Hydraulic dual-station clamp and working method thereof

A double-station, fixture technology, applied in the field of hydraulic fixtures, can solve the problems of low work efficiency of fixtures, inconvenient adjustment of fixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

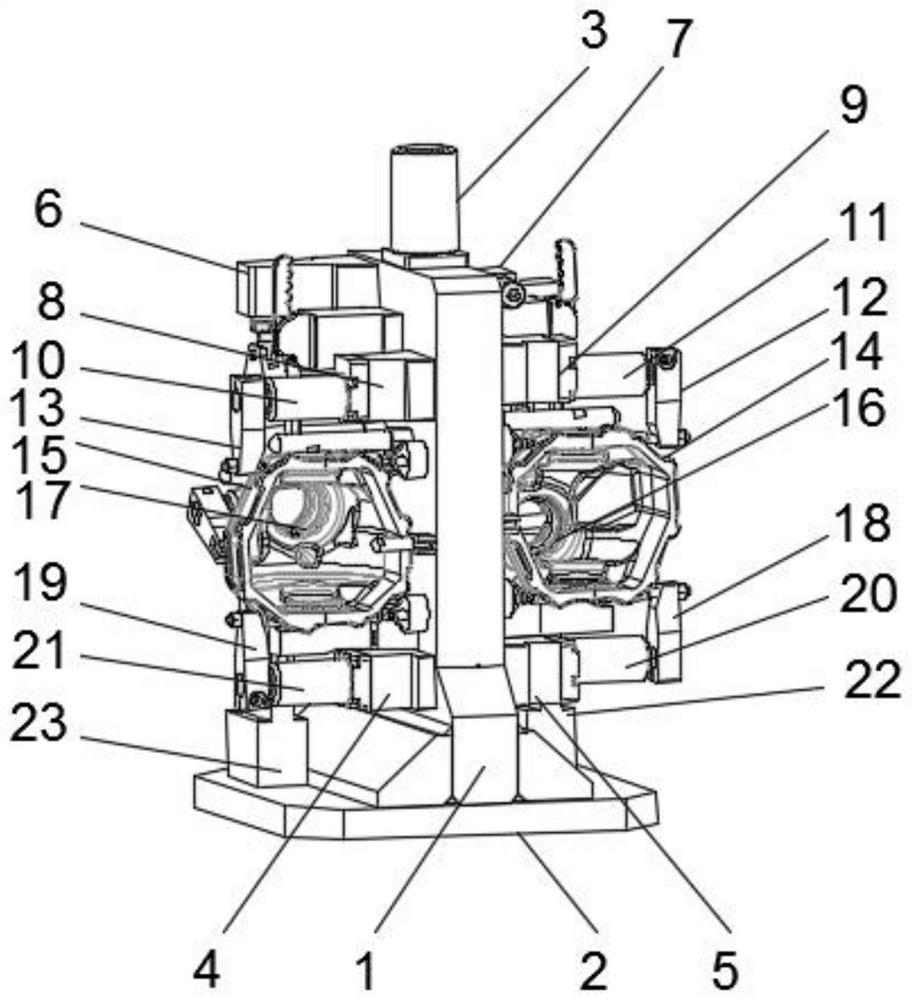

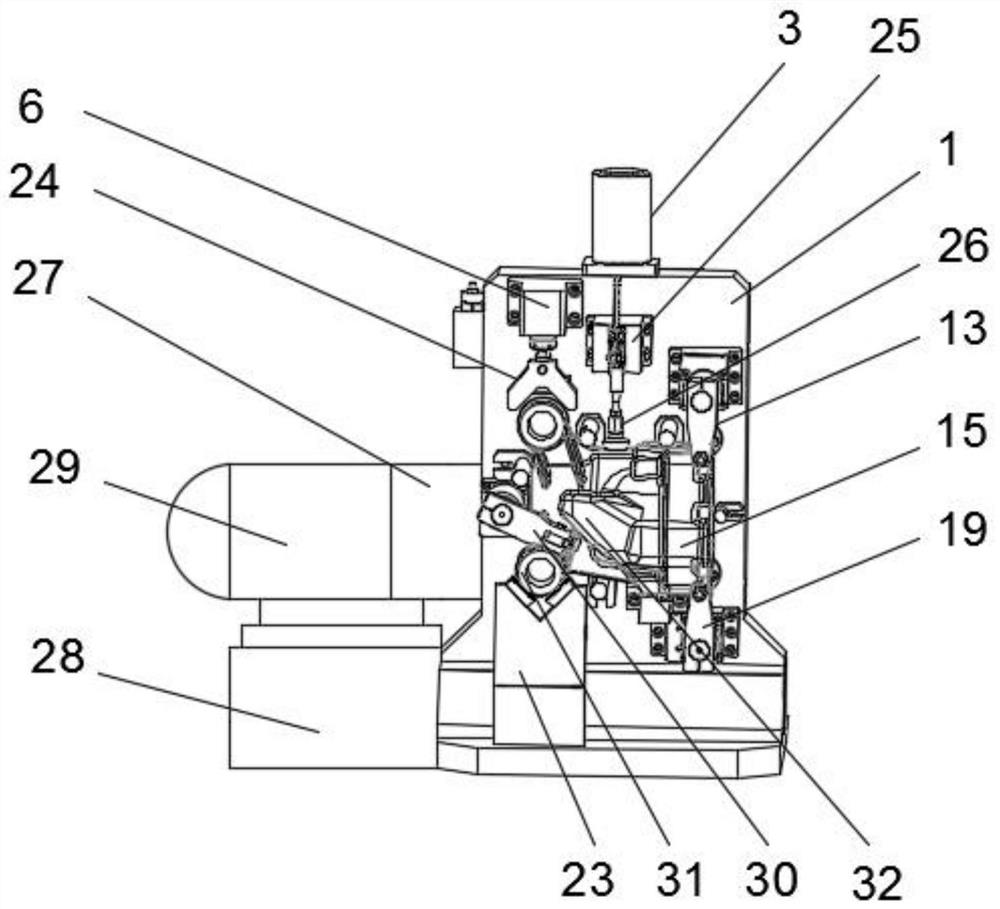

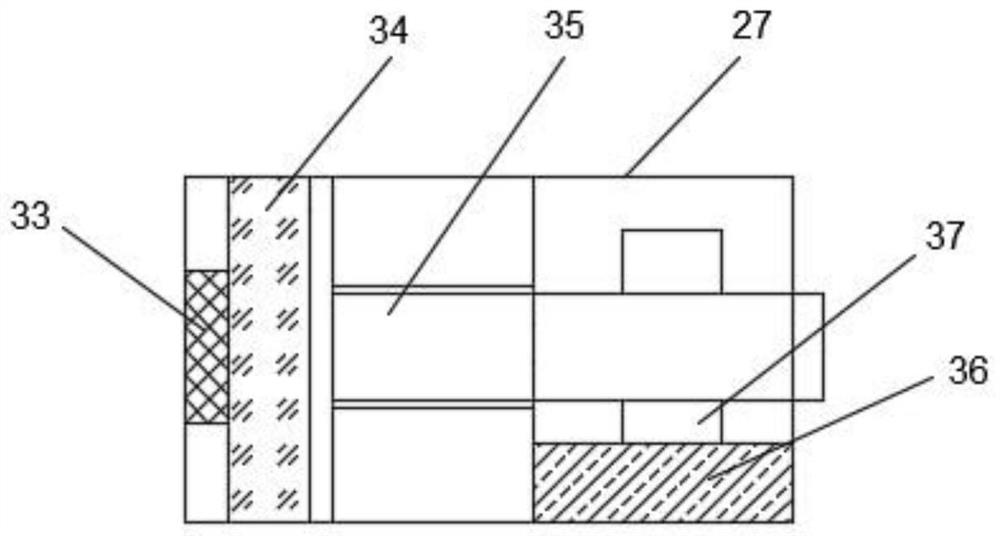

[0033] Such as Figure 1-4 As shown, a hydraulic double-station clamp includes a support plate 1, a first clamp body 14 and a second clamp body 15, and the first clamp body 14 and the second clamp body 15 are located on both sides of the support plate 1, so The lower end of the support plate 1 is equipped with a support base plate 2, and the rear end of the support plate 1 is connected to a transmission structure 27 and a servo motor 29 near the middle, and the transmission structure 27 is located between the servo motor 29 and the support plate 1. Position, the lower end of the servo motor 29 is equipped with a support base 28, the upper end of the support plate 1 is installed with a connecting column 3, the inside of the first clamp body 14 is provided with a first inner cavity 16, and the second clamp The inside of the main body 15 is provided with a second inner cavity 17, and one side of the support plate 1 is installed near the upper position with a first fixing seat 6, ...

Embodiment 2

[0049] The workpiece to be processed is placed in the first inner cavity 16 and the second inner cavity 17. The workpiece to be processed can be an automobile part, start the servo motor 29, control the speed of the connecting shaft 35 through the reducer 34, and use the hydraulic cylinder to control the first Clamping and loosening of the clamp body 14 and the second clamp body 15;

[0050] The up and down rotation of the fifth connecting rotating column 39 is controlled by the sixth fixed seat 38, the clamping seat 32 is clamped and loosened by the transmission column 30, the second clamp body 15 is rotated up and down, and the lifting column 26 is stretched up and down. Utilize the clamping seat 32 to clamp and loosen the second clamp body 15;

[0051] Wherein, when the second clamp body 15 is loose, the second stopper 13 and the fourth stopper 19 rotate to the rear of the second clamp body 15, the lifting column 26 moves downward, and the second stopper 13 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com