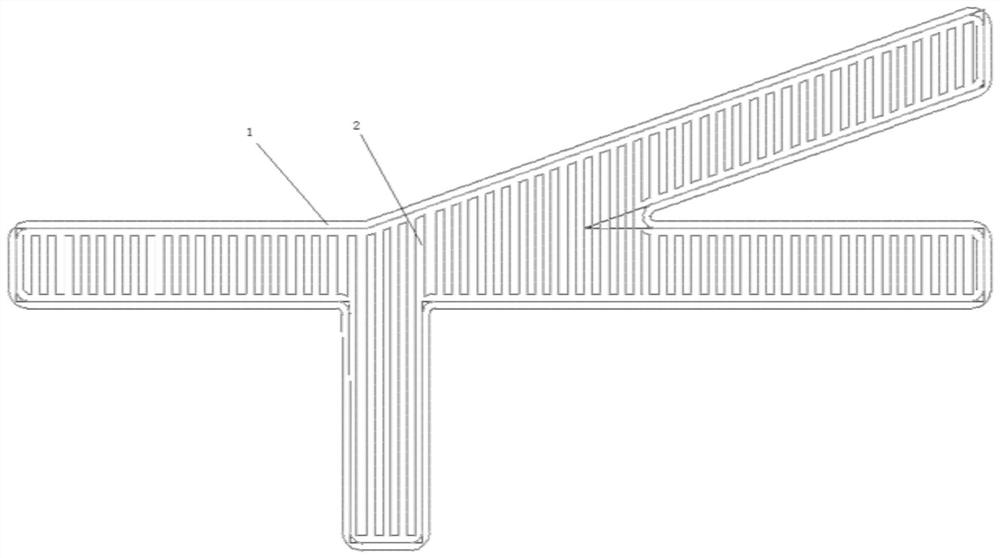

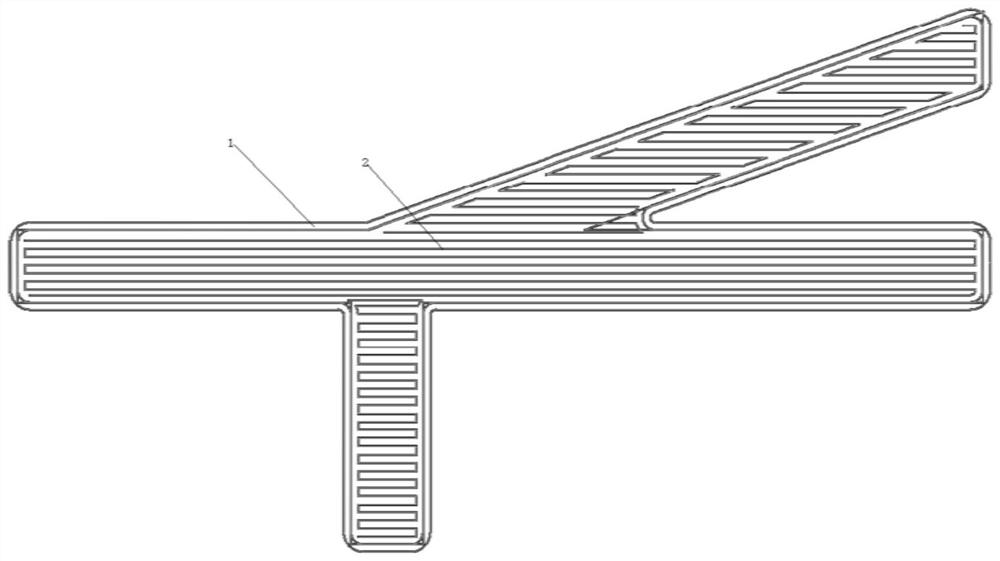

Manufacturing forming method of electric arc fuse additive

A technology of additive manufacturing and forming methods, which is applied in the direction of manufacturing tools, additive processing, arc welding equipment, etc., can solve the problems of metal loss at the boundary of structural parts, affect surface forming quality, and affect deposition efficiency, etc., to improve forming Efficiency and quality, improvement of surface forming quality, effect of increasing deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] In the above-mentioned molding method of reducing heat input, the specific method in the deposition process is:

[0033] The first layer: the deposition heat input current is 180A-220A, the voltage is 21V-29V, the internal filling deposition heat input current is: 180-190A, the wire feeding speed is: 1.5m / min-5m / min, and the welding speed is: 0.15 m / min~0.5m / min, ion gas flow rate: 1.2L / min~4L / min; protective gas flow rate: 8L / min~12L / min; interlayer cooling time 0.5min~10min;

[0034] The second layer: deposition heat input current is 175A~210A, wire feeding speed: 1.5m / min~5m / min, welding speed: 0.15m / min~0.5m / min, ion gas flow: 1.2L / min~ 4L / min; protective gas flow: 8L / min~12L / min; interlayer cooling time 0.5min~10min;

[0035] The third layer: profile deposition heat input current is 170A ~ 200A, wire feeding speed: 1.5m / min ~ 5m / min, welding speed: 0.15m / min ~ 0.5m / min, ion gas flow: 1.2L / min ~4L / min; protective gas flow: 8L / min~12L / min; interlayer cooling time 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com