Variable valve apparatus for internal combustion engine

A technology for internal combustion engines and valves, which is applied to valve devices, mechanical equipment, engine components, etc. It can solve problems such as increased pumping loss, deviation from the ideal relationship, and excessive residual gas, and achieve the effect of avoiding adverse conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

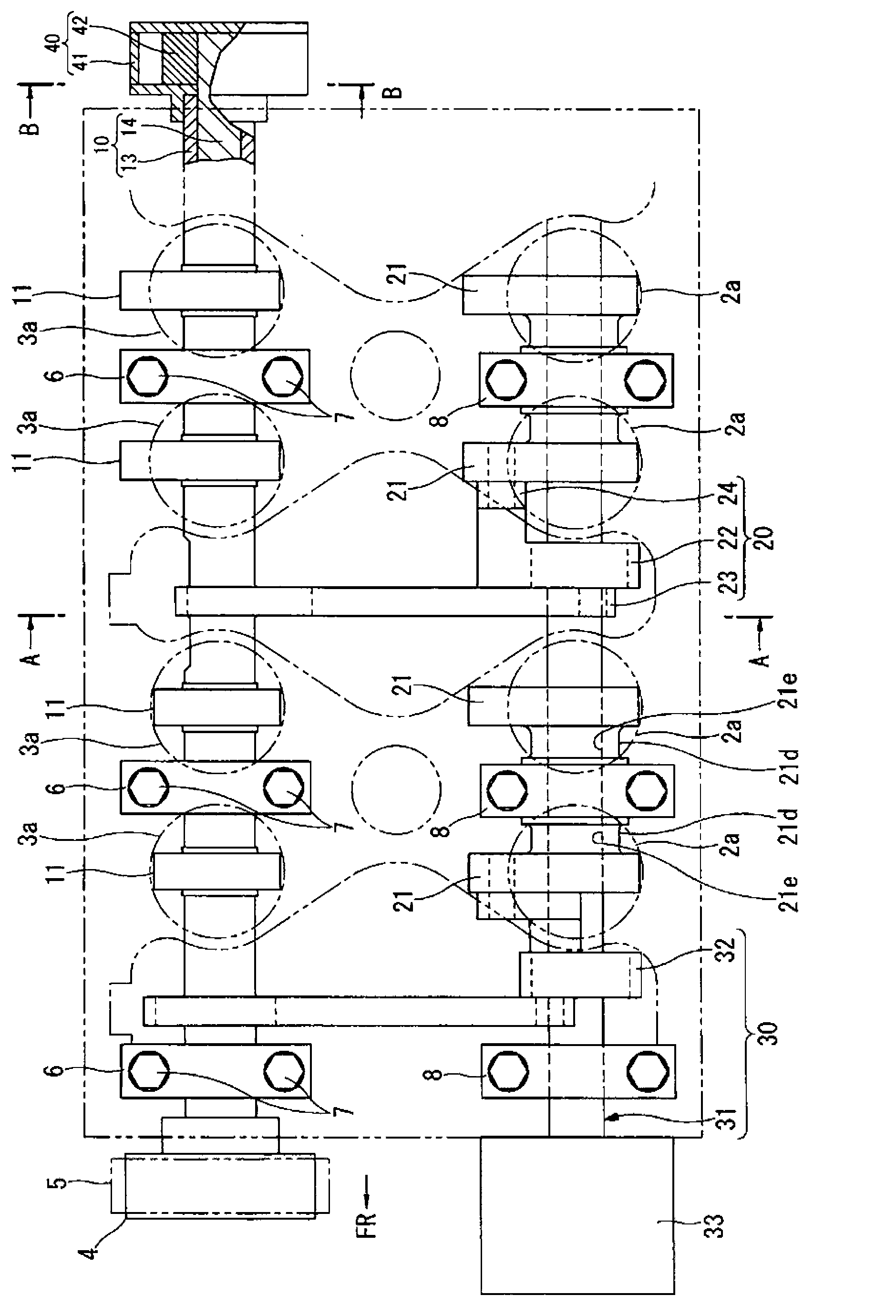

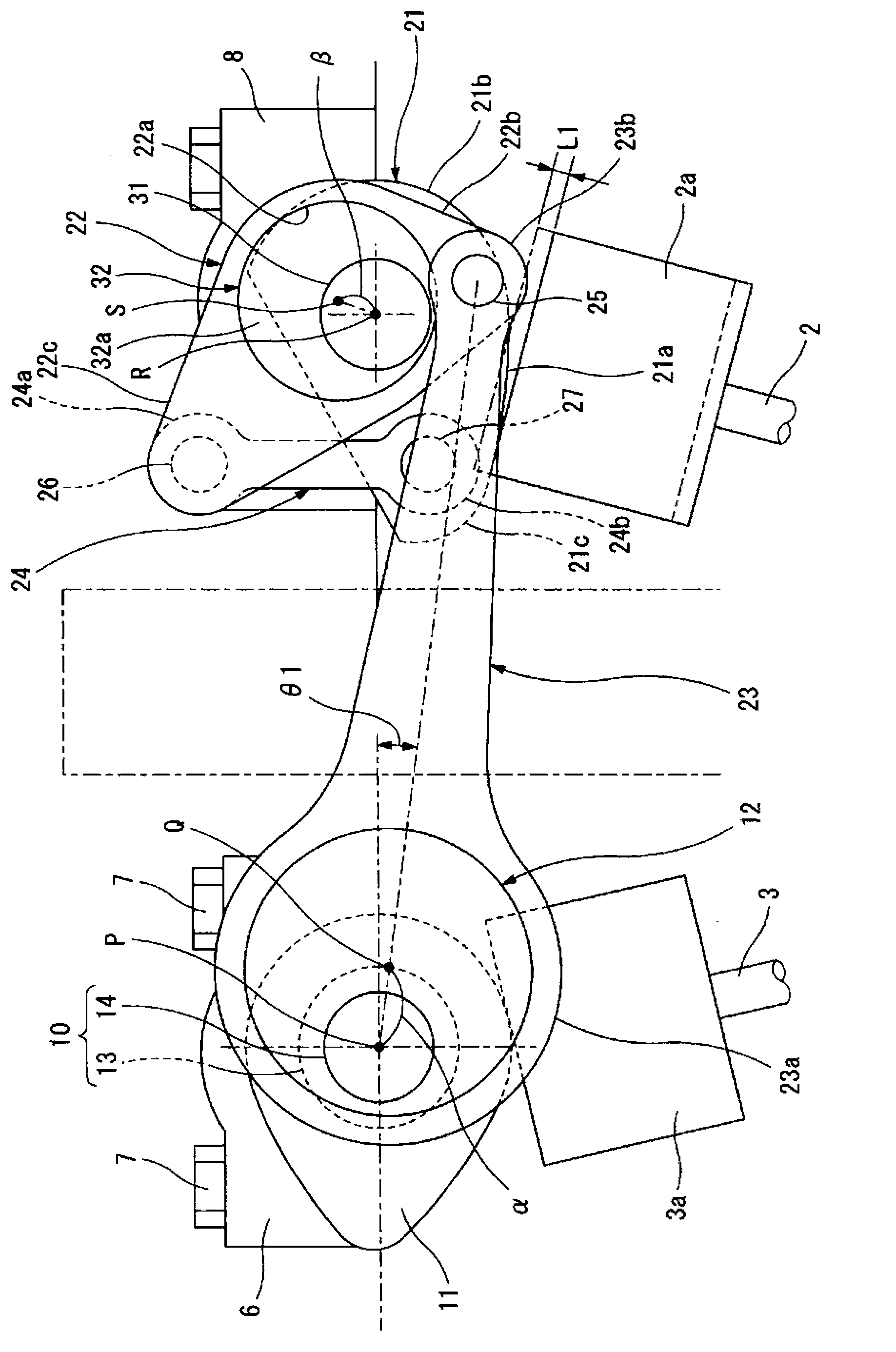

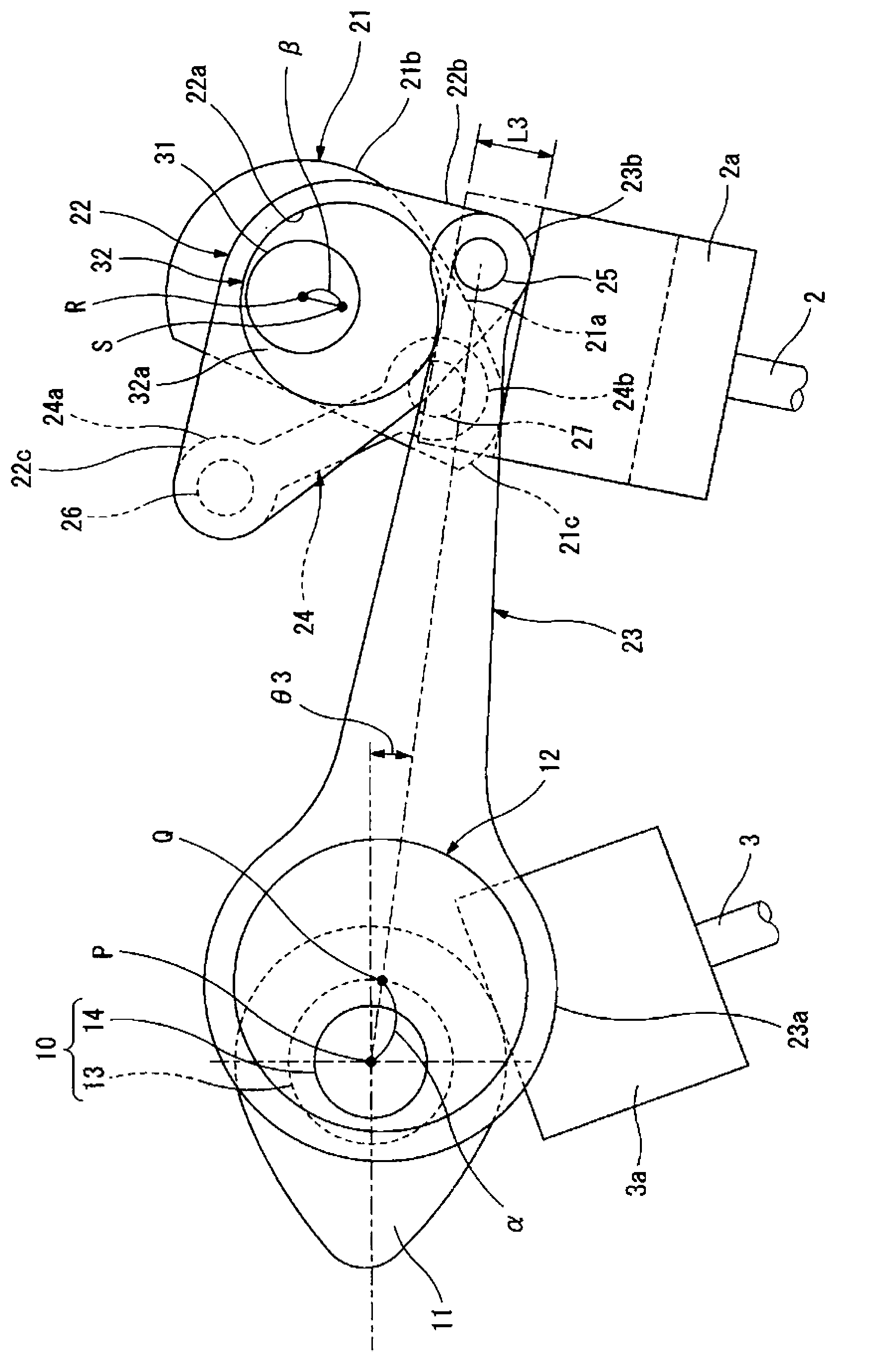

[0043] Hereinafter, each embodiment of the variable valve apparatus for an internal combustion engine according to the present invention will be described in detail with reference to the drawings. In addition, in each of these embodiments, the present invention is applied to a motor vehicle internal combustion engine having two intake valves and two exhaust valves per cylinder.

[0044] That is, if Figure 1~Figure 3As shown, the variable valve device includes: a control shaft 31 corresponding to the intake side camshaft, an exhaust side camshaft 10 forming a double structure described later, a transmission mechanism 20, and a control mechanism as a variable operating angle mechanism. 30. The control shaft 31 and the exhaust-side camshaft 10 are arranged side by side on both sides of the upper part of the cylinder head 1 along the front-rear direction of the internal combustion engine, and the transmission mechanism 20 will be integrally provided on the exhaust-side camshaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com