A circuit board locking device with damping and vibration reduction functions

A damping and circuit technology, applied in the direction of printed circuit components, printed circuit stress/deformation reduction, etc., can solve the problems of large installation space, numerous electronic components, complex process, etc., to meet the requirements of installation reliability, improve the mechanical environment, Guaranteed installation and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] An inertial measurement combination box is subjected to random vibration of 28.96g. After measurement, the vibration level of its in-line circuit board assembly has reached 62.48g. During the test, the circuit board components will appear loose and fall off. can not work. After failure analysis, it is decided to adopt the present invention for both the motherboard and the three direct plug-in boards.

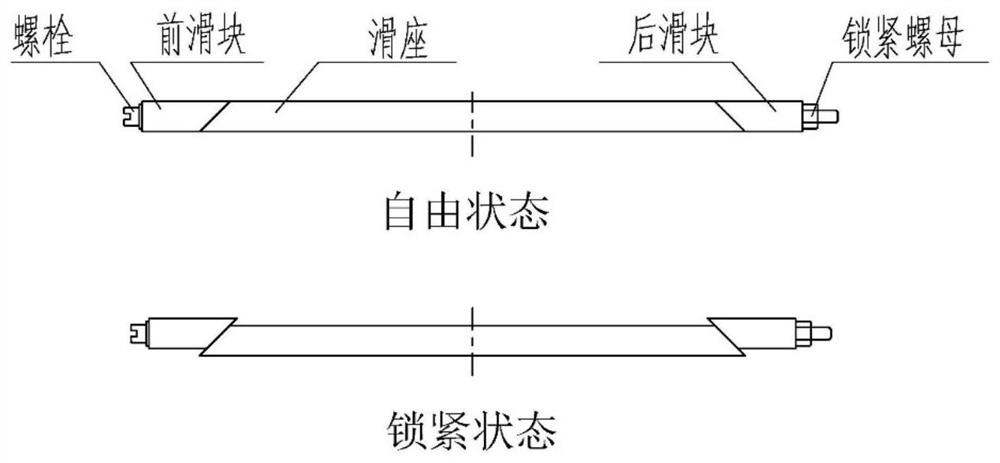

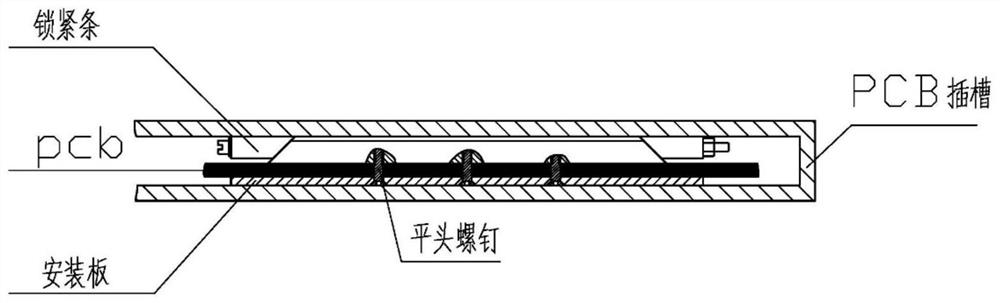

[0053] Motherboard with the present invention: total length L=144, width b=7mm, width of the rubber parts of the damping locking strip and the length of the locking structure of the arc-shaped protrusion of the restraining plate of the damping locking strip l=9mm, between the rubber parts of the damping locking strip The gap a=36mm, the thickness H of the rubber part of the damping locking strip is 6mm, the thickness of the restraining plate of the damping locking strip t1=1mm, the height of the arc-shaped convex locking structure h1=1mm, and the thickness t2 of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com