Novel water stop structure for preventing permanent joint of concrete dam from leaking water

A concrete dam, permanent technology, applied in water conservancy engineering, marine engineering, construction and other directions, can solve problems such as hidden dangers of engineering, submerged observation instruments, maintenance and plugging difficulties, etc., to prevent water leakage, convenient construction, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

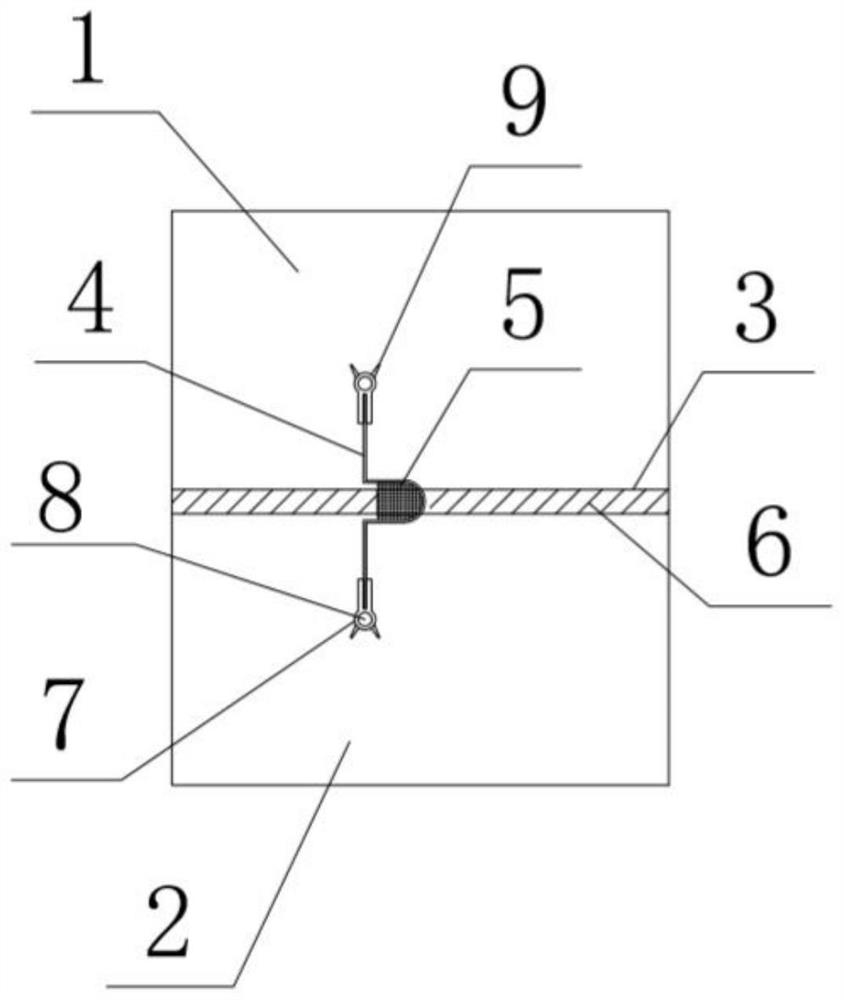

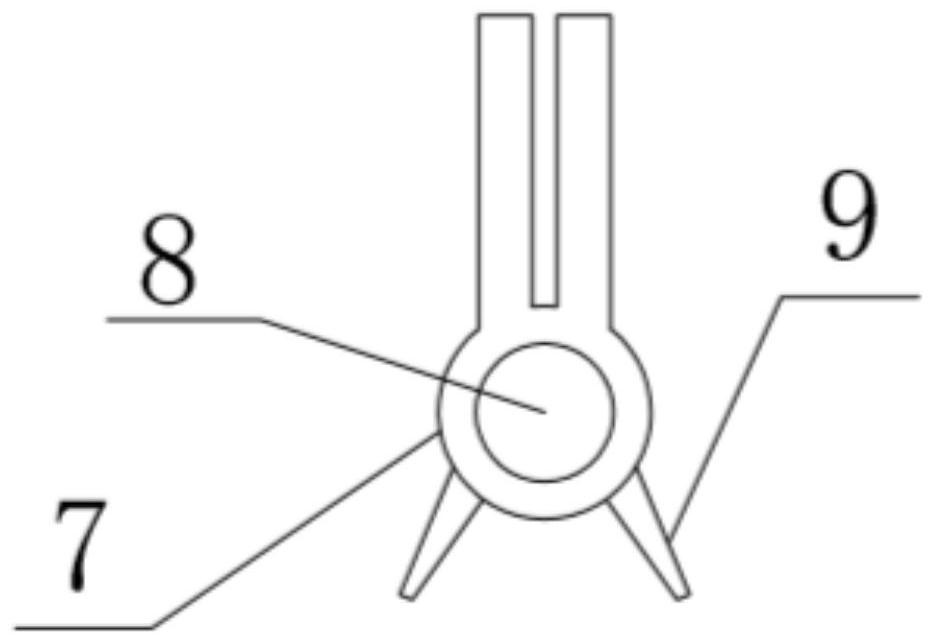

[0011] Such as figure 1 and figure 2 As shown, a new type of water-stop structure to prevent water leakage from the permanent joints of concrete dams, there is a permanent joint 3 between the first dam section 1 and the first dam section 2, and a high-pressure closed-hole plate 6 is set between the permanent joints 3; The convex water-stop copper sheet 4 is set, the boss of the water-stop copper sheet 4 is located at the span permanent joint 3, and the asphalt linoleum 5 is arranged inside it, and the two ends of the water-stop copper sheet 4 are buried in the first dam section 1 and the first dam section respectively. Between the dam sections 2, an inflatable "spherical" water-stop structure 7 is arranged at both ends of the water-stop copper sheet 4, and an inflatable cavity 8 is arranged inside the inflatable "spherical" water-stop structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com