Volumetric weighing and distributing device and distributing method thereof

A technology of distributing device and weighing device, applied in the field of powder metallurgy, can solve the problems of low content of finished raw materials, affecting the quality of finished products, not filled with powder materials, etc., to achieve the effect of accurate weight and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

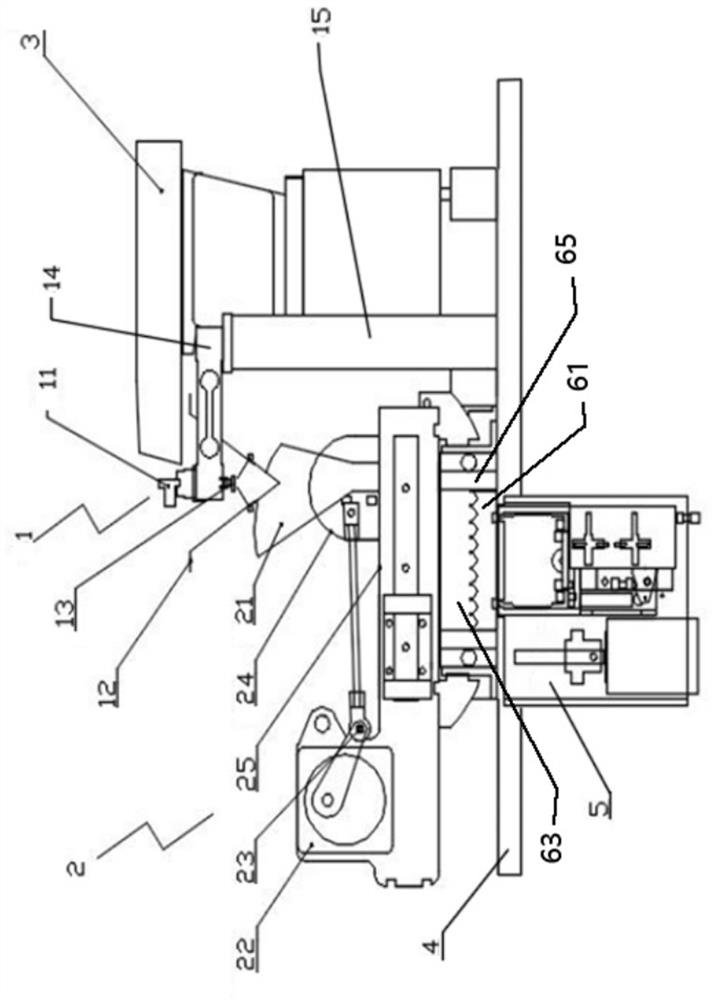

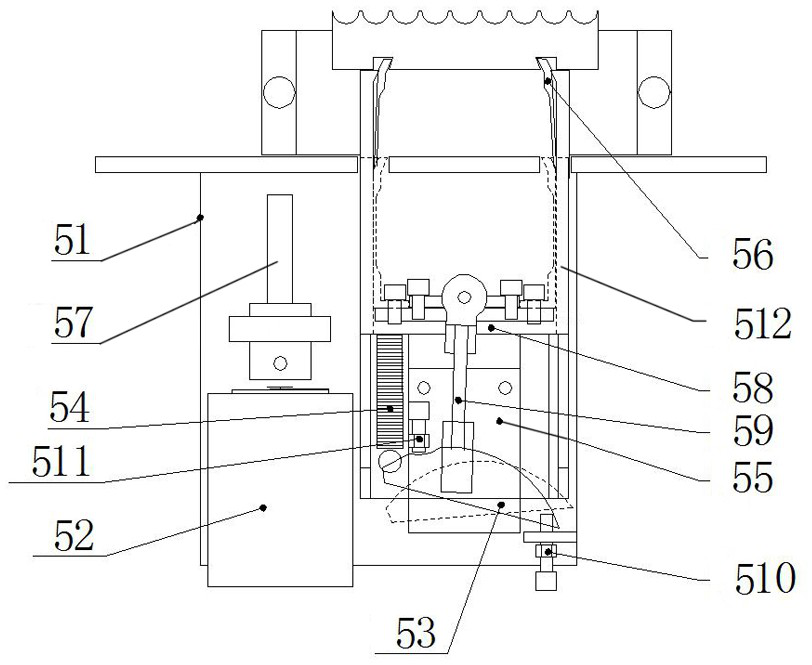

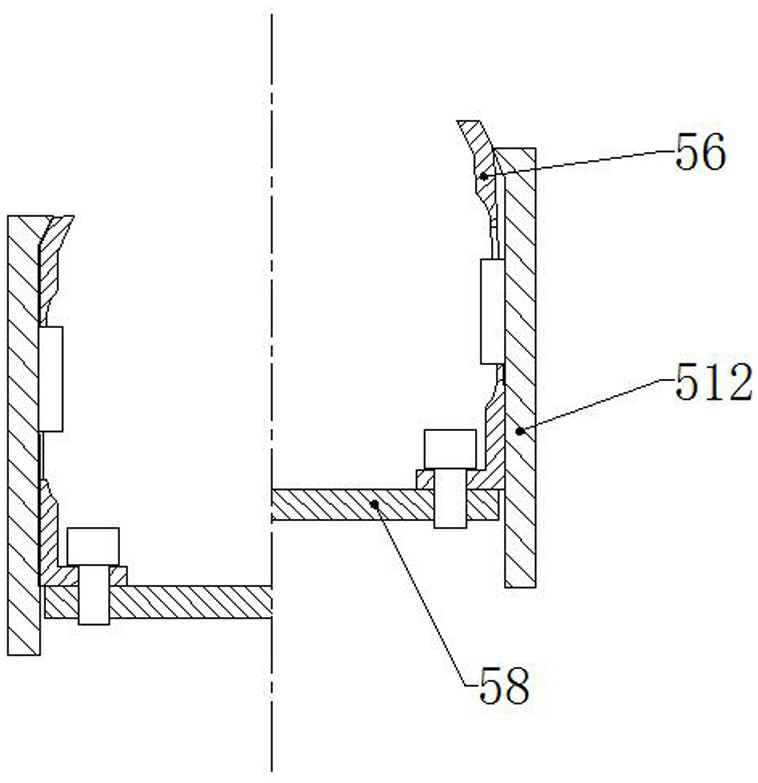

[0026] like Figure 1 to Figure 6 A volumetric weighing and distributing device shown includes a weighing device 1, a distributing mechanism 2, a feeding vibrating plate 3, a working platform 4, an ejection mechanism 5 and a dry pressing molding die 6, wherein: the distributing mechanism 2 is installed On the working platform 4, the dry pressing mold 6 is set under the material distribution mechanism 2, the weighing device 1 is set above the material distribution mechanism 2, the feeding vibrating plate 3 is set above the weighing device 1, and the ejection mechanism 5 is set on the On the lower surface of the working platform 4 and below the cloth mechanism 2;

[0027] Described dry press forming mold 6 comprises mold base 61, mold cover body 62 and mold frame 65, and mold base 61 and mold cover body 62 are installed in mold frame 65, on described mold base 61 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com