Method for recovering copper from acidic copper-containing etching solution and preparing cuprous oxide

A cuprous oxide and copper etching technology, applied in rotary drum furnaces, crucible furnaces, furnaces, etc., can solve problems such as difficult operation and maintenance, low economic value, complex structure, etc., and achieve significant water saving, environmental protection, and good recycling Utilization rate, effect of high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

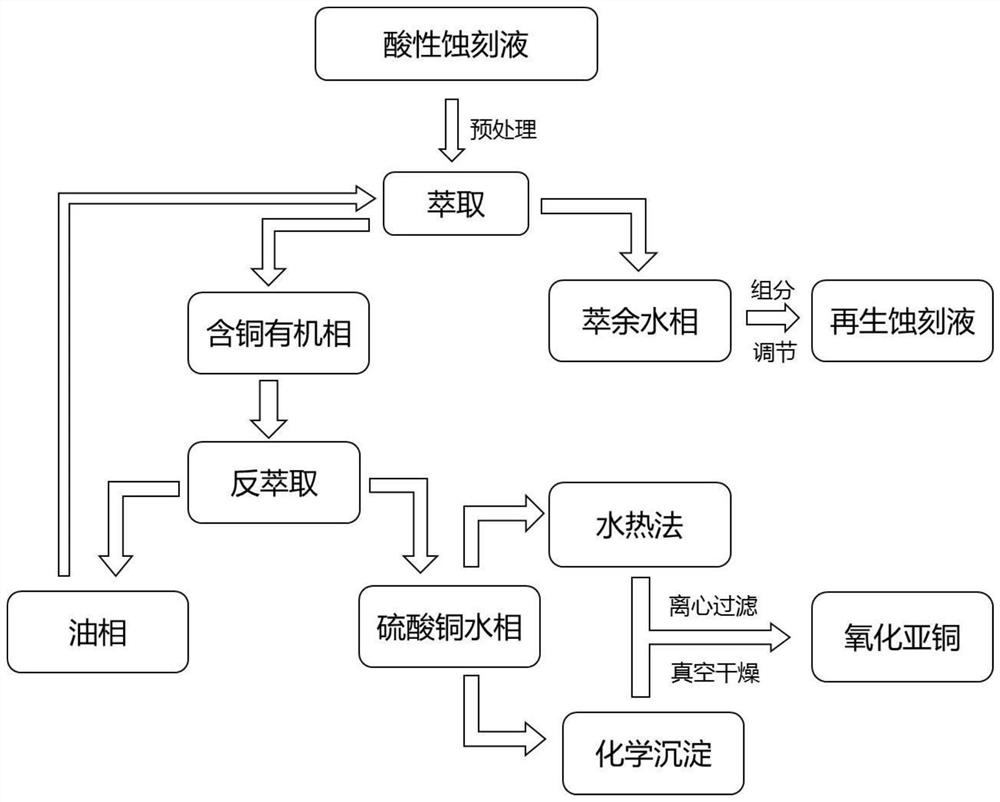

Embodiment 1

[0036] An acidic etching waste solution, Cu 2+ The concentration is 200g / L, H + The concentration is 2.5mol / L, containing a lot of chloride ions. Such as figure 1 As shown in the schematic diagram of the process flow, the acidic copper-containing etching waste liquid is pre-filtered to remove fine insoluble particles in the industrial acidic copper-containing etching waste liquid, and then an appropriate amount of NaOH is added to adjust the pH value of the solution to 2-4, and sequentially add Appropriate amount of Na 2 SO 4 and BaCO 3 , stand still for 60 minutes, use a precision filter to remove the precipitate, add an appropriate amount of ammonia water, and adjust the pH value to 2-4 again to obtain a crude copper-containing solution. Use MextralDT100 diluted extraction agent Mextral984H to extract the copper ions in the crude copper solution, wherein the concentration of the extraction agent is 50%, the volume ratio of the extraction agent to the copper-containing e...

Embodiment 2

[0038] An acidic etching waste solution, Cu 2+ The concentration is 150g / L, H + The concentration is 2mol / L, containing a large amount of chloride ions. Such as figure 1 As shown in the schematic diagram of the process flow, the acidic copper-containing etching waste liquid is pre-filtered to remove fine insoluble particles in the industrial acidic copper-containing etching waste liquid, and then an appropriate amount of NaOH is added to adjust the pH value of the solution to 2-4, and sequentially add Appropriate amount of Na 2 SO 4 and BaCO 3, stand still for 60 minutes, use a precision filter to remove the precipitate, add an appropriate amount of ammonia water, and adjust the pH value to 2-4 again to obtain a crude copper-containing solution. Use MextralDT100 diluted extraction agent Mextral984H to extract the copper ions in the blister copper solution, wherein the concentration of the extraction agent is 40%, the volume ratio of the extraction agent to the copper-cont...

Embodiment 3

[0040] An acidic etching waste solution, Cu 2+ The concentration is 50g / L, H + The concentration is 0.7mol / L, containing a lot of chloride ions. Such as figure 1 As shown in the schematic diagram of the process flow, the acidic copper-containing etching waste liquid is pre-filtered to remove fine insoluble particles in the industrial acidic copper-containing etching waste liquid, and then an appropriate amount of NaOH is added to adjust the pH value of the solution to 2-4, and sequentially add Appropriate amount of Na 2 SO 4 and BaCO 3 , stand still for 60 minutes, use a precision filter to remove the precipitate, add an appropriate amount of ammonia water, and adjust the pH value to 2-4 again to obtain a crude copper-containing solution. Use MextralDT100 diluted extractant Mextral984H to extract copper ions in blister copper solution, wherein the concentration of extractant is 20%, the volume ratio of extractant to copper-containing etching waste liquid is (O / A) 5:1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com