Method and device for manufacturing safety vent of cap plate for secondary battery, method for manufacturing cap plate using method for manufacturing safety vent, and cap plate for secondary battery manufactured by method for manufacturing cap plate

A manufacturing method and secondary battery technology, applied to batteries, manufacturing tools, shearing devices, etc., can solve problems such as high production unit price of roof, hard safety valve, etc., to save power energy, reduce forging torque, and improve manufacturing production sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings. However, it should be understood that the present invention can be realized in various forms and is not limited to the described embodiments.

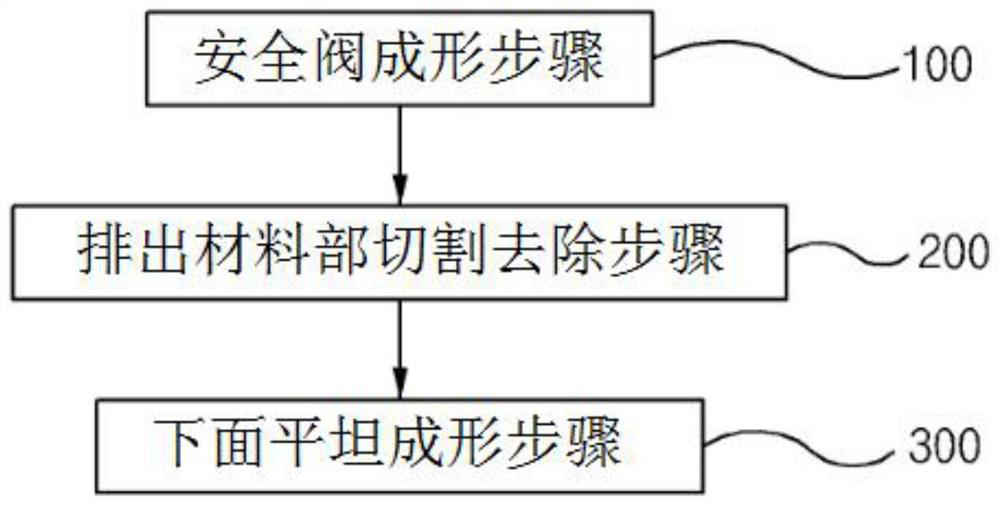

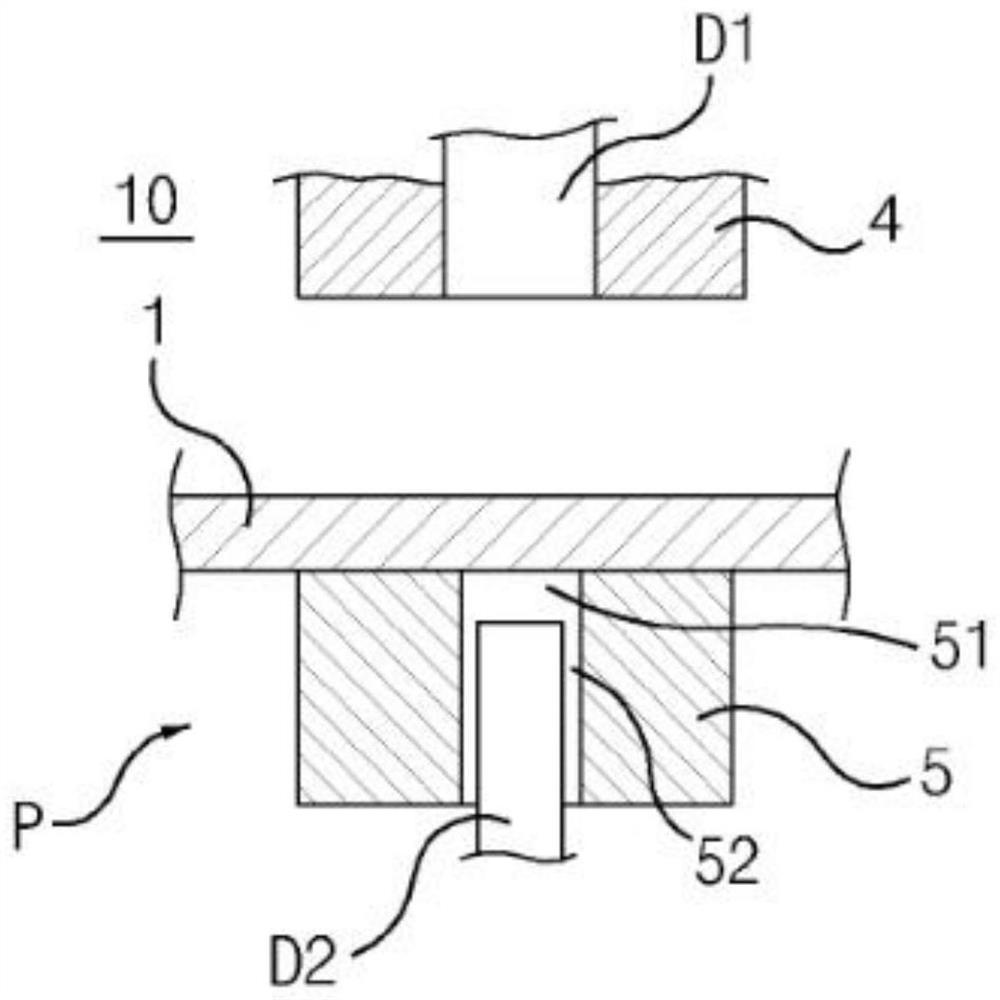

