Method for detecting iron content in calcite and dolomite

A detection method, the technology of dolomite, applied in the direction of measuring device, preparation of test samples, color/spectral characteristic measurement, etc., can solve the problem that the detection results cannot be confirmed in time, the supplier’s monitoring results are in doubt, and the speed of the detection report is affected, etc. problems, to achieve the effects of stable test results, scientific test results, data stability and authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

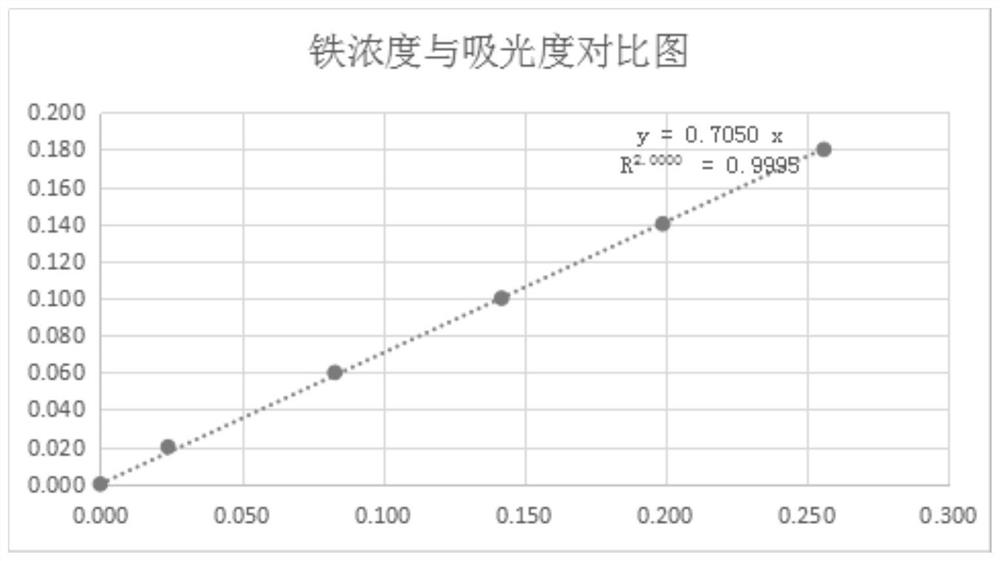

Image

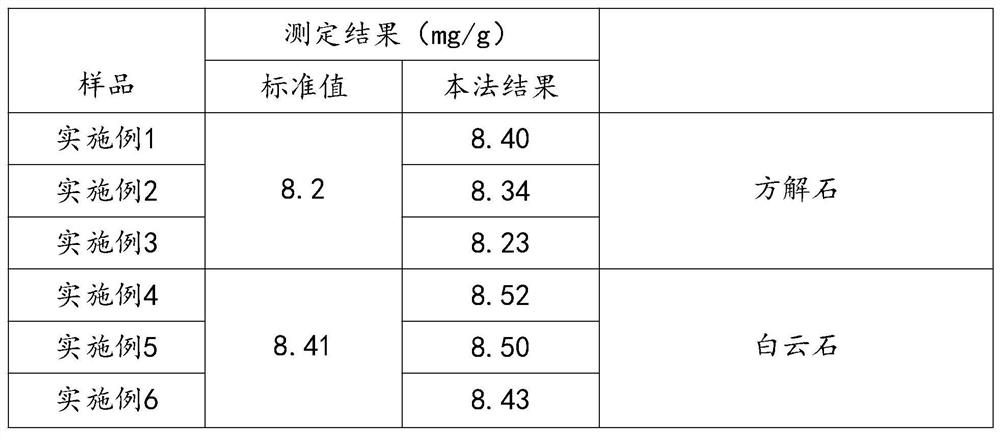

Examples

Embodiment 1

[0026] ——A method for detecting iron content in calcite, comprising the following steps:

[0027] (1) Instrument preparation: UV-1750 ultraviolet-visible spectrophotometer, analytical balance (1 / 10,000 standard);

[0028] (2) Reagent preparation: superior pure reagents of hydrochloric acid, anhydrous sodium carbonate, hydrofluoric acid and boric acid;

[0029] (3) Sample selection: According to GB / T3286, GB / T5762 and GB / T2007 national standard detection theory, the sample is sampled by the quadratic method, and the sample is reduced to 100g;

[0030] (4) Grinding and dissolving the reagent: Grind and pulverize the sample obtained in step (3) through a grinder, and the particle diameter of the pulverized sample is ≤74um, and then put it in a drying box for drying for 2 hours, and the drying is completed Finally, take it out and place it in a desiccator to cool until it reaches room temperature, so as to obtain the reagent;

[0031] Then weigh the dried sample 3.5 and place it...

Embodiment 2

[0034] ——A method for detecting iron content in calcite, comprising the following steps:

[0035] (1) Instrument preparation: UV-1750 ultraviolet-visible spectrophotometer, analytical balance (1 / 10,000 standard);

[0036] (2) Reagent preparation: superior pure reagents of hydrochloric acid, anhydrous sodium carbonate, hydrofluoric acid and boric acid;

[0037] (3) Sample selection: According to GB / T3286, GB / T5762 and GB / T2007 national standard detection theory, the sample is sampled by the quadratic method, and the sample is reduced to 100g;

[0038] (4) Grinding and dissolving the reagent: Grind and pulverize the sample obtained in step (3) through a grinder. After the end, take it out and place it in a desiccator to cool until it reaches room temperature, so as to obtain the reagent;

[0039] Then weigh 4.0g of the dried sample and place it in a platinum pot, then add a mixed solvent of 4 grams of sodium carbonate and 2 grams of boric acid, mix and mix, and then place it i...

Embodiment 3

[0042] ——A method for detecting iron content in calcite, comprising the following steps:

[0043] (1) Instrument preparation: UV-1750 ultraviolet-visible spectrophotometer, analytical balance (1 / 10,000 standard);

[0044] (2) Reagent preparation: superior pure reagents of hydrochloric acid, anhydrous sodium carbonate, hydrofluoric acid and boric acid;

[0045] (3) Sample selection: According to GB / T3286, GB / T5762 and GB / T2007 national standard detection theory, the sample is sampled by the quadratic method, and the sample is reduced to 100g;

[0046](4) Grinding and dissolving the reagent: Grind and pulverize the sample obtained in step (3) through a grinder. The particle diameter of the pulverized sample is ≤74um, and then put it in a drying box for drying for 3 hours, and the drying is completed. Finally, take it out and place it in a desiccator to cool until it reaches room temperature, so as to obtain the reagent;

[0047] Then weigh 4.5g of the dried sample and place it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com