A Calculation Method of Time-varying Mesh Stiffness of Planetary Gears Based on Tooth Profile Correction Method

A time-varying mesh stiffness, planetary gear technology, applied in belt/chain/gear, complex mathematical operations, transmission parts, etc., can solve the problems of inaccurate calculation results, large amount of calculation, cumbersome calculation process, etc. Complexity, improved accuracy, simple and intuitive calculation principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

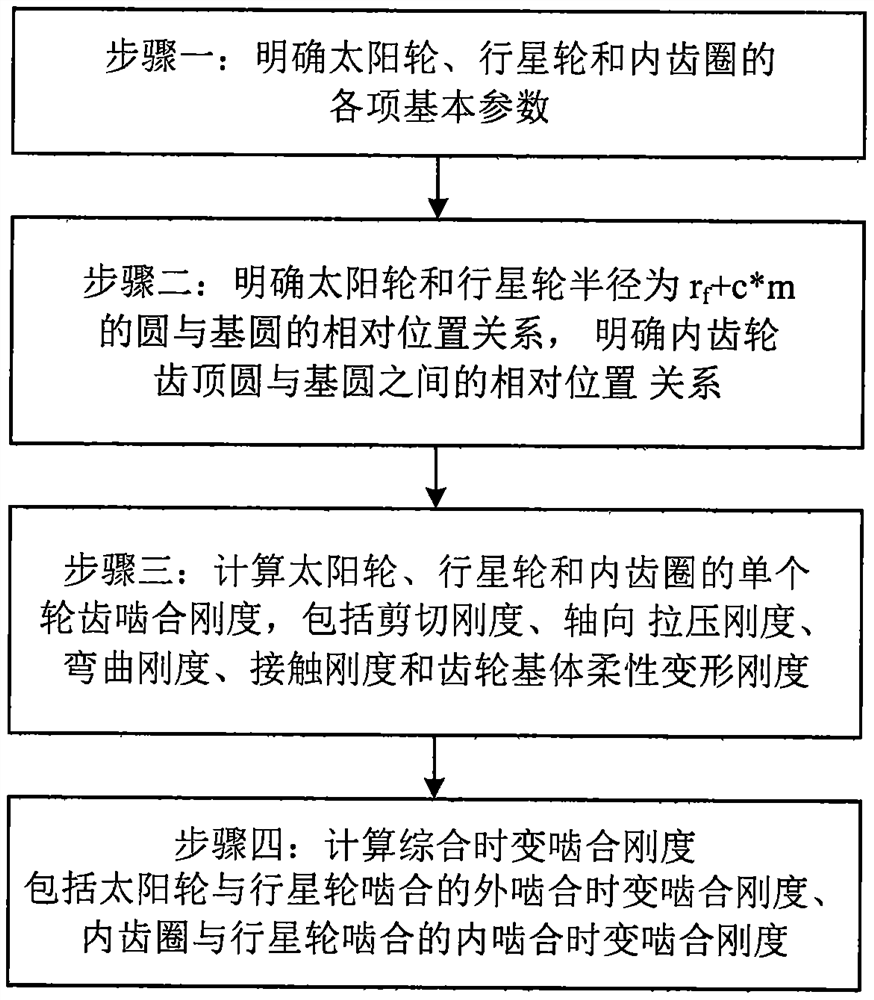

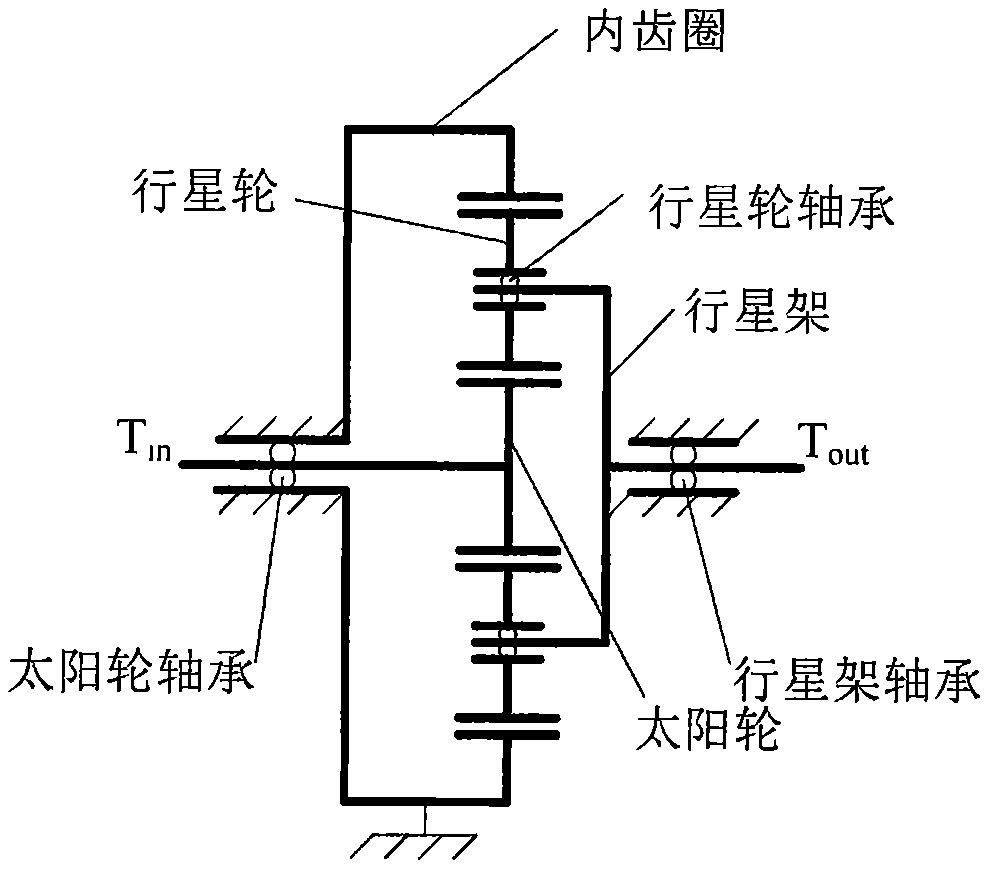

[0108] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 As shown, a method for calculating the time-varying meshing stiffness of planetary gears based on the tooth profile correction method includes the following specific steps:

