Unmanned bridge crane control system

A technology of control system and general control system, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problem of lack of accurate operation site and slag bag data, dynamic monitoring and material information tracking, slag bag Information about lifting equipment status and water-cooling equipment parameters cannot be transmitted in a timely and accurate manner, so as to reduce man-made failures and industrial accidents, facilitate command scheduling and exhibition visits, and meet the needs of intelligent production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. The following description of at least one exemplary embodiment is merely illustrative in nature and not intended as any limitation of the invention, its application or uses. Based on the embodiments of the present invention, other embodiments obtained by persons of ordinary skill in the art without carrying out creative work all belong to the protection scope of the present invention.

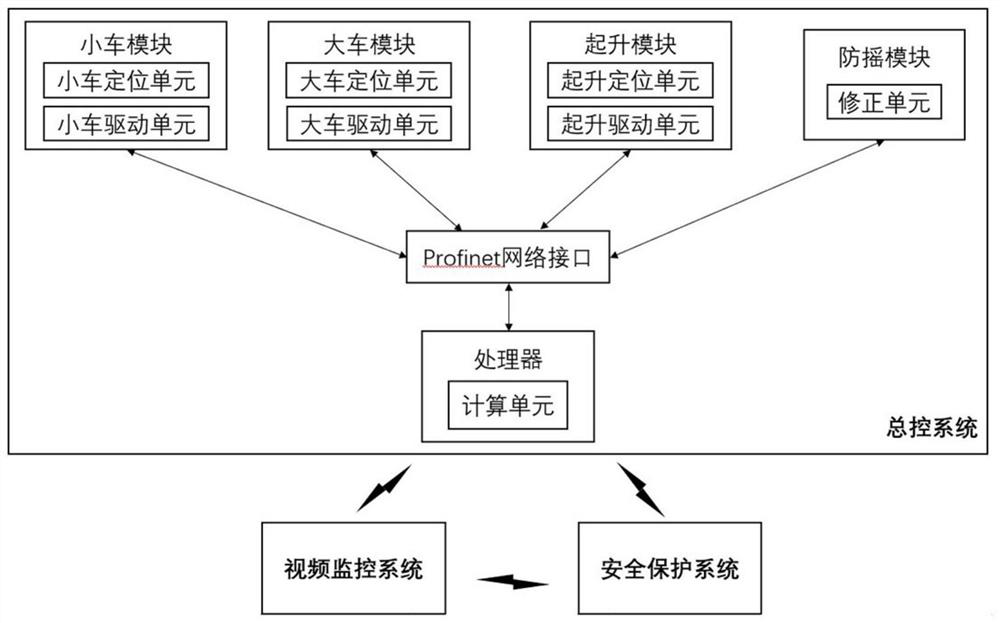

[0023] figure 1 Shown is the system structure block diagram of the present invention. An unmanned crane control system provided by the present invention includes a general control system, a video monitoring system and a safety protection system, and wireless communication is ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com