Automobile composite pedestrian protection beam

A composite material and pedestrian protection technology, applied in pedestrian/occupant safety arrangement, bumper, vehicle parts, etc., can solve the problems of small living space for pedestrians, insufficient material strength, large local deformation, etc., and achieve low preparation cost and advanced performance , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Attached below Figure 1-8 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

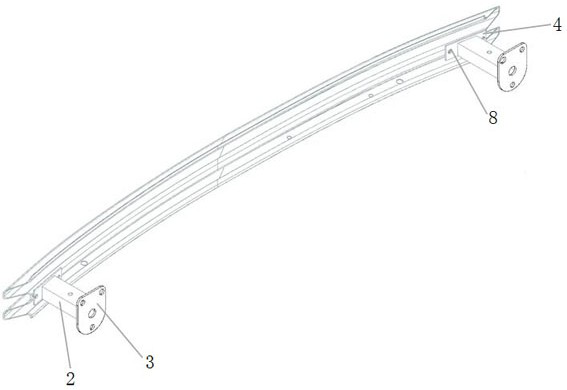

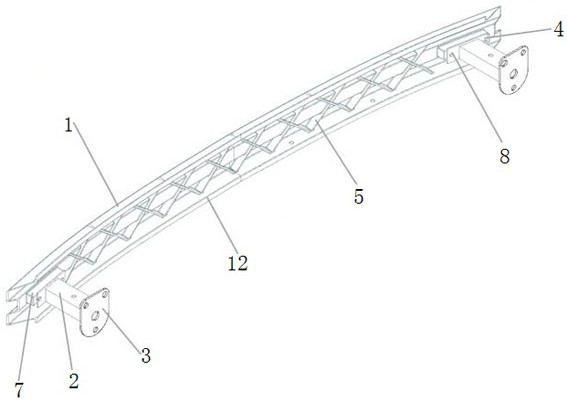

[0029] In order to ensure the structural strength of the automobile pedestrian protection beam while achieving light weight, and improve the safety protection factor during use, this embodiment discloses an automobile composite material pedestrian protection beam structure, including a protection beam body 1 and an energy-absorbing box 2 , negative sheet 3 and metal aluminum sheet 4, the protective beam body 1 is integrally molded, the main body shape of the protective beam body 1 is similar to the existing protective beam so as to be suitable for the installation position and installation requirements on the original vehicle type, and the protective beam body One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com