Negative electrode material and preparation method thereof, negative plate and lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of graphite-based negative electrode materials such as energy density, fast charging performance and high temperature performance that need to be further improved, and achieve the goal of improving fast charging performance, reduced rebound, and easy graphitization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

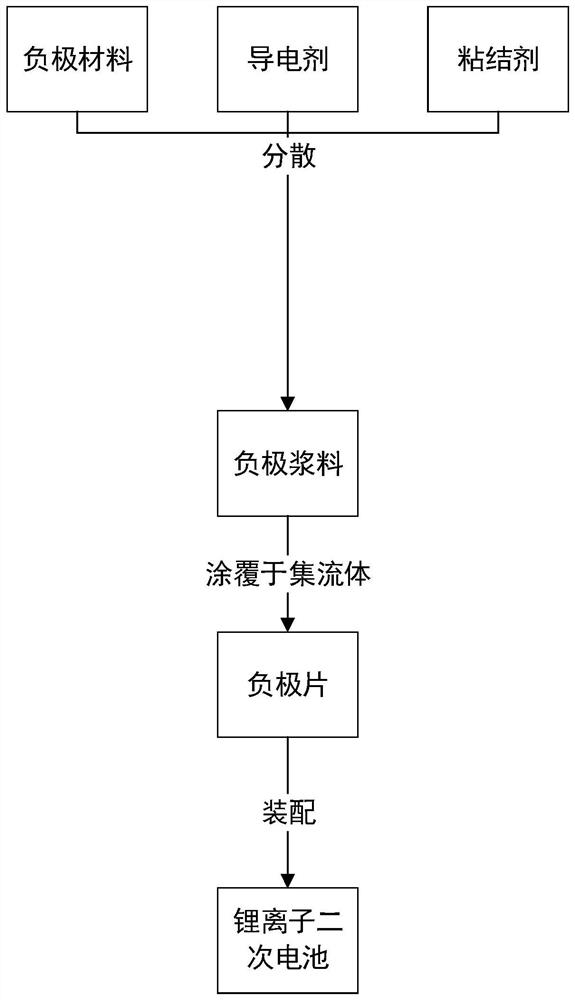

Method used

Image

Examples

Embodiment 1

[0060] The present embodiment provides a kind of preparation method of negative electrode material, and its specific method is:

[0061] (1) Coke materials (petroleum coke) with a crushed and shaped D50 of 15 μm and hard carbon (furfuryl ketone resin hard carbon) with a crushed and shaped D50 of 15 μm in a horizontal mixer (barrel volume of 200 L) A mixer with a maximum capacity of 250kg of material, the barrel speed is 17r / min, the blade speed is 35r / min) after mixing for 45min, add carbon-containing binder (asphalt), under a nitrogen atmosphere, at a rate of 3°C / min The heating rate is to raise the temperature to 600°C, and use a horizontal kettle (rotating speed frequency 25Hz) to carry out mechanical fusion granulation for 4 hours to obtain a granulated product;

[0062] Wherein, the mass of the hard carbon is 20% of the mass of the coke material, and the mass of the carbon-containing binder is 15% of the mass of the coke material;

[0063] (2) Under a nitrogen atmosphere...

Embodiment 2

[0068] The present embodiment provides a kind of preparation method of negative electrode material, and its specific method is:

[0069] (1) The crushed and shaped coke materials with a D50 of 8 μm (petroleum coke and coal coke with a mass ratio of 1:1) and the crushed and shaped hard carbon with a D50 of 18 μm (acrylic resin hard carbon) were placed in a horizontal After mixing for 35 minutes in a mixer (a mixer with a barrel volume of 200L, a maximum of 250kg of material, a barrel speed of 17r / min, and a blade speed of 35r / min), add a carbon-containing binder (coal tar), and mix in nitrogen gas. Under the atmosphere, the temperature was raised to 550°C at a heating rate of 4°C / min, and mechanical fusion granulation was carried out for 3 hours in a horizontal kettle (rotational frequency 25Hz) to obtain a granulated product;

[0070] Wherein, the mass of the hard carbon is 30% of the mass of the coke material, and the mass of the carbon-containing binder is 10% of the mass of...

Embodiment 3

[0074] The present embodiment provides a kind of preparation method of negative electrode material, and its specific method is:

[0075] (1) Put coke material (coal char) with a D50 of 10 μm after crushing and shaping and hard carbon (phenolic resin hard carbon) with a D50 of 10 μm through crushing and shaping in a horizontal mixer (barrel volume of 200 L) Mixer, with a maximum capacity of 250kg of material, the barrel speed is 15r / min, the blade speed is 40r / min), after mixing for 30min, add carbon-containing binder (polypropylene emulsion), under nitrogen atmosphere, at 2°C / min The heating rate was increased to 500°C, and mechanical fusion granulation was carried out for 6 hours using a horizontal kettle (rotating speed frequency 10Hz) to obtain a granulated product;

[0076] Wherein, the mass of the hard carbon is 10% of the mass of the coke material, and the mass of the carbon-containing binder is 5% of the mass of the coke material;

[0077] (2) Graphitizing the granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com