Sealing test device for sectional type large-diameter pipeline joint

A technology of pipe interface and sealing test, applied in the field of municipal engineering, can solve the problems of waste of water resources, long pumping time, difficulty in judging water leakage points, etc., to achieve accurate measurement, improve detection efficiency, and reduce pumping time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

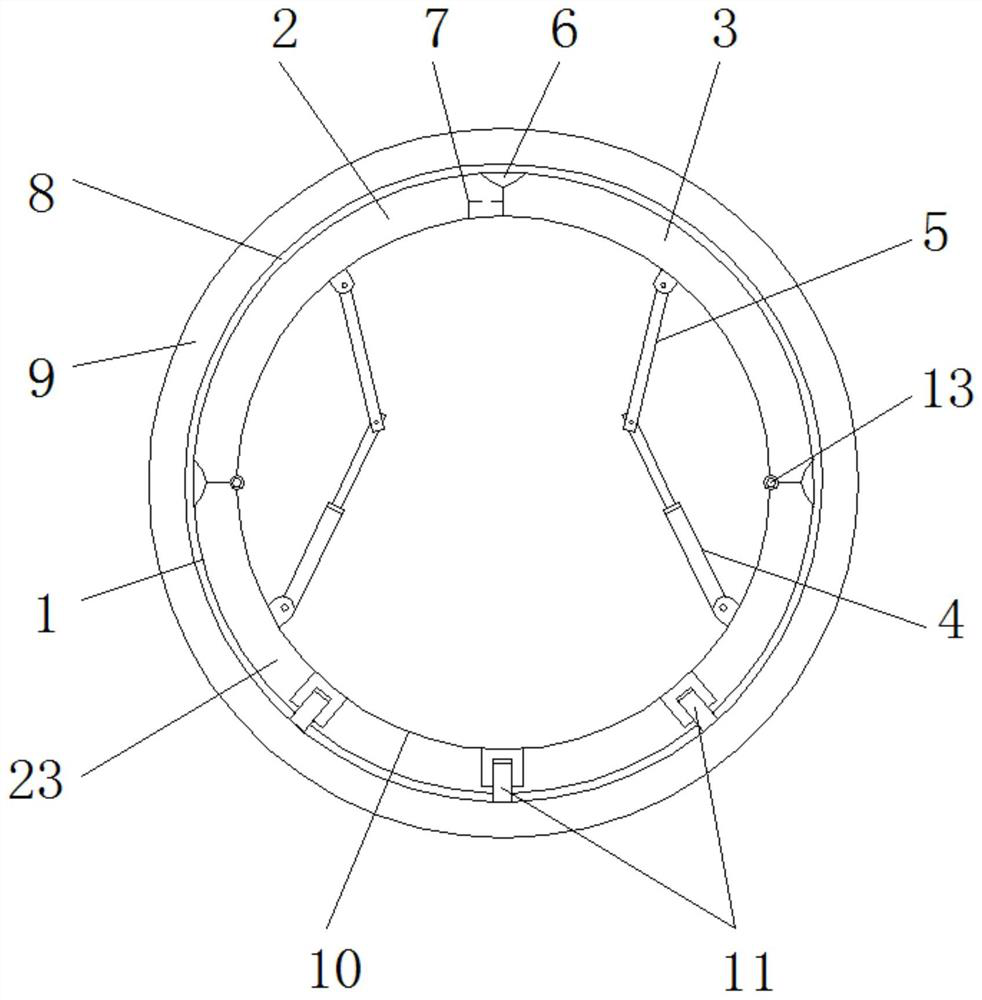

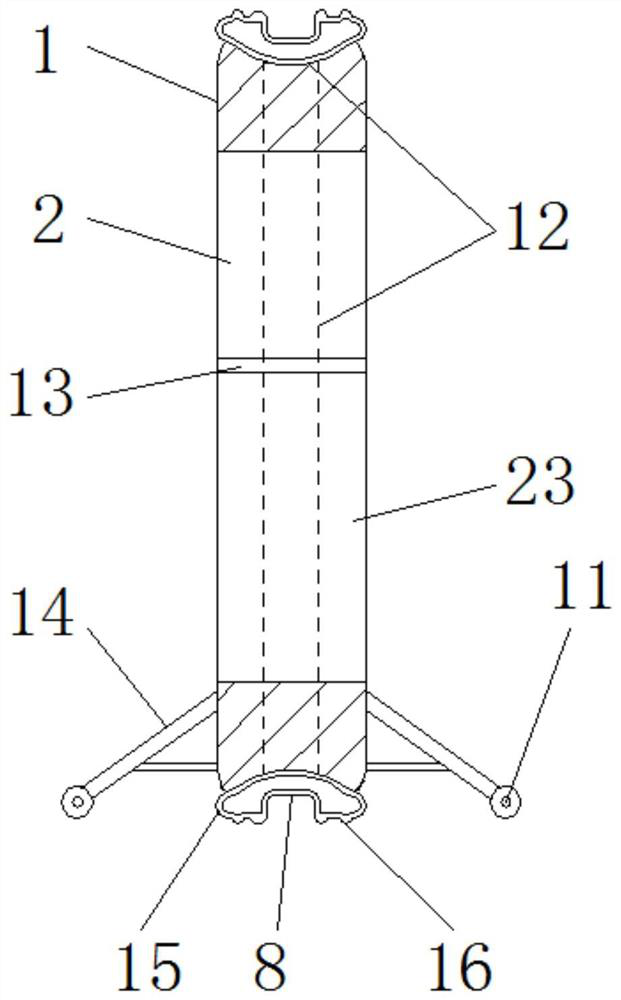

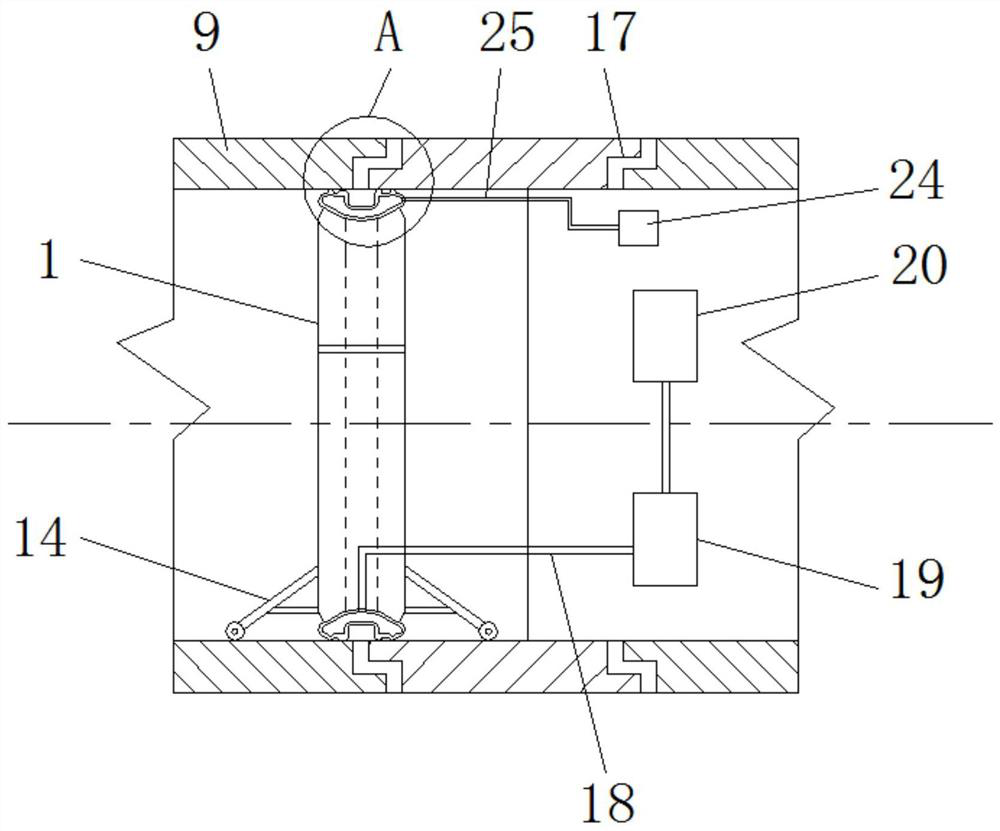

[0036] Such as figure 1 As shown, a sealing test device for segmented large-diameter pipe joints includes an annular support body 1 adapted to the inner wall of the pipe, a hydraulic source, a stretching mechanism, and arcs respectively adapted to the inner wall of the support body 1. Shaped base 23 and unfold frame.

[0037] The support body 1 is arranged in the pipe wall 9 and is located at the pipe joint 17 of two adjacent pipes, the base 23 is arranged on the inner wall of the support body 1, and the base 23 is arranged on the support The lower part of the inner wall of the main body 1, the deployment frame is located in the support body 1, and the two ends of the deployment frame are rotatably connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com