Double drum mining machine mining process

A mining machine and double-drum technology, applied in ground mining, underground mining, special mining, etc., can solve the problem of cutting and loading thin high-grade mineral materials. There is no good solution, and it is impossible to realize high-value grade mineral material mining. , Difficult to achieve normal operation and other problems, to achieve the effect of improving loading effect, increasing mining adaptability and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

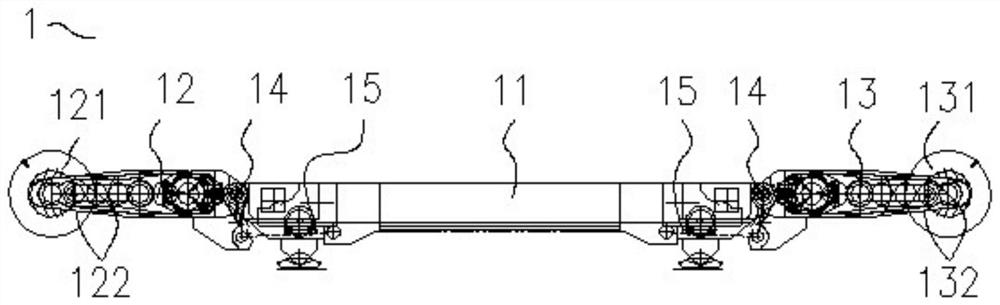

[0055] The invention discloses a mining process of a double-drum mining machine, such as Figure 1-22 As shown, the mining equipment used mainly includes a mining machine 1 , a support 2 and a conveyor 3 . Mining machine 1 comprises fuselage 11, left cutting arm 12, right cutting arm 13, connecting piece 14 and oil cylinder 15, and left cutting arm and right cutting arm are respectively connected with main body 11 by connecting piece and oil cylinder 15, by The expansion and contraction of oil cylinder 15, left cutting arm and right cutting arm swing relative to fuselage respectively and realize height adjustment. The overhanging ends of the left cutting arm 12 and the right cutting arm 13 are equipped with a small diameter left cylinder 121 and a small diameter right cylinder 131 respectively. The conveyor includes a plurality of sequentially connected conveyor troughs for loading and transporting the cut mineral materials. The mining machine is installed on the conveyor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com