High-accuracy as-fired coal sampling and weighing and checking integrated system and method

A high-precision, weighing technology, used in continuous material flow weighing equipment, sampling, weighing and other directions, can solve the problems of difficult work, difficult to guarantee accuracy, and inability to guarantee errors, to improve the accuracy of measurement, solve the The work is difficult and the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

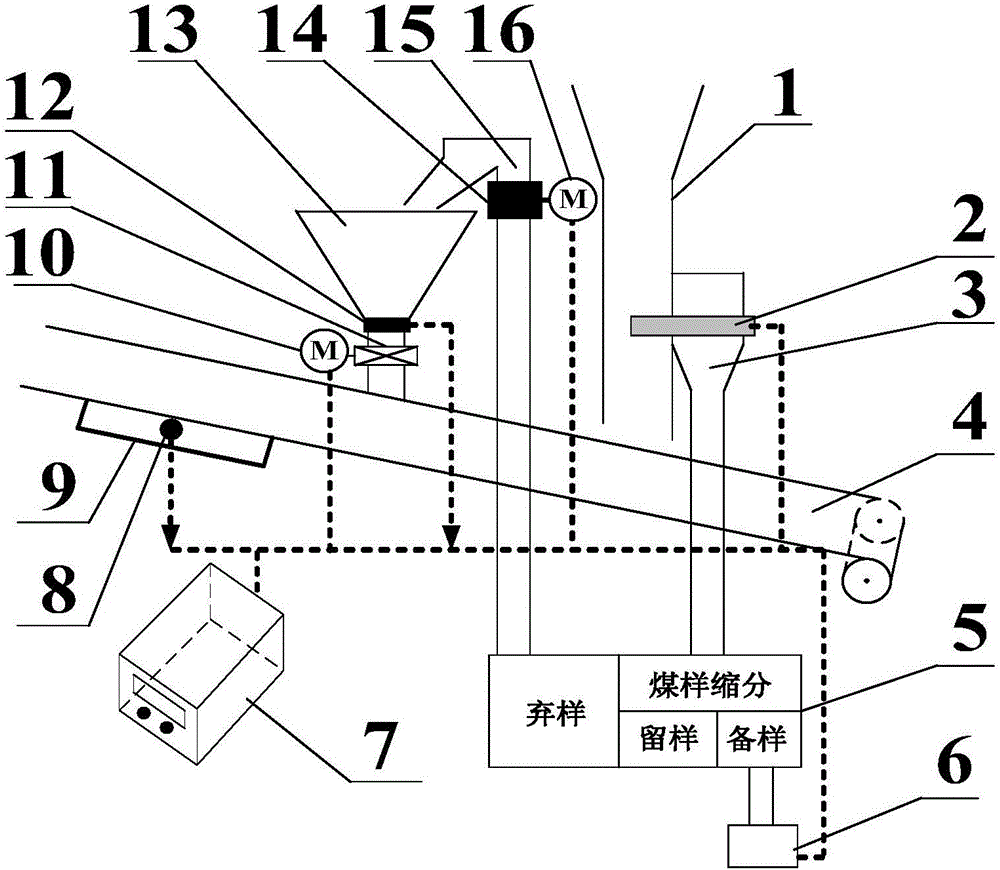

[0011] The present invention provides an integrated system and method for high-precision furnace coal sampling, weighing and verification. The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown in the figure, the furnace coal sampling and weighing verification integrated system consists of a coal drop pipe 1, a coal sampling device 2, a sampling bin 3, a conveyor belt 4, a coal shrinkage and sample retention equipment 5, an automatic packaging and coding equipment 6, and a computer Control unit 7, belt scale gravity sensor 8, belt scale 9, electric door motor 10, electric door 11, coal bunker gravity sensor 12, weighing coal bunker 13, bucket elevator 14, lifting channel 15, bucket elevator lifting motor 16 Composition; wherein, the coal sampling device 2 is installed on one side of the coal falling pipe 1, as an automatic sampling device; the outlet of the sampling bin 3 is connected to the entra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com