Tobacco drying and smashing device

A technology for drying, pulverizing, and tobacco, which is applied to tobacco, tobacco preparation, tobacco processing, etc., can solve problems such as poor pulverization effect, influence device operation, and blockage of filter meshes, and achieve the effect of improving drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

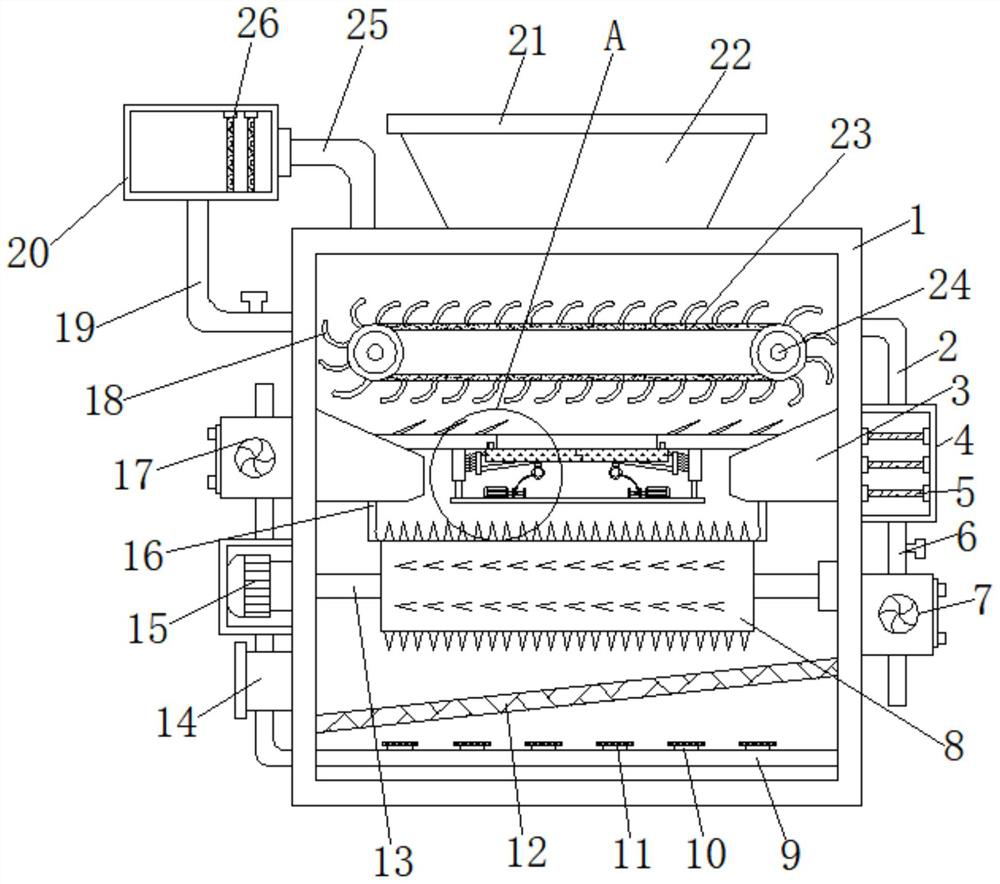

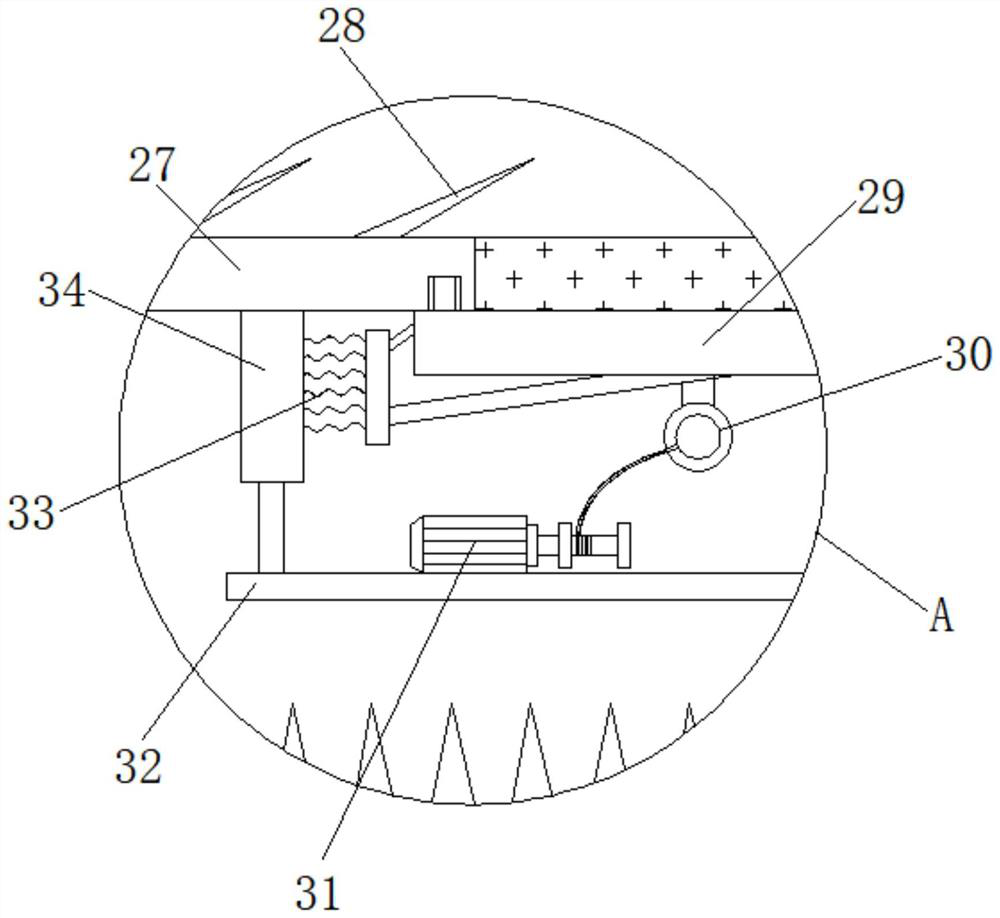

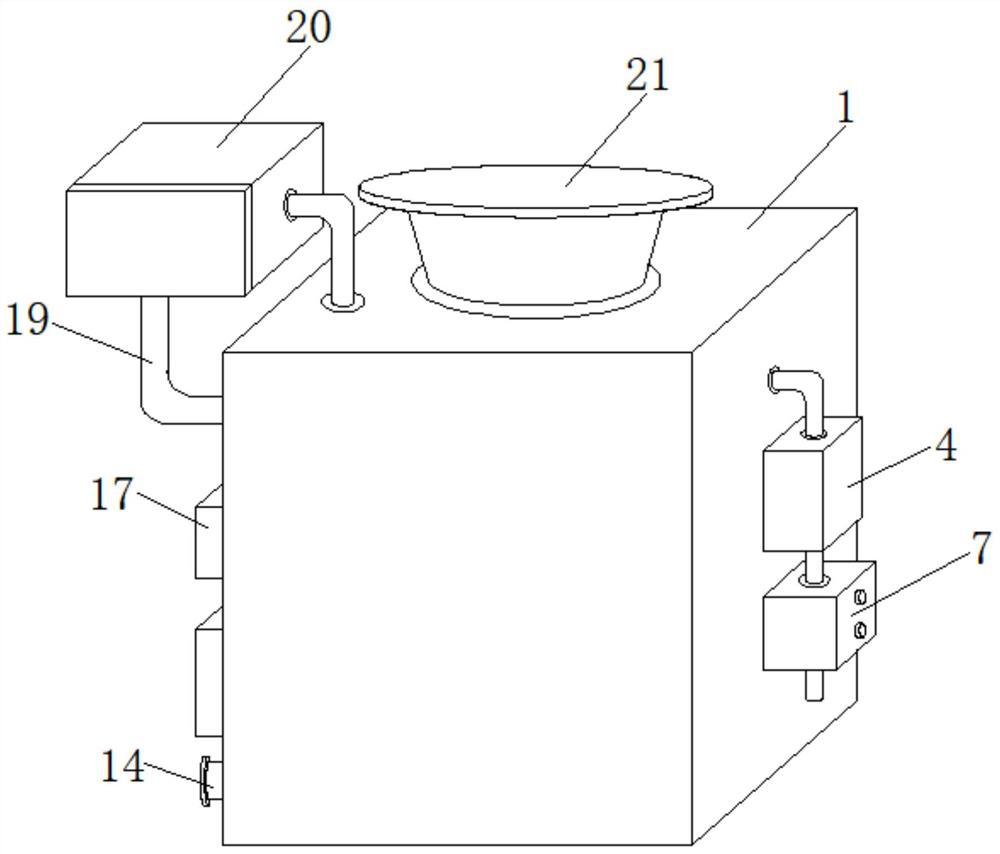

[0032] refer to Figure 1-3 , a tobacco drying and crushing device, comprising a box body 1, an opening is opened on the top outer wall of the box body 1, and a feeding hopper 22 is welded in the opening, and a cover plate 21 is arranged on the top outer wall of the feeding hopper 22, and the box body One side of the outer wall of 1 is connected with a first blower 7 by bolts, and a first connecting pipe 6 is plugged into one side of the first blower 7, and one end of the first connecting pipe 6 is plugged with a heating box 4, and the heating box 4 The inner walls on both sides of the heating box are provided with resistance wires 5, one end of the heating box 4 is plugged with an air inlet pipe 2, and one end of the air inlet pipe 2 extends to the inside of the box body 1, and one side of the outer wall of the box body 1 is connected by a second bolt. A motor 15, and one end of the output shaft of the first motor 15 is provided with a rotating rod 13, the peripheral outer wa...

Embodiment 2

[0036] refer to Figure 4 , a drying and pulverizing device for tobacco. Compared with Embodiment 1, the top and bottom inner walls of the drying box 20 are connected with a mounting plate 35 by bolts, and the outer wall of one side of the mounting plate 35 is connected with a second Two drying plates 36.

[0037] Working principle: when in use, people first add tobacco to the inside of the box body 1 through the feeding hopper 22, and then people start the first blower 7 and the resistance wire 5, and the resistance wire 5 can heat the cold air blown by the first blower 7, Then it blows into the inside of the box body 1, and at the same time, the transmission roller 24 drives the arc-shaped rack 18 to transfer and turn the tobacco inside the box body 1, which can effectively avoid the tobacco at the air inlet pipe 2 and the tobacco at the end of the air inlet pipe 2. There is a large temperature and humidity difference in the tobacco, which can fully dry the tobacco inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com