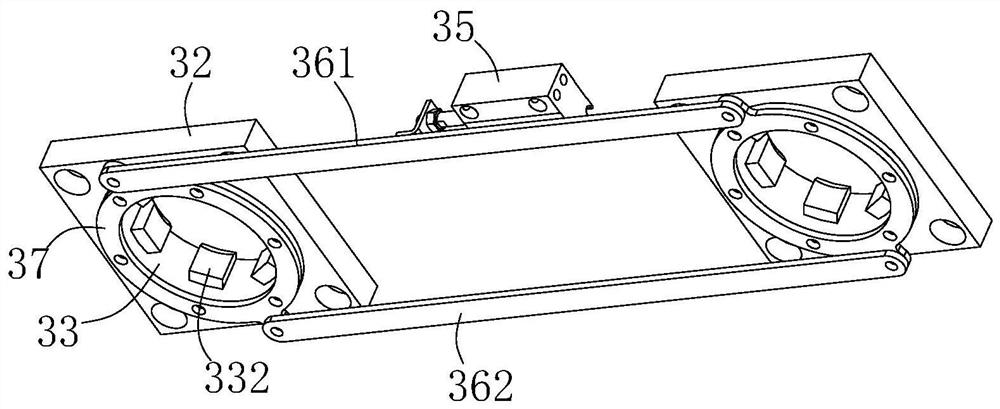

[0054] Please refer to Figure 1-4 , this embodiment provides a lower mold chassis assembly 30, including:

[0055] The chassis main body 31, the bottom chassis main body 31 is formed with a connecting shaft penetration hole 311 passing through its top surface and bottom surface;

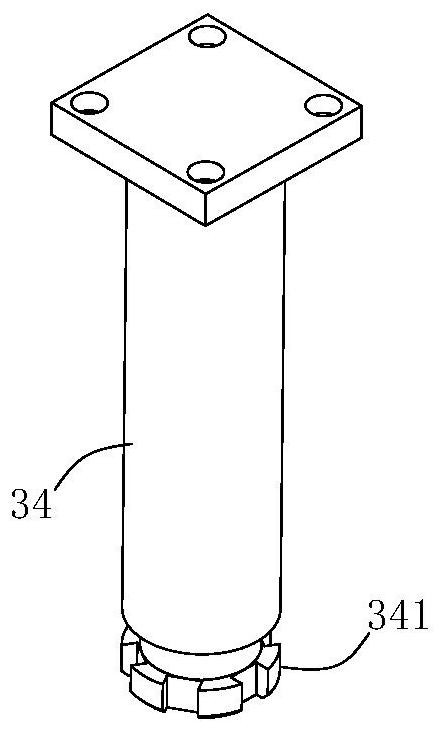

[0056] Locking mechanism, the locking mechanism comprises axle sleeve installation plate 32, rotating axle sleeve 33 and connecting shaft 34; The insertion hole 321 connected with the insertion hole 311; the rotating sleeve 33 is rotatably mounted on the sleeve installation plate 32, and the rotating sleeve 33 has a central through hole communicated with the insertion hole 321 arranged along its axial direction 331, a plurality of first splines 332 are arranged at intervals in the circumferential direction of the central through hole 331 of the rotating shaft sleeve 33; the connecting shaft 34 is arranged directly above the chassis main body 31, and its lower end is facing the connecting shaft inse...

Embodiment 2

[0061] refer to Figure 1-15 , this embodiment provides a hot pressing lower die structure, including: a hot pressing lower die assembly 10, a lower die mounting substrate 20, a lower die chassis assembly 30 of Embodiment 1, a guide post 40 and a lifting cylinder 50;

[0062] The lower die mounting base plate 20 is located below the hot pressing lower die assembly 10, and the lower die mounting base plate 20 is provided with a piston rod penetration hole 21;

[0063] The lower mold chassis assembly 30 is located below the lower mold mounting substrate 20; the upper end of the connecting shaft 34 is fixedly connected to the bottom surface of the lower mold mounting substrate 20;

[0064] The upper end of the guide post 40 is fixedly connected to the hot pressing lower die assembly 10 through the lower die mounting substrate 20 , and the lower end thereof is fixedly connected to the lower die chassis assembly 30 ;

[0065] The cylinder body of the lifting cylinder 50 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com