System for recycling vent natural gas in compressor station

A technology for venting natural gas and compressor stations, which is applied in pipeline systems, gas/liquid distribution and storage, liquid variable capacity machinery, etc. It can solve problems such as inability to pressurize natural gas, lower recovery rate of vented natural gas, and inability to pressurize natural gas , to achieve the effect of increasing the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0054] It should be noted that the pipeline compressor A involved in the embodiment of the present invention is installed between the upstream pipeline and the downstream pipeline, and pressurizes the natural gas in the upstream pipeline so that the natural gas in the upstream pipeline can smoothly flow into the downstream pipeline.

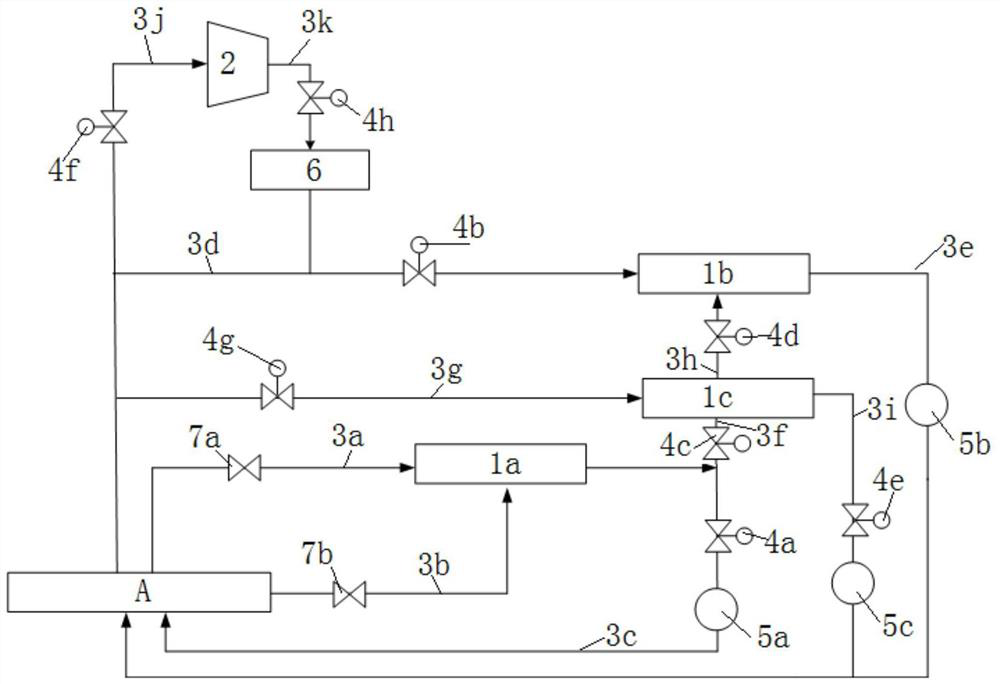

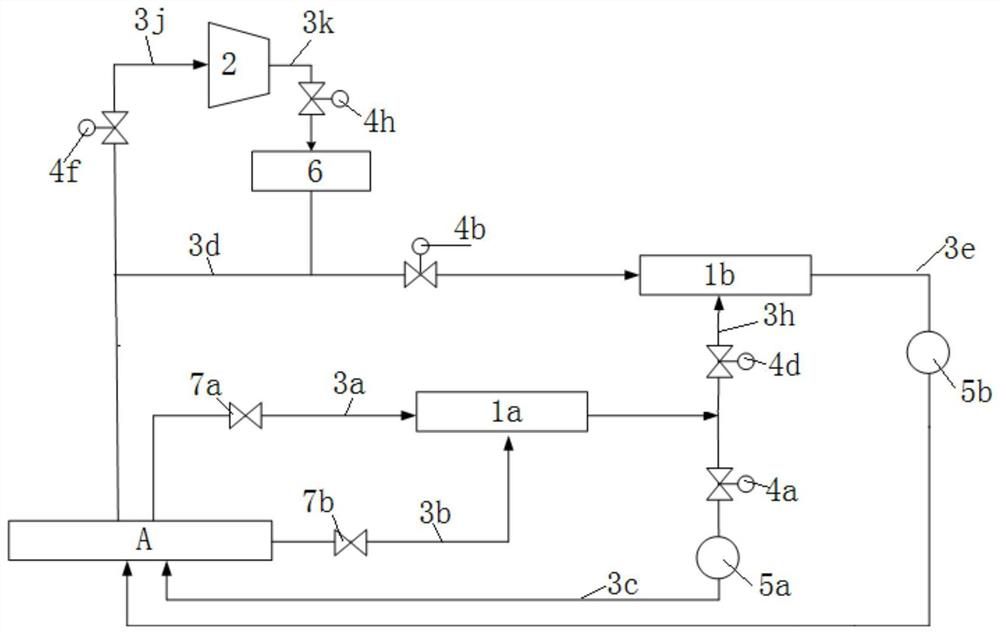

[0055] The embodiment of the present invention provides a system for recovering the emptied natural gas of the compressor station, as shown in the attached figure 1 As shown, the system includes: a multi-stage gas dynamic compressor 1, a gas reciprocating compressor 2, and a controller;

[0056]The high-pressure intake end of the first-stage gas dynamic compressor 1a communicates with the outlet end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com