Extruder waste heat recycling device based on energy-saving technology

A technology of extruder and thermal cycle, which is applied in the field of extruder waste heat recycling device based on energy-saving technology, can solve the problems of difficult heat utilization and poor heat utilization rate, and achieve the effect of avoiding heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

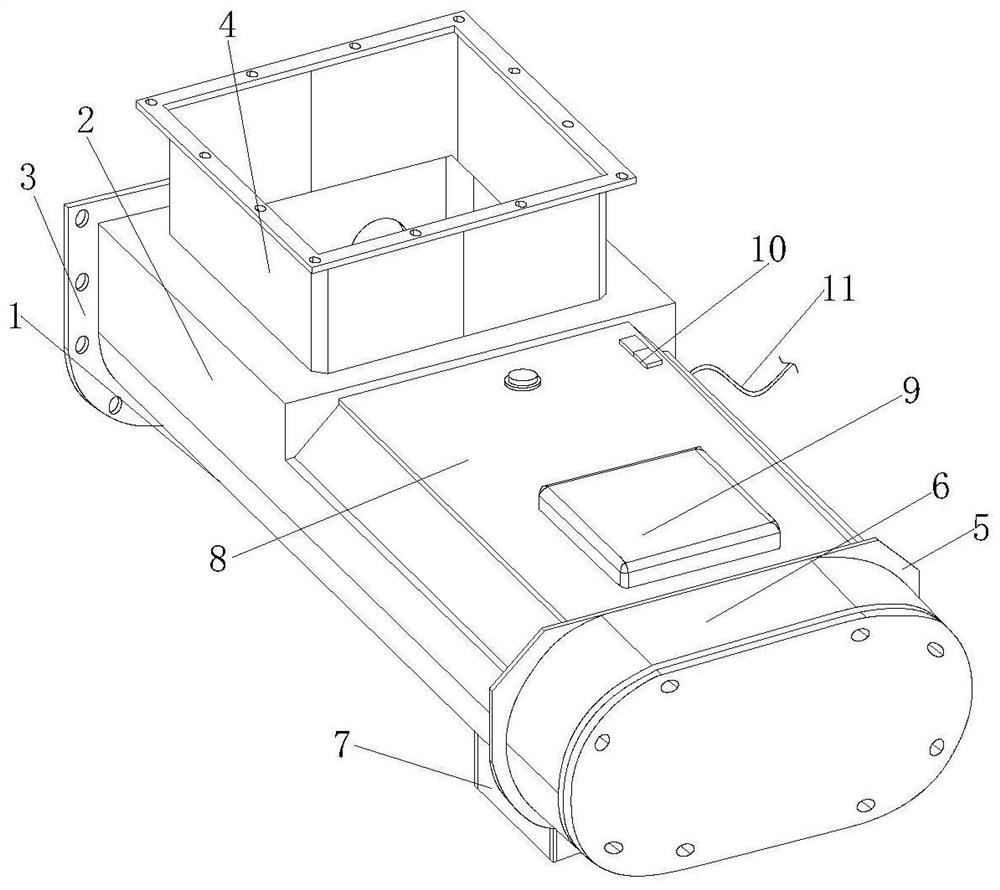

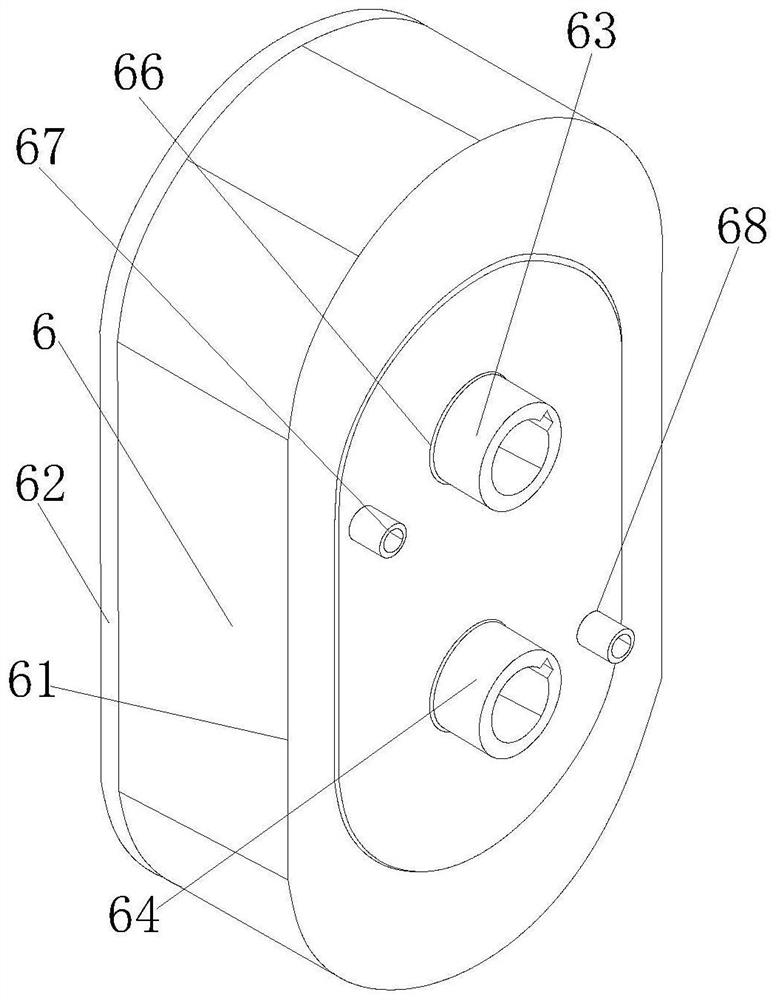

[0030] see figure 1 , an extruder waste heat recycling device based on energy-saving technology of the present invention, the heat cycle main body 1 includes a frame seat 2, a connecting flange piece 3, a feeding frame 4, a connecting piece 5, a transmission mechanism 6, and a discharging frame 7 , a processing chamber 8, a top cover 9, a control switch 10 and a power cord 11, the left end of the frame base 2 is welded and fixed with a connecting flange piece 3, the top left side of the frame base 2 is integrally formed with a feed frame 4, and the frame base 2. The right end surface is fixed with the transmission mechanism 6 through the connecting piece 5. The discharge frame 7 is integrally formed on the right side of the bottom of the frame base 2. The right side of the frame base 2 is embedded with a processing chamber 8, and the right side of the top of the processing chamber 8 is plugged in. A top cover 9 is fixed, a control switch 10 is provided on the top left side of ...

