A method for extracting and separating eucommia gum from the feces of eucommia ulmoides larvae

A technology for Eucommia eucommia and Spodoptera eucommia, which is applied in the field of extraction and separation of natural product eucommia gum, can solve the problems of serious environmental pollution, serious structural changes of eucommia gum, long fermentation period, etc., so as to reduce costs and promote diversification. The effect of development and reduction of extraction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

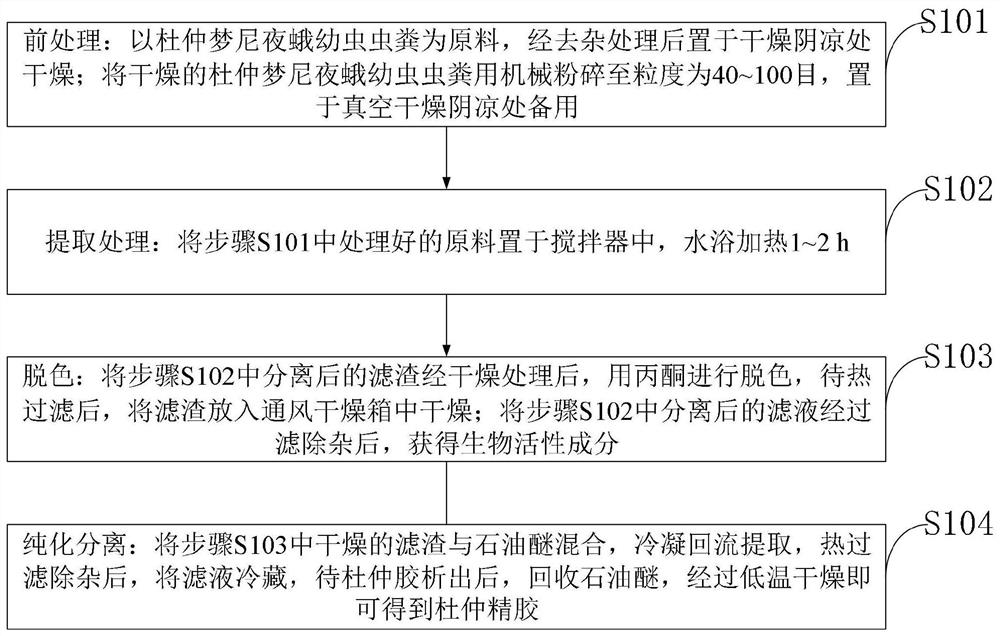

[0039] (1) Pre-treatment steps: place the larval excrement of Eucommia ulmoides larvae in a cool and ventilated place to dry after removing impurities; mechanically crush the dried larvae of Eucommia ulmoides larvae to a particle size of 40 mesh, place Store in a dry and cool place in vacuum.

[0040] (2) Water bath treatment step: add distilled water to the eucommia ulmoides larvae treated in step (1) fully according to the ratio of solid to liquid 1:10, and use a stirrer under the condition of rotating speed 300r / min and 50°C Heated in a water bath for 2h.

[0041](3) Decolorization: After drying the filter residue separated in step (2), mix it with acetone according to the ratio of solid to liquid 1:10, condense and extract at 70°C for 4 hours, and after hot filtration, put the filter residue drying in a ventilated drying oven; the filtrate separated in step (2) is filtered to remove impurities to obtain biologically active components;

[0042] The finished bioactive comp...

Embodiment 2

[0045] (1) Pre-treatment step: the larvae dung of Eucommia ulmoides, after removing impurities, is placed in a cool and ventilated place to dry; the dried larvae of Eucommia ulmoides is mechanically crushed to a particle size of 60 mesh, and placed Store in a dry and cool place in vacuum.

[0046] (2) Water bath treatment step: add distilled water to the Eucommia ulmoides larvae treated in step (1) fully according to the ratio of solid to liquid 1:15, and use a stirrer under the condition of rotating speed 200r / min and 40°C Heated in a water bath for 2h.

[0047] (3) Decolorization: After drying the filter residue separated in step (2), mix it with acetone according to the ratio of solid to liquid 1:15, condense and extract at 70°C for 3 hours, and after hot filtration, put the filter residue drying in a ventilated drying oven; the filtrate separated in step (2) is filtered to remove impurities to obtain biologically active components.

[0048] The finished bioactive ingredi...

Embodiment 3

[0051] (1) Pre-treatment steps: the larvae dung of Eucommia ulmoides, after removal of impurities, is placed in a cool and ventilated place to dry; the dried larvae of Eucommia ulmoides is mechanically crushed to a particle size of 100 mesh, and placed Store in a dry and cool place in vacuum.

[0052] (2) Water bath treatment step: add distilled water to the Eucommia ulmoides larvae treated in step (1) fully according to the ratio of solid to liquid 1:20, and use a stirrer under the condition of rotating speed 300r / min and 50°C Heat in a water bath for 1h.

[0053] (3) Decolorization: After drying the filter residue separated in step (2), mix it with acetone according to the ratio of solid to liquid 1:20, condense and extract at 70°C for 4 hours, and after hot filtration, put the filter residue drying in a ventilated drying oven; the filtrate separated in step (2) is filtered to remove impurities to obtain biologically active components;

[0054] The finished bioactive ingre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com