Automatic rice distribution system for student canteens

A technology for canteens and students, applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve problems such as low accuracy, large impact on accuracy, and complex mechanisms. Accurate weight, improved efficiency, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

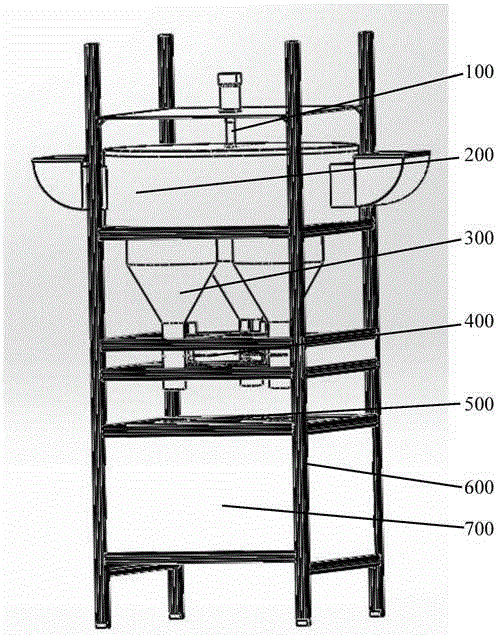

[0056] Such as Figure 1 to Figure 5 Shown:

[0057] The present invention includes an integral frame 600, which includes a stirring mechanism 100, a rice container 200, three sets of rice leakage devices 300, three sets of rice leakage outlet opening and closing devices 400, and three signal detection modules from top to bottom. 500 and single-chip microcomputer control system 700; three sets of rice leaking devices 300, three sets of rice leaking outlet opening and closing devices 400, and three signal detection modules 500 are in one-to-one correspondence. The stirring mechanism 100 is connected to a power supply, and the rice leaking The exit opening and closing device 400 and the signal detection modules (three) 500 are respectively connected with the single chip controller 700 .

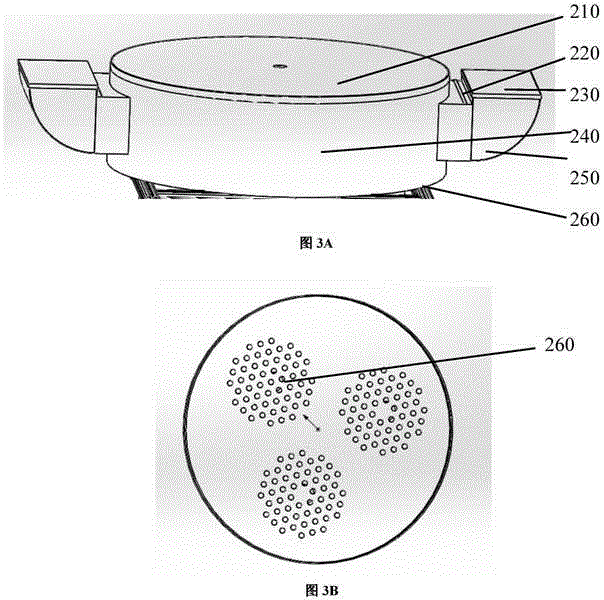

[0058] Such as figure 2 Shown:

[0059] The stirring mechanism 100 of the present invention includes a speed regulating motor 130 , a connecting shaft 110 and a stirrer 120 , one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com