An automated rack plating pool

A technology of plating tank and transmission belt, applied in the direction of the plating tank, etc., can solve the problems of affecting the plating efficiency of other workpieces, the hooking of the workpiece is not firm, and the workpiece is easily detached from the hanger, etc., so as to ensure the efficiency of electroplating processing, reduce labor consumption, and avoid manual labor. The effect of the salvage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings.

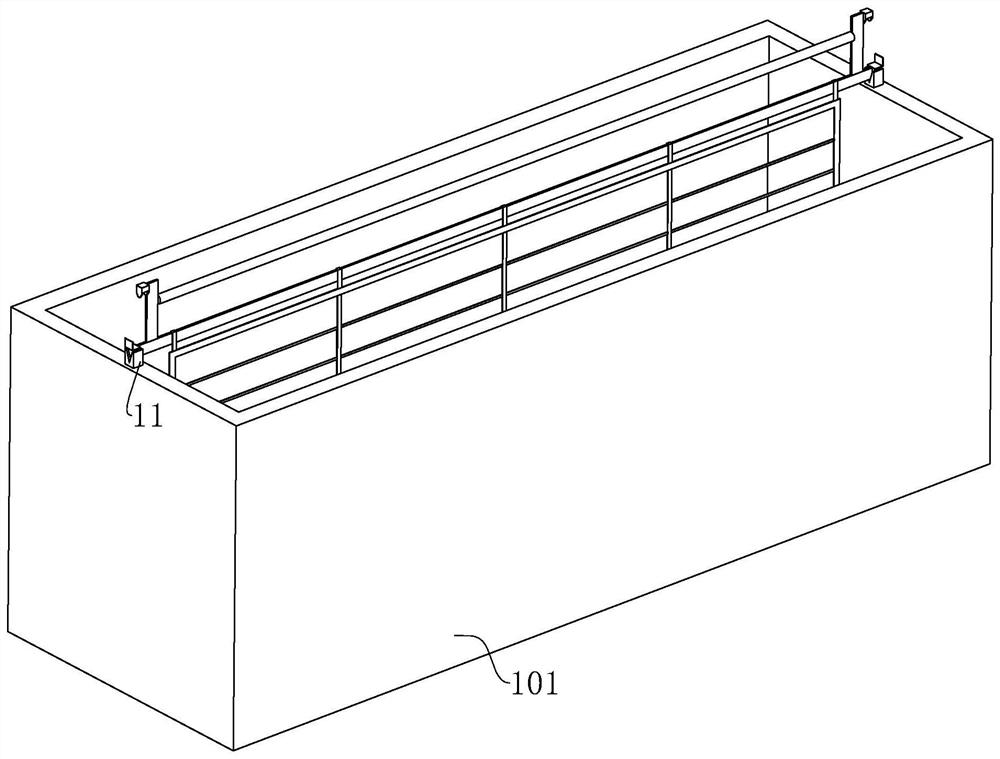

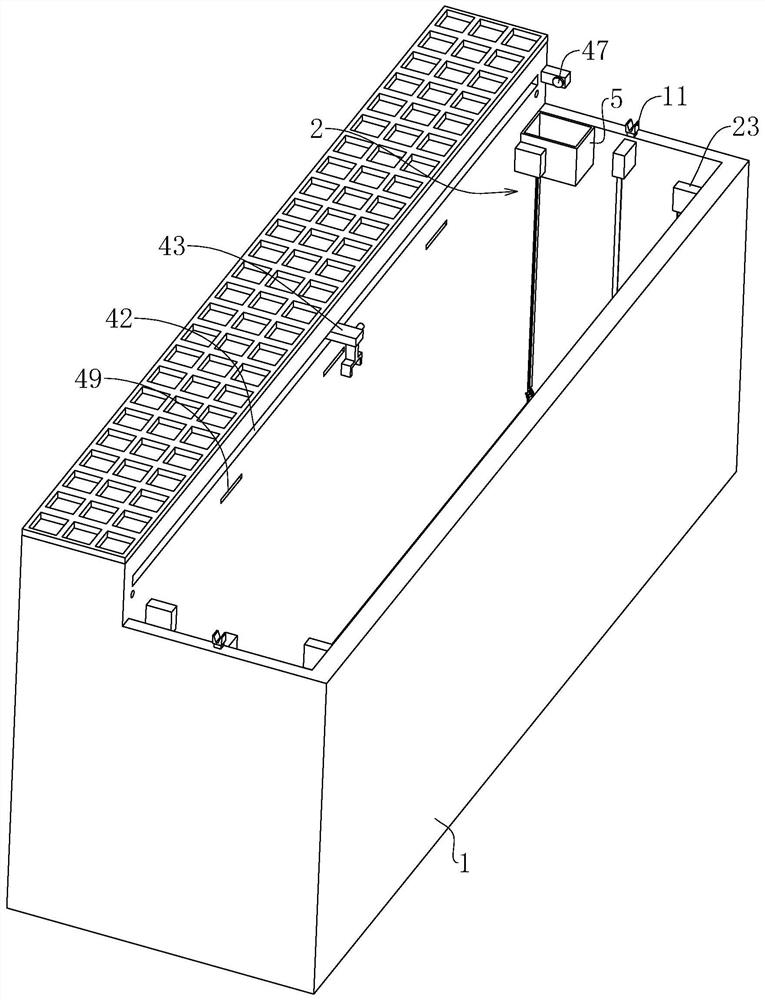

[0040] refer to figure 2 , is an automatic rack plating tank disclosed in the present invention, comprising a rack plating tank body 1, the rack plating tank body 1 is in the shape