Drop-preventing device for logistics transportation

A technology for logistics transmission and anti-dropping, which is applied to the device for preventing goods from falling at corners, logistics transmission anti-dropping devices, and anti-dropping devices. It can solve problems affecting logistics transmission work, cargo damage, and conveyor belt dropping , to achieve the effect of smooth item transmission, less damage and less friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

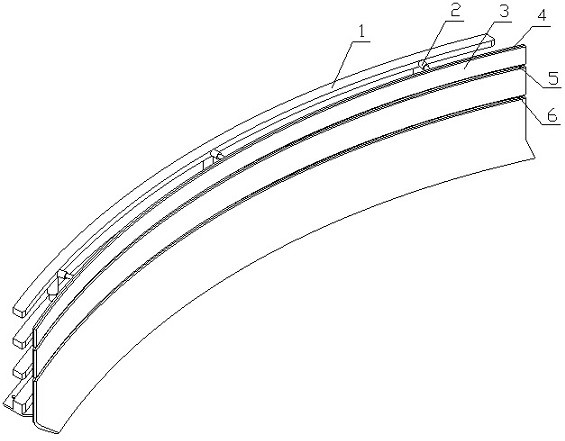

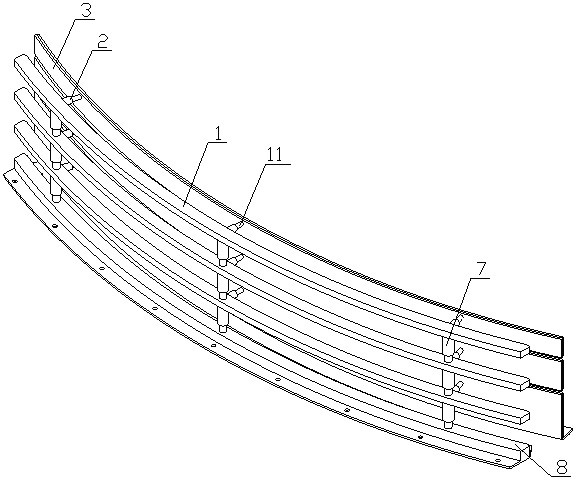

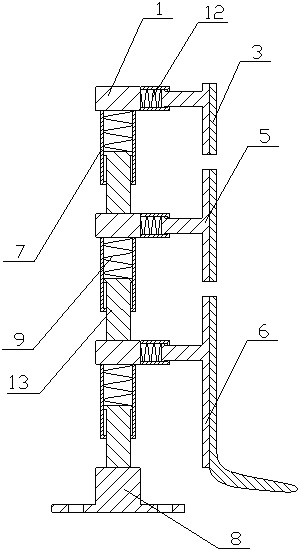

[0019] A logistics transmission anti-drop device of the present invention is realized in the following way: a logistics transmission anti-drop device of the present invention consists of a support plate (1), a buffer sleeve (2), a protective plate (3), and an upper fixing plate (4) , middle fixing plate (5), lower fixing plate (6), telescopic sleeve (7), fixing seat (8), buffer spring (9), buffer rod (11), elastic spring (12) and telescopic rod (13) Composition, three support plates (1) are located above the fixed seat (8), the three support plates (1) are equidistantly stacked, and a plurality of telescopic sleeves are arranged between two adjacent support plates (1) (7), one end of the telescopic sleeve (7) is connected to the support plate (1), one end of the telescopic rod (13) is placed in the other end of the telescopic sleeve (7), and the telescopic rod (13) The other end of the buffer spring (9) is connected to the lower support plate (1), the buffer spring (9) is set ...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is: the upper defense plate is additionally provided with a plurality of balls (10), the middle defense plate is additionally provided with a plurality of balls (10), and the lower defense plate is additionally provided with a plurality of balls (10). There are multiple balls (10); when in use, the sliding friction is converted into rolling friction, which can further reduce the friction when the goods collide, and make the goods transported more quickly;

[0024] The upper fixing plate (4) is an arc-shaped plate, the middle fixing plate (5) is an arc-shaped plate, and the lower fixing plate (6) is designed as an arc-shaped plate, which can match the arc shape at the corner of the conveyor belt. Edge matching, good lamination effect, good blocking and buffering effect on goods;

[0025] The bottom of the protective plate (3) on the lower fixing plate (6) is designed to be bent horizontally, which can block the good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com