[0109] Step 1: Define the basic parameters of the sun gear, planetary gear and ring gear, including: number of teeth z, modulus m, tooth width B, addendum height coefficient h a *, head gap coefficient c*, indexing circle pressure angle α, displacement coefficient is x (positive value is taken for positive displacement, negative value is taken for negative displacement), pitch circle pressure angle α w , the shear modulus G of the material, the elastic modulus E of the material, Poisson’s ratio μ, the rotational speed n, and the transmitted power P;

[0110] Table 1 Basic parameters of gears

[0111]

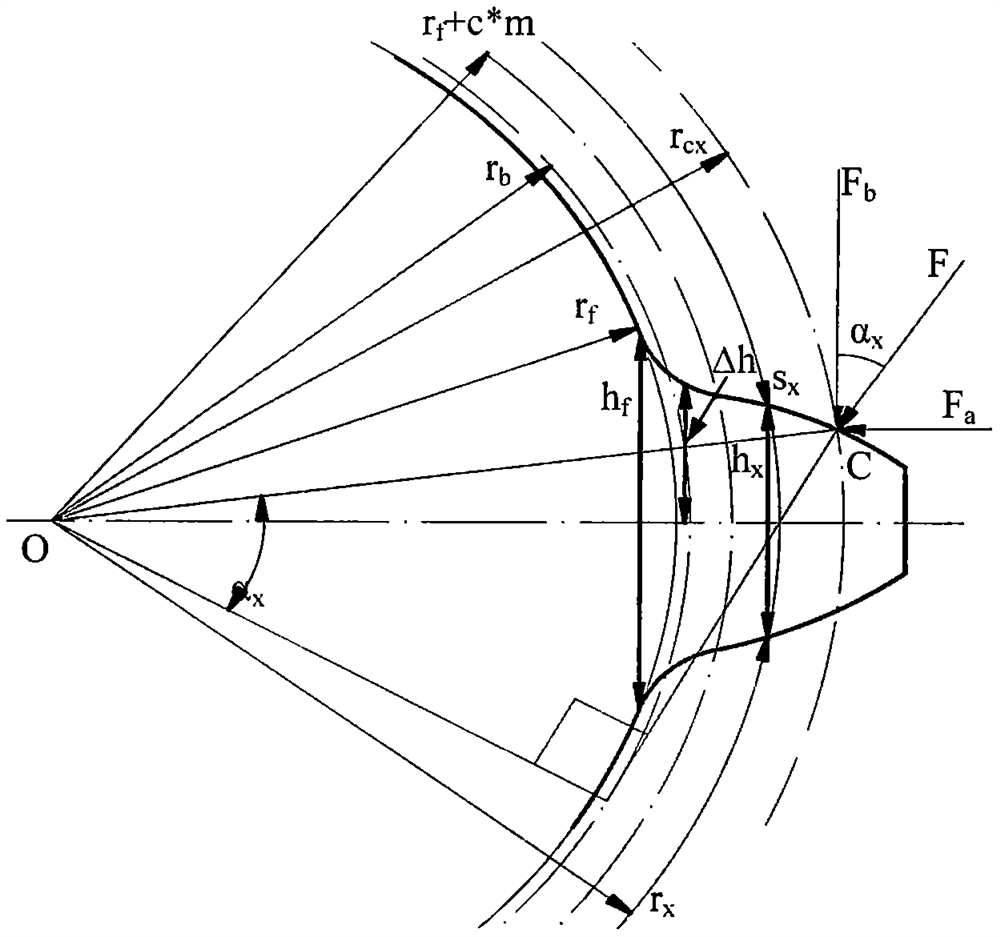

[0112] Step 2: Determine the radius of the sun gear and the planet gear as r f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com