of a rectangular box as a whole, and the length of the cross section of the rack plating tank body 1 is 4 times the width of the cross section. The height of the plating tank body 1 is twice the cross-sectional width of the rack plating tank body 1 . The upper end of the rack plating tank body 1 is open and the inside is hollow, and the rack plating tank main body 1 is used for containing the solution.

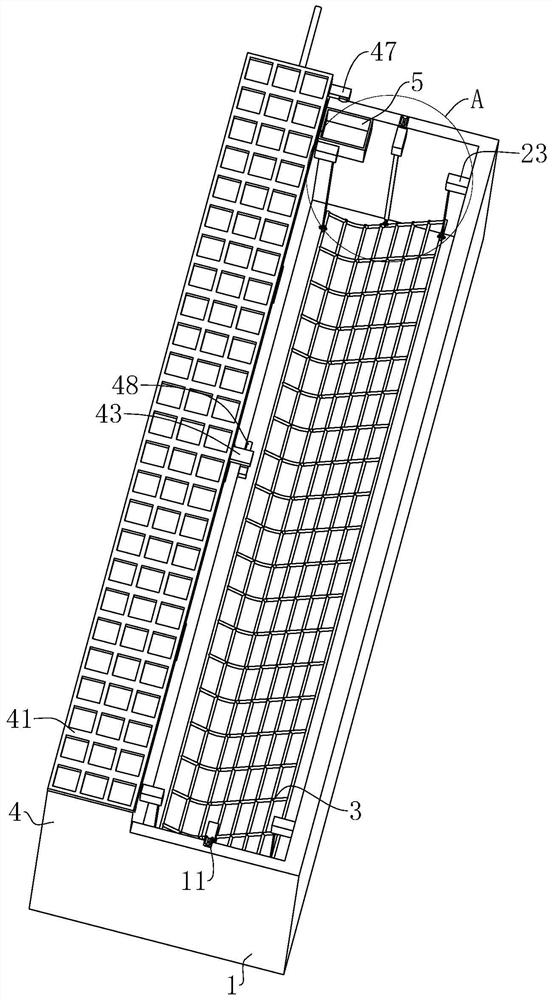

[0041] refer to image 3 , There is a salvage net 3 in the main body 1 of the hanging plating tank, and the salvage net 3 is rectangular as a whole. The vertical inner side walls of the rack plating tank body 1 are all connected with protective covers 23, and the protective cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com