Embodiment 2

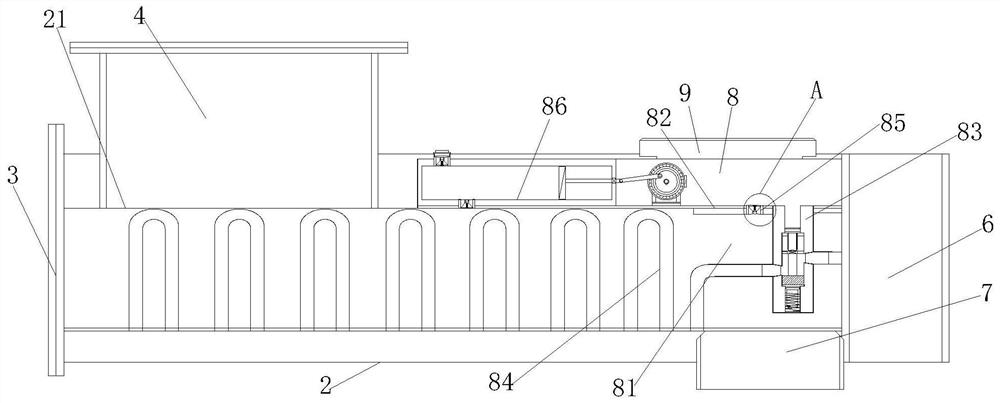

[0037] In an extruder waste heat recycling device based on energy-saving technology of the present invention, a feeding tube 21 is embedded in the middle side of the frame seat 2, and the left side of the top of the feeding tube 21 is connected with the feeding frame 4, and the feeding tube 21 The right side of the bottom is connected with the discharge frame 7, and the extruding work is carried out inside the feeding tube 21. When the bolt rod 839 is located on the top side inside the barrel seat 831, the right side of the clamping block 836 fits inside the inlet pipe 833, so that The inlet pipe 833 is closed to block the internal passage. The valve body 85, the lower valve seat 867 and the upper valve seat 868 have the same structure. The flow direction of the gas inside the valve body 85 is from outside to inside, and the flow direction of the gas inside the lower valve seat 867 is From bottom to top, the flow direction of gas inside the upper valve seat 868 is from bottom t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com