Gas-liquid two-phase flow corrosion test device for mountain moisture pipeline

A gas-liquid two-phase flow and corrosion test technology, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as long gaps, difficulty in obtaining corrosion parameters, and inability to truly restore the flow state of pipelines. The effect of saving test resources and reducing corrosion test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

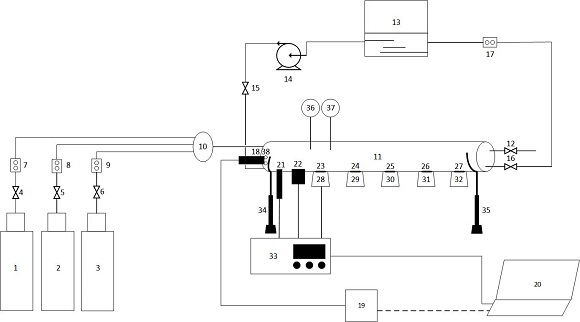

[0021] In the first step, the working electrode (23), the weight loss sample one (24), the weight loss sample two (25), the weight loss sample three (26), and the cross-section observation sample (27) are respectively fixed on the rubber plug one ( 28), rubber plug two (29), rubber plug three (30), rubber plug four (31), rubber plug five (32) are installed on the gas-liquid two-phase flow corrosion test pipe section (11).

[0022] The second step is to adjust the fixed support leg one (34) and the fixed support leg two (35), and set the inclination angle of the gas-liquid two-phase flow corrosion test pipe section (11) and the position of the sample.

[0023] The third step is to open the centrifugal pump (14), the liquid control valve (15), the liquid outlet control valve (16), and the electromagnetic flowmeter (17), so that the test solution enters the gas-liquid two-phase flow corrosion test pipe section (11), and reaches After the ideal liquid level, close the centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com