Method of cultivating algae and photobioreactor

A technology of algae cells and cultures, applied in the field of cultivating algae, which can solve problems such as too much light and unhealthy growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

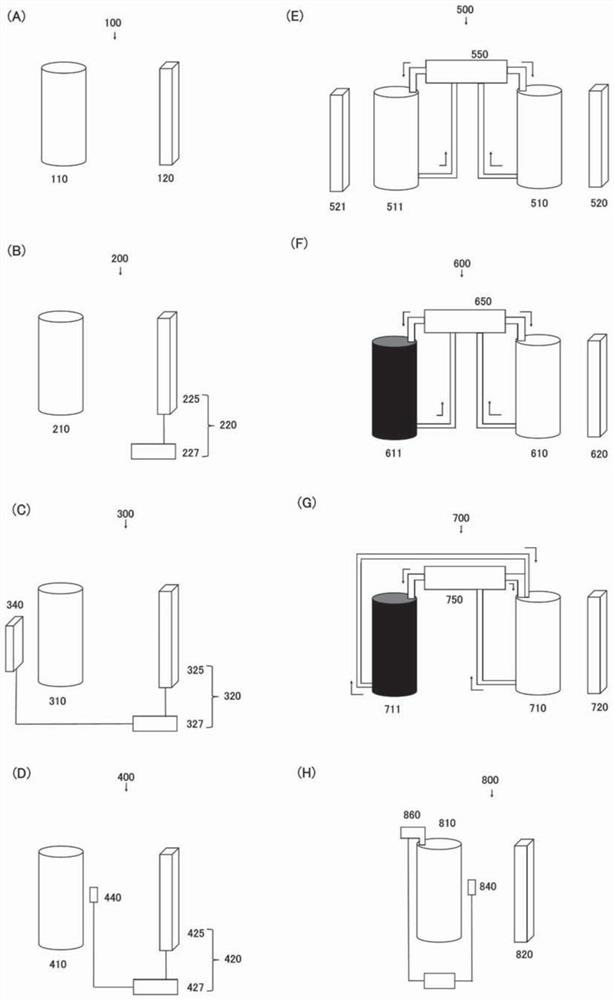

Image

Examples

preparation example Construction

[0157]

[0158] From another point of view, the present invention provides a method for preparing a cell culture of algae selected from the group consisting of green algae, euglena, diatoms, and dinoflagellates.

[0159] The method for producing a culture of algae cells of the present invention (hereinafter also referred to as "the production method of the present invention") is characterized in that the culture selected from green algae , euglena, diatoms, and dinoflagellates algae.

[0160] The algal cells used in the production method of the present invention are cells of algae selected from the group consisting of green algae, euglena, diatoms, and dinoflagellates as described in the above .

[0161] According to the production method of the present invention, it is possible (for example, from the viewpoint of time and / or cost) to produce a culture of algae cells efficiently and / or at a high density (that is, high biomass productivity can be achieved), Further, useful s...

Embodiment

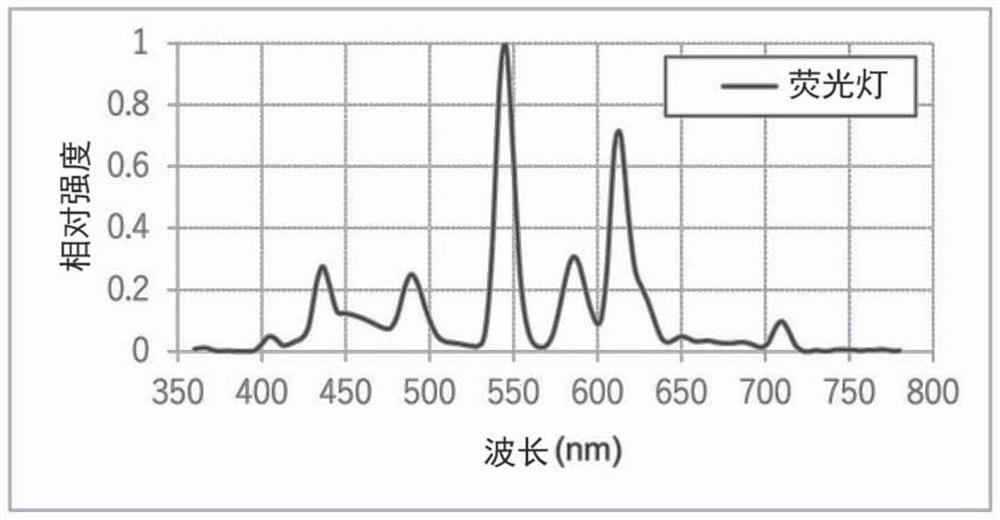

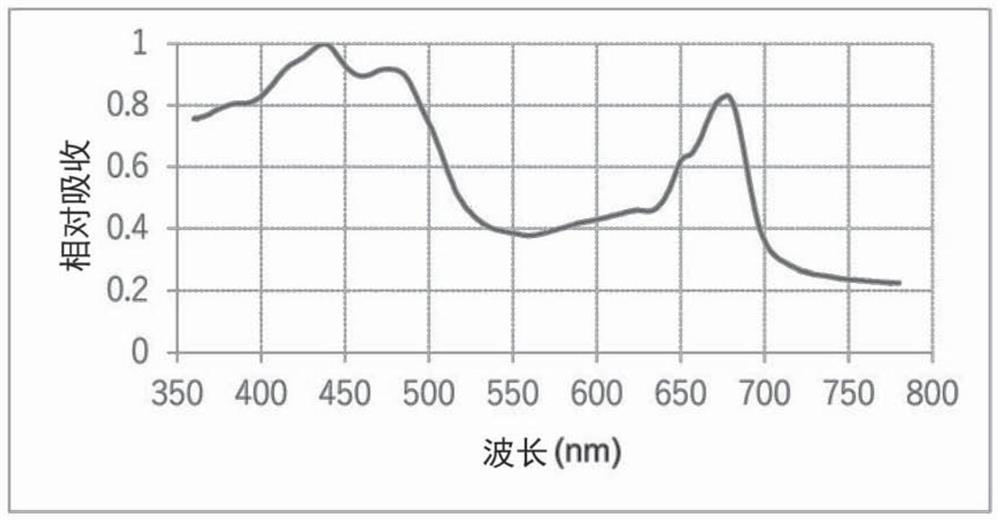

[0385] Experiment 1: Determination of Absorption Spectrum of Chlamydomonas

[0386] method:

[0387] Chlamydomonas reinhardtii CC-125 strain was pre-cultured for 3 days using a bottle-type photobioreactor under the following conditions.

[0388] pre-culture conditions

[0389] Light: white fluorescent lamp (optical quantum flux density: 200μmol / m 2 / s)

[0390] Medium: Change the amount of nitrogen source to 5 times (add NH 4 Cl to 2.5g / L) HSM medium 500mL

[0391] CO 2 Concentration: supply 2% CO to the medium at 0.1mL / mL medium / min 2 (v / v)

[0392] Temperature: 30°C

[0393] Stirring: 500rpm

[0394] After pre-cultivation, dilute to make the optical density (OD 750 )=0.4 (equivalent to 0.15 g / L in terms of dry weight), the main culture was carried out.

[0395] The main culture was carried out for 2 days under the following conditions.

[0396] Main culture condition (OD at the beginning 750 =0.4)

[0397] Light: white fluorescent lamp (optical quantum flux densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com