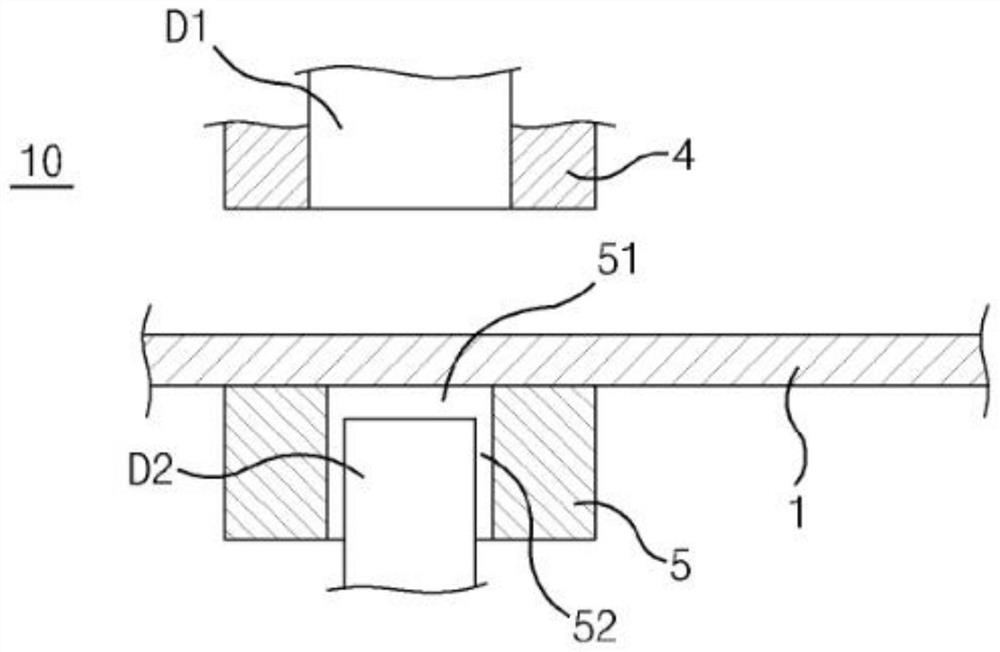

[0048] figure 1It is a process drawing showing the manufacturing method of the safety valve according to the present invention, FIG. 2 shows a drawing of the forming step of the safety valve in the manufacturing method of the safety valve according to the present invention, and FIG. 3 shows cutting and removal of the discharge material part in the manufacturing method of the safety valve according to the present invention As a diagram of the steps, FIG. 4 shows diagrams of other embodiments constituting the cutting device of the present invention. And FIG. 5 is a view showing the following flat forming step in the safety valve manufacturing method according to the present invention.

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com