Rapid mixing type waste paper recycling and deinking device

A hybrid waste paper technology, which is applied in paper recycling, recycling technology, papermaking, etc., can solve the problems of affecting processing efficiency, single stirring method, and reducing the effect of physical impact and pulling, so as to improve efficiency, improve deinking efficiency, The effect of avoiding the swirl phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

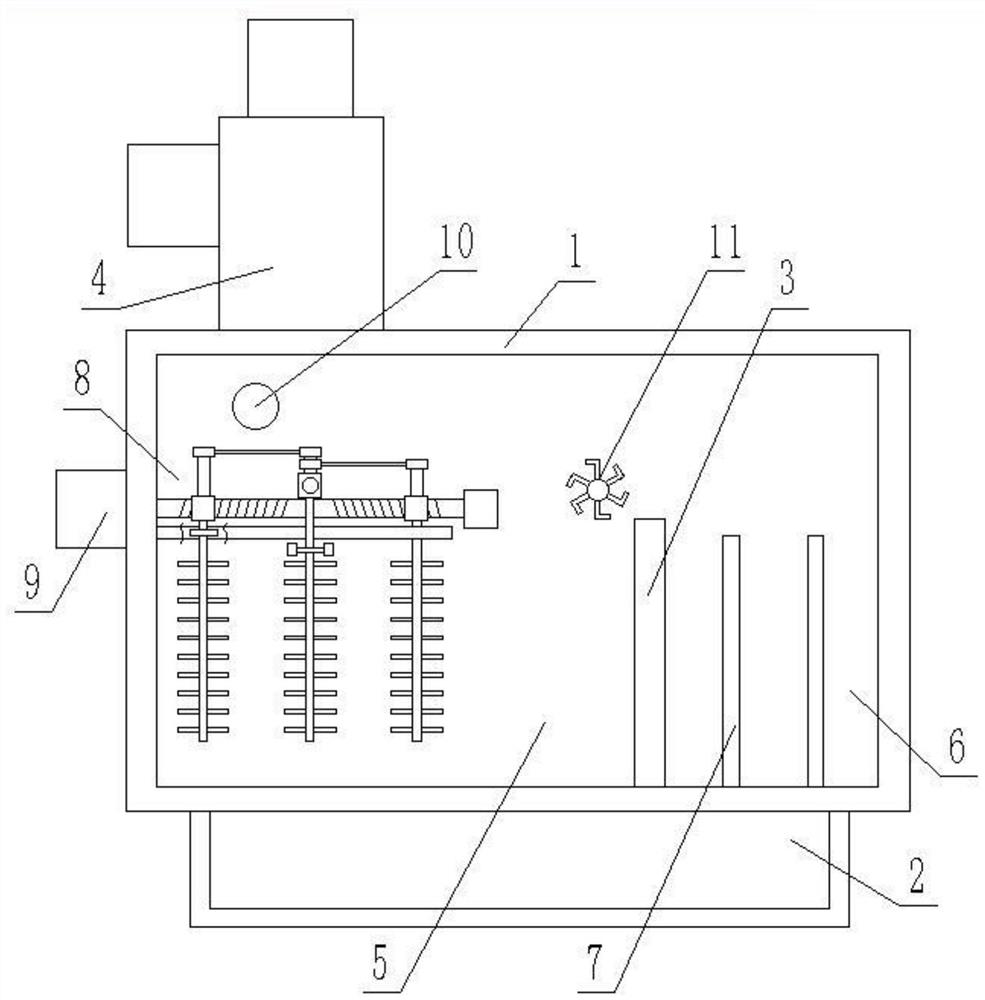

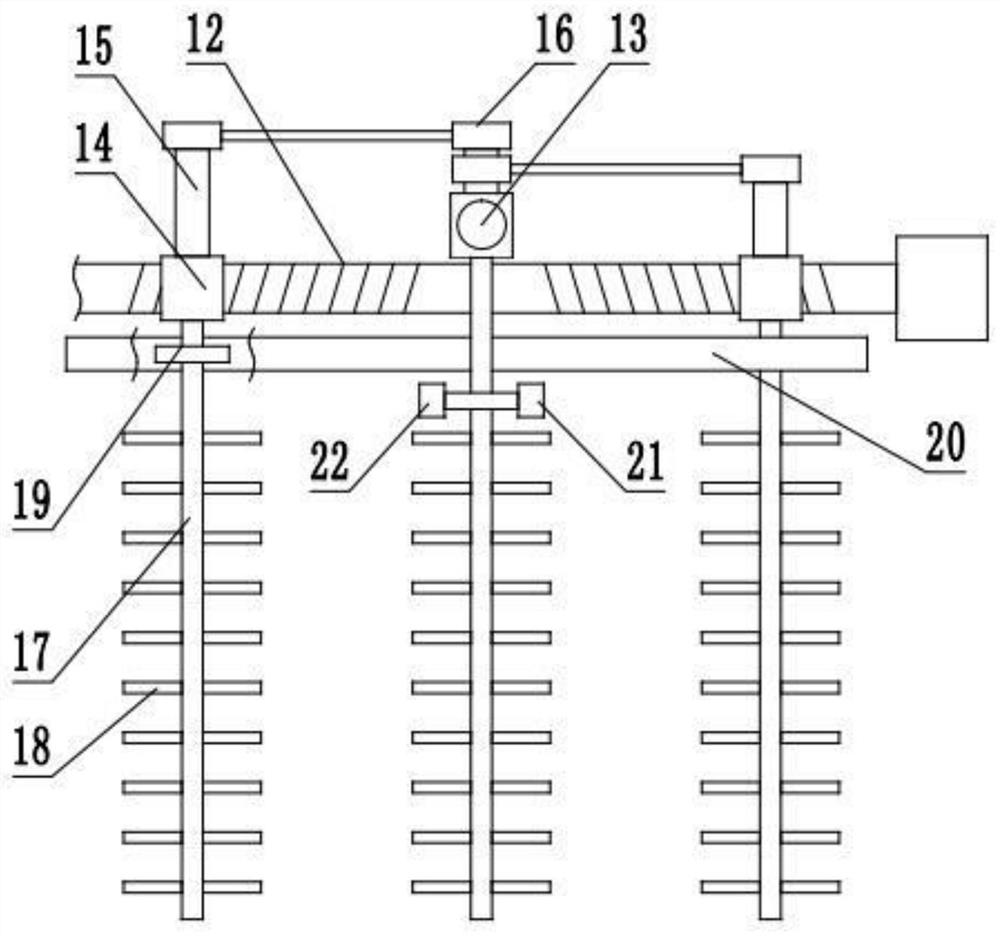

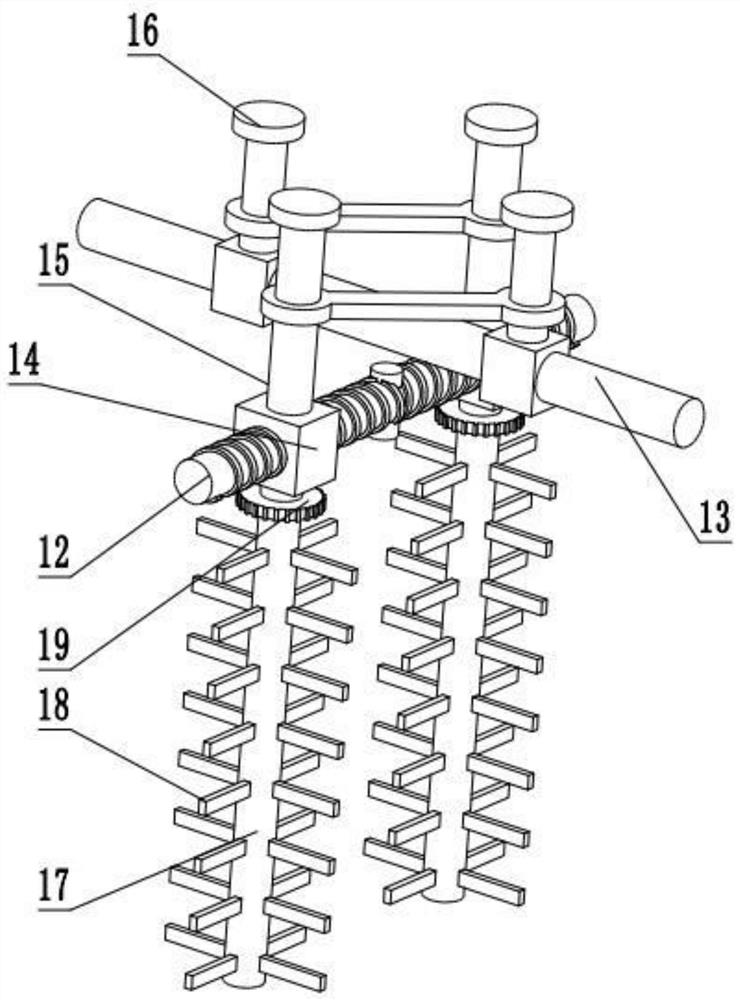

[0019] see Figure 1-3 , a rapid mixing type waste paper recovery deinking device, including a deinking box 1, a waste liquid box 2 and a waste paper input box 4, the waste liquid box 2 and the waste paper input box 4 are respectively located on the upper and lower sides of the deinking box 1 In the deinking tank 1, a partition 3 is arranged to divide the interior of the deinking tank 1 into two cavities connected at the top. The left side of the partition 3 is the mixing chamber 5, and the right side of the partition 3 is the transfer chamber 6. Stirring mixing chamber 5 communicates with waste paper input box 4, transfer chamber 6 communicates with waste liquid tank 2, agitator 8 is provided in stirring mixing chamber 5, and agitator 8 is provided on the outer wall of deinking tank 1. Connected pulse motor 9, the top of the deinking box 1 is also provided with a deinking agent input port 10, when the waste paper is being recycled, the waste paper is sent into the stirring mi...

Embodiment 2

[0023] refer to Figure 4, on the basis of Embodiment 1, the side of the waste paper input box 4 is provided with an inlet 23, and a crushing motor 24 is fixed on the top of the waste paper input box 4, and the output end of the crushing motor 24 is connected to a waste paper input The crushing shaft 25 in the box 4, the crushing shaft 25 is provided with a plurality of rotary blades 26, and on the side inner wall of the waste paper input box 4 away from the inlet 23, is provided with a plurality of fixed blades 27, the rotary blades 26 and the fixed blades 27 are arranged in a staggered manner. Before the deinking process, waste paper is put in from the inlet 23, the crushing motor 24 is started, and the waste paper is crushed by the rotating blade 26 and the fixed blade 27, thereby further improving the subsequent mixing efficiency and improving Deinking efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com