Anti-aging functionalized montmorillonite modified asphalt and preparation method thereof

An anti-aging and functional technology, applied in building components, building insulation materials, construction, etc., can solve the problems of less modified asphalt application research and achieve the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Disperse 1 part of dry montmorillonite in 200 parts of deionized water, and stir at 1200 r / min for 1 h. The preparation method of the Tris-HCl buffer solution is to add 2.484g of Tris into 200ml of deionized water, and adjust the pH value of the solution to 8-9 with hydrochloric acid. Take 0.5 parts of dopamine and add it into the prepared Tris-HCl buffer solution to adjust the pH value of the solution to 8-9. Quickly add the montmorillonite suspension to the dopamine solution, the stirring speed is 800r / min, and the stirring time is 2h. After stirring at a high speed, the precipitate is washed and fully dried at 90-120°C to obtain the mass ratio of montmorillonite: dopamine 2:1 PMMT 1 .

Embodiment 2

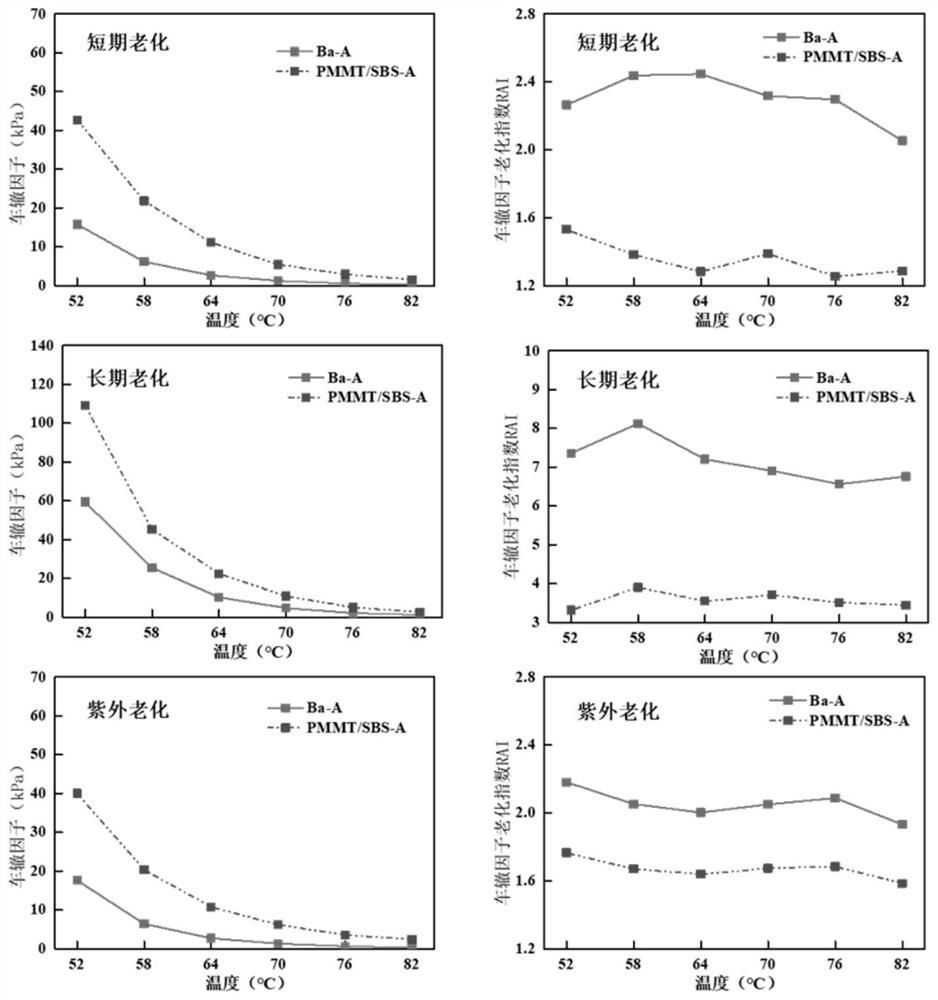

[0039] Obtain PMMT through embodiment 1 1 . The PMMT obtained by melting 1 For the modification of asphalt, take 100 parts of asphalt and pour it into the reaction vessel of the heating mantle, heat it to about 145 ° C ~ 160 ° C, and then add 4 parts of PMMT 1 Add it to the molten asphalt in several times, and shear it for 40min at a shear rate of 4000r / min, so that PMMT 1 Fully dispersed in molten asphalt. Add 4.5 parts of SBS to the asphalt in several times, and shear at a shear rate of 4000r / min for 80min. Then develop for 60min at a stirring speed of 600r / min to obtain aging-resistant PMMT / SBS-A. According to the national standard JTG E20-2011 "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", PMMT / SBS-A were subjected to short-term aging for 85 minutes, long-term aging for 20 hours under 2.1MPa±0.1MPa air pressure and light intensity 15mW / cm 2 Under UV aging for 120h.

[0040] The influence of PMMT on the anti-aging performance of asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com